Roccia Rundbiegen represents the perfect balance between productivity, versatility and accuracy. Machines designed for PERFECTION.

Italian style, German technology: electronic precision, hydraulic power, mechanical strength for hydraulic plate rolling machine, angle roll machine, bending roll machine and more…

Let our team show you the innovative products and features Roccia Rundbiegen has to offer.

2 ROLL PLATE BENDING MACHINE

FAST, PRECISE AND EASY TO USE

Fast and easy to use the 2 roll plate bending machine is the best solution to roll thin plates out of very small diameters. The Roccia HR2W is composed by a solid electro welded frame accurately machined on CNC boring machines to achieve the precision and stiffness that is typical of Roccia machines. This is a very important factor for a machine that grants a precision of 0.1 mm on rolling diameters. The typical thickness for these machines goes from 0.2 up to 3mm, in some special cases even up to 4mm and for plates of a width from 50mm up to 2000mm. The urethane lower roll works like a matrix and the top roll like a die as to imprint the shell radius. To change the radius is as easy as to install a mandrel or former roll onto the top roll. This is absolutely the quickest machine that the market can offer as it reaches productions of over 250 parts per hour. Roccia HR2W is typically supplied with a wide range of accessories like vacuum conveyor part ejector and welding system and it can be fully automated.

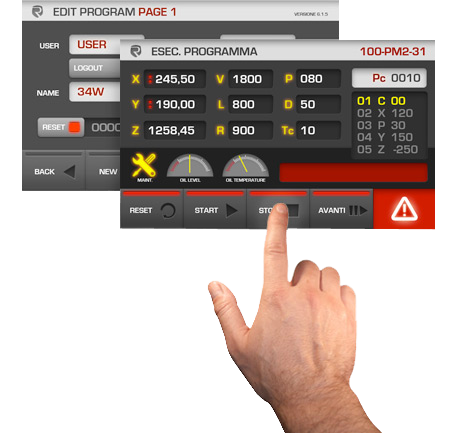

ERGONOMIC CONTROL PANEL: As place your hands on the control console, you will immediately be aware that all the controls are exactly where you would expect them to be.

To request information on Roccia 2 Roll Plate benders contact our sales department at sales@heritagemachinery.com or call 248-693-4796

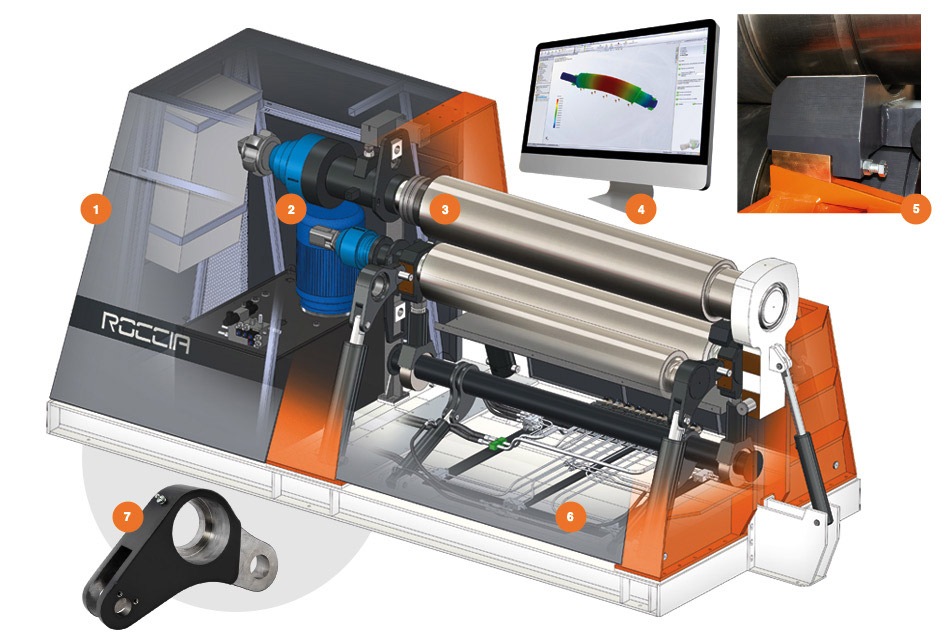

3 ROLL PLATE BENDING MACHINE – HR3WR

HR3WR 3 rolls

THE MOST VERSATILE 3 ROLL PLATE BENDING MACHINE

FEATURES:

Single unit high torque hydraulic MOTORS/PLANETARY GEARBOXES are directly mounted onto each driving roll to ensure a smooth feed through of the plate, there is no loss of power normally associated with secondary transmissions, plus the added benefit of one less gearbox to maintain.

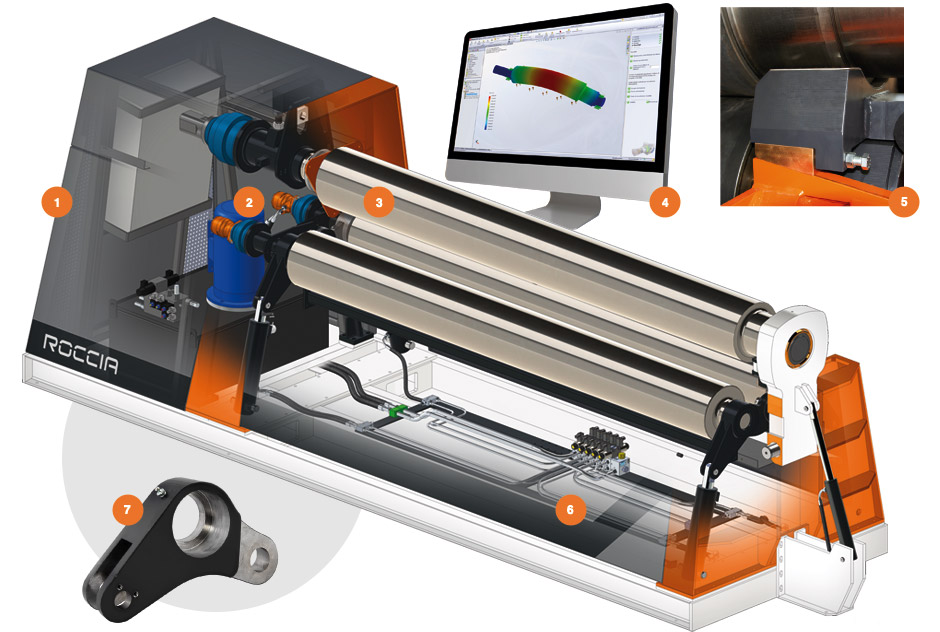

3) ROLL DESIGN CALCULATION. It is the heart of the machines performance; it’s what makes a ROCCIA plate roll different from the competition.

4) ROLL CAMBER CALCULATION. Roll camber is required to counter act roll deflection that occurs as bending forces are applied, so as to ensure a perfect closing of the longitudinal seam, it is a vitally important factor. If the camber is calculated incorrectly, the result will be, (1) a barrel shaped cylinder is not closing perfectly along the longitudinal seam, gap in the middle, (2) an hour glass shaped cylinder, the longitudinal seam touching in the middle, but not at the ends.

ROCCIA roll dimensioning camber calculation are done on sophisticated 3D cad software that produces all the critical data required for every step of the rolling process. Roll calculations are seldom to standard formulae, no, they are calculated around customer requirements, this being, material type, mechanical strength, material thickness, the rolls cylinder length dimension.

Only this way can we grant the performance and the precision of the plate rolling machine we manufacture for you.

5) Roccia engineers have designed a new and exclusive heavy duty CONE ROLLING DEVICE, that is mounted or bolted or positioned into the machine hard against the bottom roll shoulder to eliminate possible movement.

The MECHANICAL ADJUSTMENT OF THE PINCHING lower roll [MAP] in conjunction with the powerful thrust of the 2 side bending rolls during the pre bend cycle ensures a minimal flat along the longitudinal edge.

This design solution offers a smooth friction free movement for each side roll, a friction less system has the advantages of; more pre bending power, a maintenance free longer life unit.

ERGONOMIC CONTROL PANEL. As place your hands on the control console, you will immediately be aware that all the controls are exactly where you would expect them to be.

3 ROLL BENDING MACHINE – VARIABLE GEOMERY

THE MOST ADVANCED 3 ROLL BENDING MACHINE

3 roll variable axis plate bending machines are used for bending medium to thick plates. They are very precise and easy to use. There are advantages by using this system where the two side rolls move horizontally – left and right, while the top roll moves up and down. When feeding the material into the machine it does not tilt up like it would on a double pinch three roll bender, but stays parallel to the ground allowing easier and safer material handling. When positioning the side rolls at their farthest position, you can increase the rolling capacity by up to 50% more than on a traditional 3 or 4 roll bending machine. Three driving rolls offer full control over the bending process.

FEATURES:

This system is clean, maintenance free and efficient. By not using gears or chains you will not have a loss in torque as you would in an ordinary transmission driven plate bender. The hydraulic motors and gear boxes are coupled directly on the rolls.

Roll camber calculation. Roll camber is required to counter act roll deflection that occurs as bending forces are applied, so as to ensure a perfect closing of the longitudinal seam, it is a vitally important factor. If the camber is calculated incorrectly, the result will be, (1) a barrel shaped cylinder ie not closing perfectly along the longitudinal seam, gap in the middle, (2) an hour glass shaped cylinder, the longitudinal seam touching in the middle, but not at the ends. ROCCIA roll dimensioning camber calculation are done on sophisticated 3D cad software that produces all the critical data required for every step of the rolling process. Roll calculations are seldom to standard formulae, no, they are calculated around customer requirements, this being, material type, mechanical strength, material thickness, the rolls cylinder length dimension. Only this way can we grant the performance and the precision of the plate rolling machine we manufacture for you.

ERGONOMIC CONTROL PANEL. As place your hands on the control console, you will immediately be aware that all the controls are exactly where you would expect them to be.

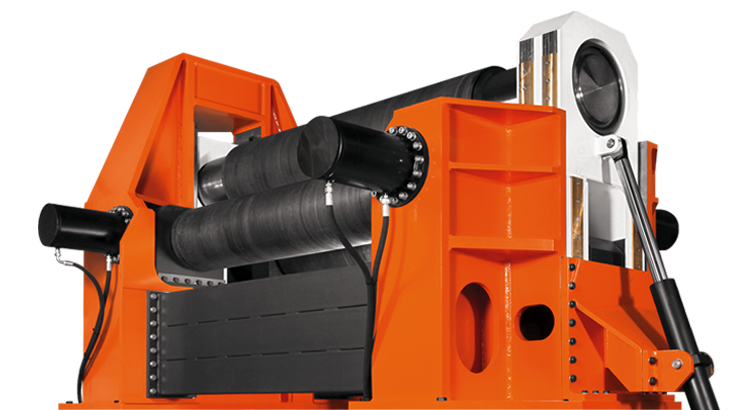

4 ROLL PLATE BENDING MACHINE – HR4WR

HR4WR 4 ROLLS

4 ROLL PLATE BENDING MACHINE

THE FASTER AND MOST AUTOMATED.

FEATURES:

1) The wide BASED ANGLED FRAME bulkhead construction is designed to bring increased stability to the whole structure, designed by ROCCIA engineers to absorb side thrust forces during plate rolling cycles.

2) A Roccia four roll bending machine utilizes 2 driven rolls to ensure the rolling torque power transfer. This way a strong material grip is assured between top roll and lower roll with the [MAP] material pinching system.

Single unit high torque hydraulic MOTORS/PLANETARY GEARBOXES are directly mounted onto each driving roll to ensure a smooth feed through of the plate, there is no loss of power normally associated with secondary transmissions, plus the added benefit of one less gearbox to maintain.

3) ROLL DESIGN CALCULATION. It is the heart of the machines performance; it’s what makes a ROCCIA plate roll different from the competition.

4) ROLL CAMBER CALCULATION. Roll camber is required to counter act roll deflection that occurs as bending forces are applied, so as to ensure a perfect closing of the longitudinal seam, it is a vitally important factor. If the camber is calculated incorrectly, the result will be, (1) a barrel shaped cylinder is not closing perfectly along the longitudinal seam, gap in the middle, (2) an hour glass shaped cylinder, the longitudinal seam touching in the middle, but not at the ends.

ROCCIA roll dimensioning camber calculation are done on sophisticated 3D cad software that produces all the critical data required for every step of the rolling process. Roll calculations are seldom to standard formulae, no, they are calculated around customer requirements, this being, material type, mechanical strength, material thickness, the rolls cylinder length dimension.

Only this way can we grant the performance and the precision of the plate rolling machine we manufacture for you.

5) Roccia engineers have designed a new and exclusive heavy duty CONE ROLLING DEVICE, that is mounted or bolted or positioned into the machine hard against the bottom roll shoulder to eliminate possible movement.

The MECHANICAL ADJUSTMENT OF THE PINCHING lower roll [MAP] in conjunction with the powerful thrust of the 2 side bending rolls during the pre bend cycle ensures a minimal flat along the longitudinal edge.

6) CLEANLINESS AND ORDER in the hydraulic and electrical parts of our machine express the attention to detail we put into our product.

7) ROCCIA plate bending rolls use SWING ARM TECHNOLOGY for the movement of the side bending rolls. Each swing arm is manufactured from a solid steel profile this ensures rigidity.

This design solution offers a smooth friction free movement for each side roll, a friction less system has the advantages of; more pre bending power, a maintenance free longer life unit.

ERGONOMIC CONTROL PANEL. As place your hands on the control console, you will immediately be aware that all the controls are exactly where you would expect them to be.

ANGLE ROLL – BENDING PIPE, ANGLES AND BEAMS

BENDING PIPE, ANGLES AND BEAMS

Full hydraulic machines with three driven rolls with independent hydraulic motors and two bending rolls driven by massive hydraulic pistons. Roccia SR3W are developed on modern 3D CAD CAM stations to grant the structural stiffness typical of every Roccia machine and to develop the right geometry necessary to achieve a smooth and linear profile bending process.

The rolls are assembled on rigid electro welded frames machined on CNC boring machines to grant the precision that every Roccia machine offers even when pushed to their limit.

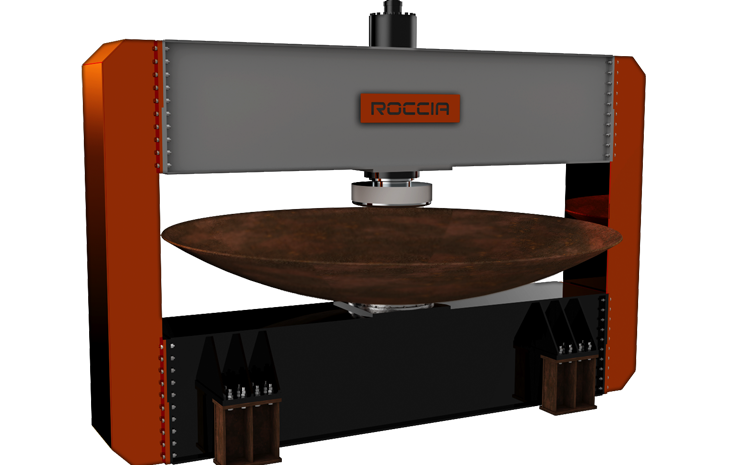

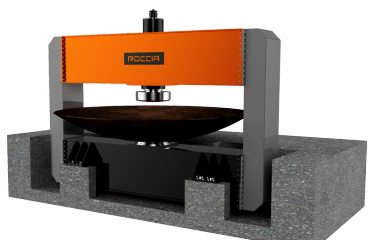

DISHED HEADS – DISHED ENDS MACHINES

DISHED HEADS / DISHED ENDS MACHINES

POWER AND PRECISION

The machine frame built of high strength materials by Mig welding. The frame welded and stress relieved prior to machining in order to meet tight manufacturing tolerances for appropriate assembling and maintenance.

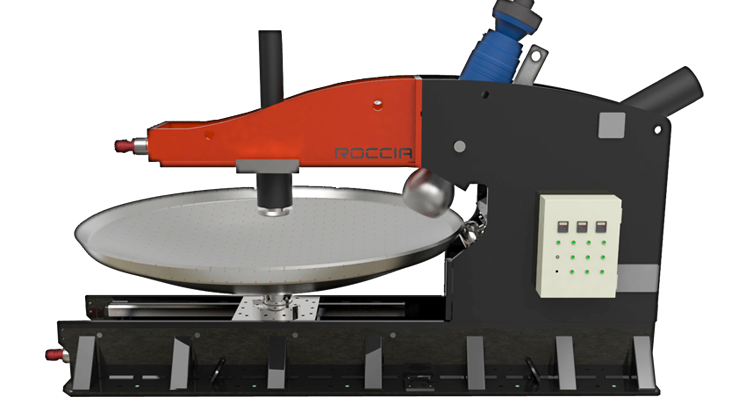

FLANGING MACHINES

HIGH QUALITY FLANGING MACHINE

Roccia flanging machines to form dished ends up to 50mm of thickness.

LEVELING MACHINES

Straightening machines

High strength electro-welded frames, machined on sophisticated CNC boring and milling centers, to get perfect and durable couplings between the parts.

Powerful and solid traction of the rolls with two different drives systems, depending on the size of the machine:

- gear transmission box containing oil bath traction gears having millesimal precision couplings to avoid power loss during the straightening process

- gearboxes directly coupled to each straightening roll, for bigger machines needing higher traction forces

The rolls are coupled with our exclusive “easy fix” system, in order to have them easily removed for maintenance or system cleaning operations. Each of our straightening machines can be equipped with our exclusive “plug & play” system as well as with our CNC-Str control, to produce parts in automatic mode.

Straightening plates has never been so easy and efficient with our STR machines…

.

CNC SYSTEMS – COMPUTER NUMERICAL CONTROL

Three different software options for three different levels of CNC control. Written and then fully tested and optimized on our plate rolling machines, by our team of engineers, always with our customers requirements to the forefront. The layout of every operation function window is clear and user friendly.

GALILEO

With a 12” touchscreen full colour monitor Galileo offers a user friendly software. It can be programmed by writing all the steps you want the machine to perform, or just in auto teaching mode, where you actually bend a plate, creating the program as you go, step by step. You can then repeat the same program whenever you have to produce the same part. You can store up to 1000 programs but if you have more to save you can use the USB port to save your programs on a USBdrive, this way you can store your programs on your PC and get an unlimited storage capacity. Galileo is a good starting point where you need to automate a machine but you have budgetary considerations.

NEWTON

The Newton CNC control is capable of auto calculating the position and movement of the machine, simply by just inserting the radius and details of the material you want to bend. On the large 15” touch screen full color monitor you can type and do all the required process and some elements of the machine maintenance. The memory capacity is unlimited and it offers via a USB port a wifi e connection so that ROCCIA can offer remote assistance. A good graphic user friendly software it is easy and intuitive to use and offers a solution to all of the most common bending problems. It’s a good balance between performance and price.

GIOTTO

Giotto is one of the most sophisticate systems you can find in the market. Like all other CNC we offer it’s has been developed on ROCCIA machines by our team of engineers, so it isn’t just an adaptation of a commercial system, it is a dedicate piece of software that has been specifically developed to produce the best possible methods to roll plate.

15” touch screen full color monitor with superb graphic features where you can visualize “ to scale” the part you are programming before actually producing it. One of the best features is the possibility to load into the system the DXF files, it handles them up to writing the program without further information from the operator. The movements are all proportional, it is an interpolate system so that more than two axis can be positioned at the same time. This is necessary for instance to bend ellipses or in all cases where a junction between one radius to another can be an issue.

It is absolutely a good working companion that offers valuable and innovative solutions.