About Memoli:

Founded in 1967, the MEMOLI Company has been manufacturing bending machines ever since, for more than 55 years. The Company started as a small craftsmen workshop which then developed its technologies and products to suit them to nowadays requirements.

Mechanical Design:

Each Memoli machine is a unique and customized product, specifically designed to fulfill every single Customer’s needs and resulted from the multiple possible combinations of models, sizes and equipment.

Our commitment is constantly oriented at Customer satisfaction, because we believe in a long-lasting relationship with our dealers and our direct user Clients.

Production:

Made in Italy products are a guarantee: high quality and security standards mark Memoli machinery as a product of excellence, thanks to the long time expertise gained through decades in manufacturing machines capable of becoming really favorable solutions for the market requirements.

We also offer a consulting service through our internal technical department, which is always available to study and find out the best possible solution: our goal is actually our Customer’s complete satisfaction.

To request information on any Memoli machine click the button below.

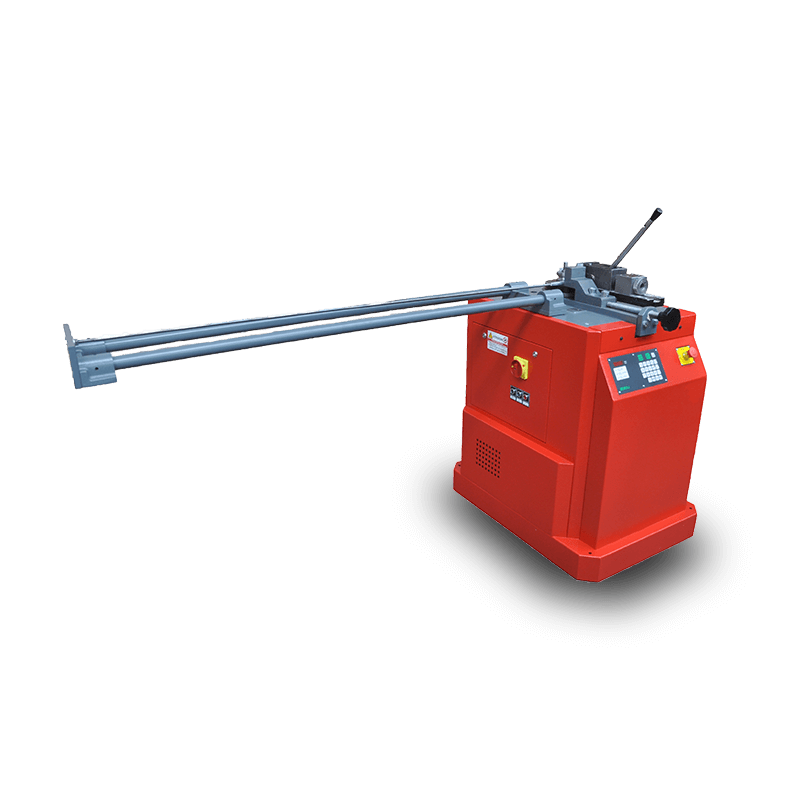

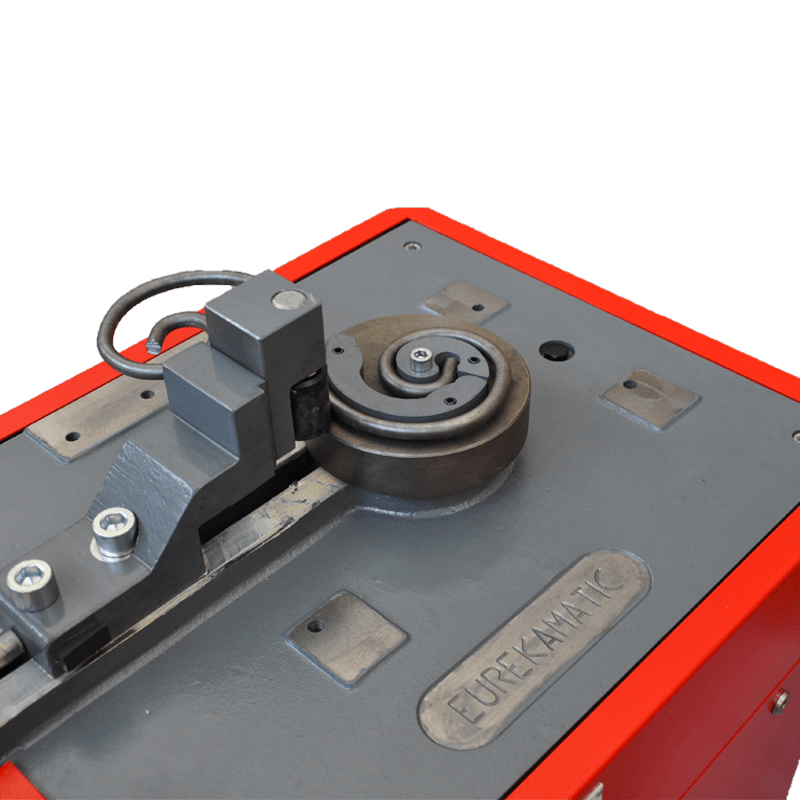

EUREKAMATIC Universal Bender

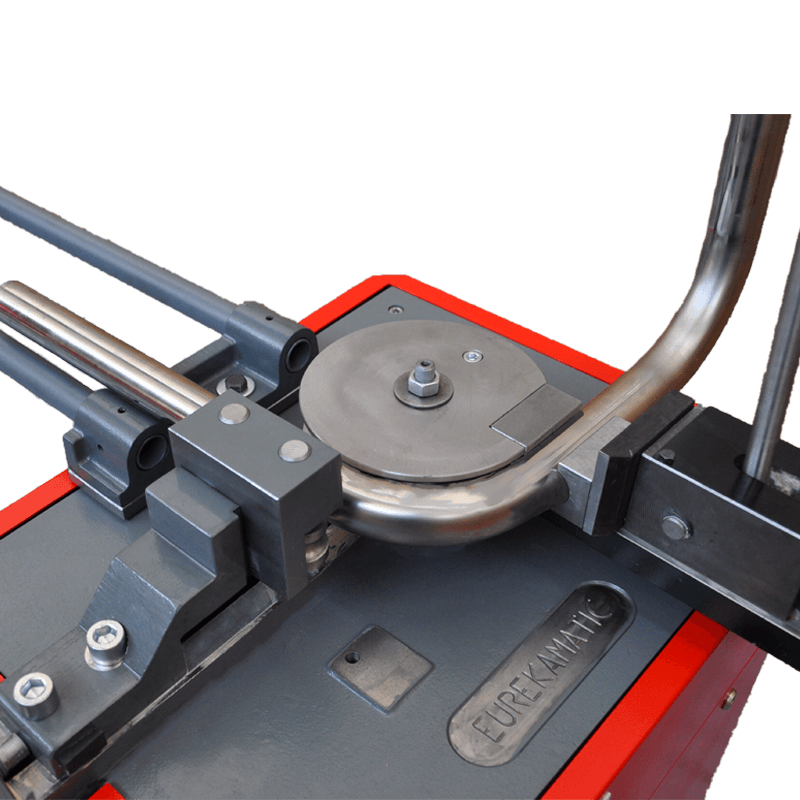

One machine only for 4 different operations: circle-curve bending, angle-bending, tube bending with two options to bend with or without mandrel and scroll-bending.

Machined from solid cast iron block and designed to work cold iron, it is extremely easy to use because it is run and aided by an incorporated software, which allows total precision and efficiency of the curving system. The display shows the desired angle of curvature and constantly informs the operator about the position and movements of the curving axis.

The software allows the storage of 45 different angles of curvature. It is very easy and fast to change toolings. The machine can work both in manual and in semi-automatic mode, thus reducing working times and error possibility. It is also possible to have the clamping vice either pneumatic or hydraulic, besides some more customized options depending on the Customer’s specific needs.

CONTROL PANEL

-

User-friendly

-

Digital screen

-

Tactile keyboard

-

RAM

-

Safety-mode

Eurekamatic has been for many years so far one of the most requested and used machines by blacksmiths for their applications on tubes, profiles and square tubes, in order to carry out railings, handrails, tables, chairs, doors, windows, gratings and many more.

TECHNICAL SPECIFICATION

|

MOTOR POWER |

KW 4 |

|---|---|

|

Rotation Speed |

7 - 14 g/1’ |

|

Gears |

Run in Oil Bath |

|

Weight |

280 kg |

|

Size |

850 x 620 x 980 h. |

Watch the video

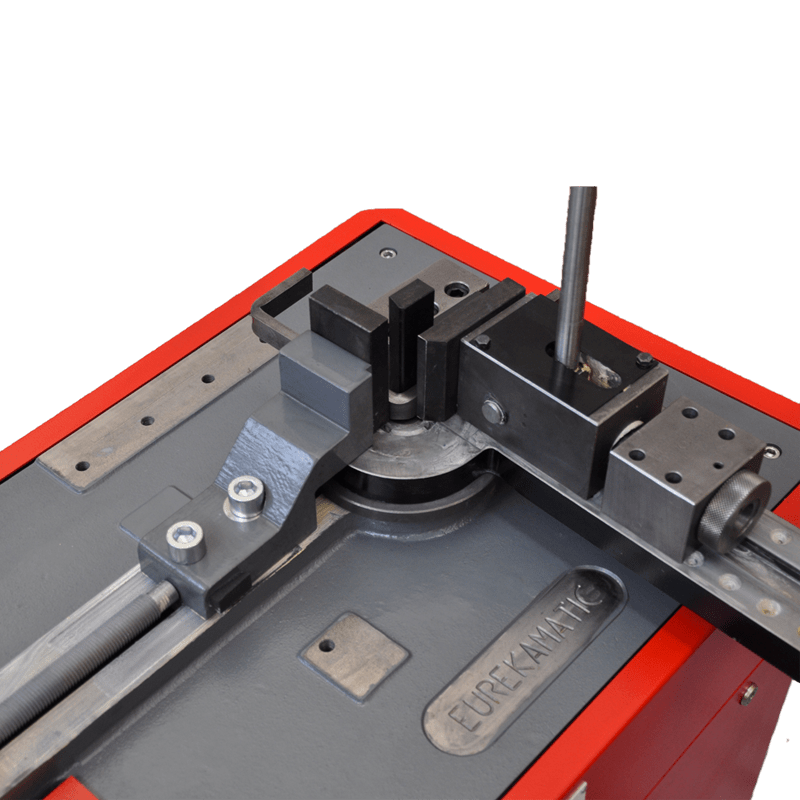

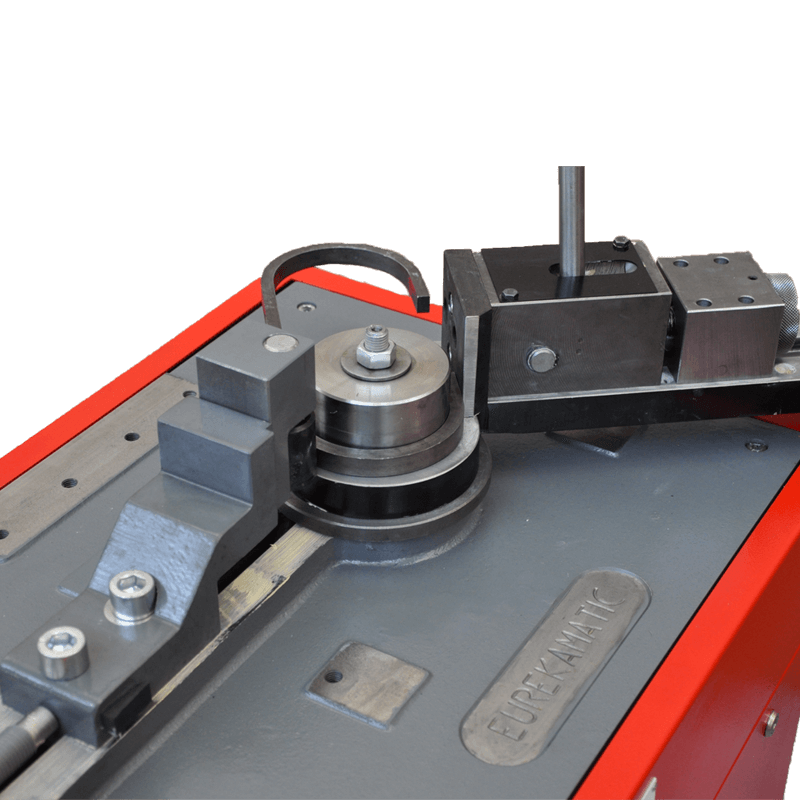

Tools

EUREKAMATIC AB-PF Angle bender

EUREKAMATIC AB-CF Circle-curve bender

EUREKAMATIC AB-CTA Tube & Pipe bender with/without mandrel

EUREKAMATIC CS Scroll-spiral bender

Maximum capacity (mm)

Maximum capacity for each model (mm)

|

MATERIAL |

AB-PF |

AB-CF |

AB-CTA |

CS |

|---|---|---|---|---|

|

Solid round |

Ø 25 |

Ø 25 |

|

Ø 12 |

|

Solid square |

22 |

22 |

|

12 |

|

Flat |

100 x 10 |

50 x 15 |

|

30 x 12 |

|

Pipe without mandrel |

|

|

Ø 40 x 2 |

|

|

Pipe with mandrel |

|

|

Ø 30 x 2 |

|

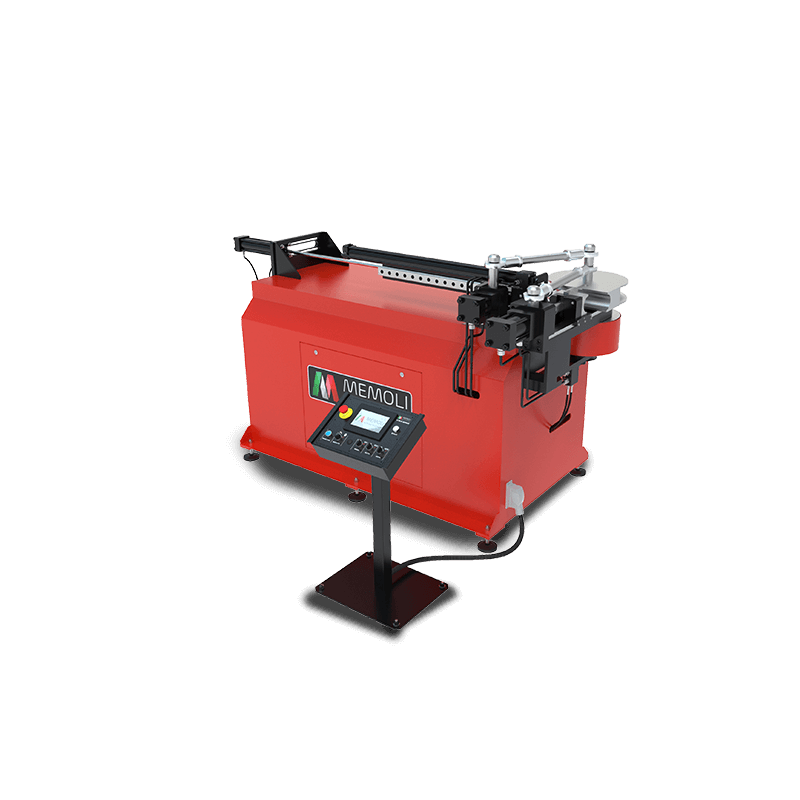

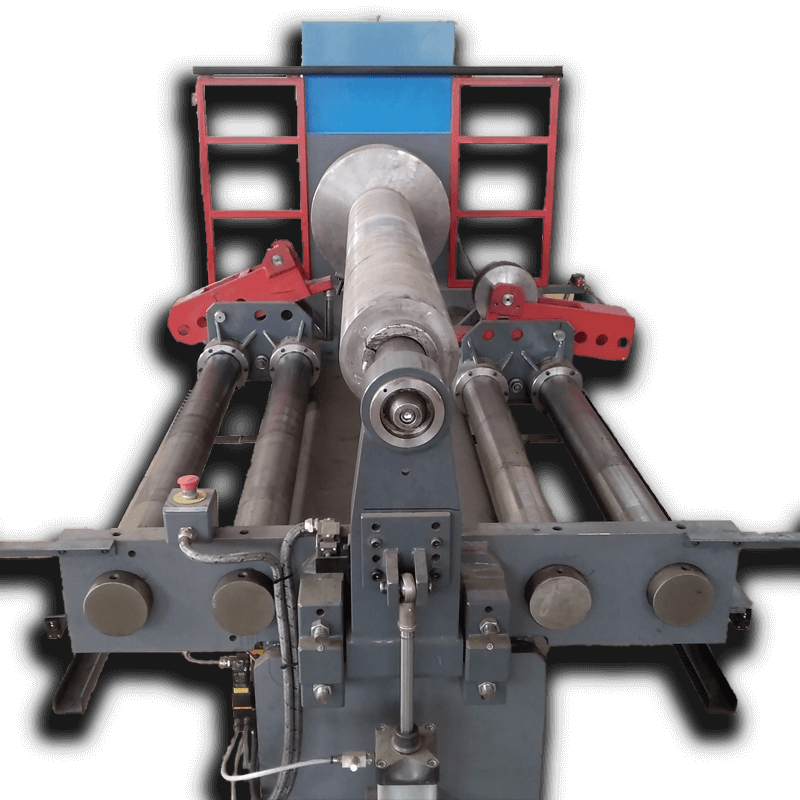

ETM ROTARY DRAW BENDERS

The ETM series is equipped with state of the art technologies meant to bend without mandrel tubes and profiles, and capable of bending both in right and left direction. It allows to bend tubes with a range diameter from 8 mm up to 168 mm and it can make curves over 180° with top finish quality for a minimum bending radius of 3 x the tube diameter.

Every ETM rotary draw bender is manufactured from single steel block and the tooling is machined from solid steel.

The system of counter dies is specifically designed to reduce mechanical effort and to make the bending operation faster than other brands tube bending machines of the same category, thus granting a very good finishing even when bending very thin wall thicknesses.Thanks to its new software technology called “Digital Bend Programming Touch Screen 2”, this machine is extremely easy to use: this software in fact was specifically studied for our machines and enables to select up to 49 programs each of them with a 8 stop sequences in the bending operation and to automatically adjust the material springiness (spring back). Moreover, it allows to save and store one’s projects as repeatable programs.

ROTARY DRAW BENDERS MAXIMUM CAPACITY (mm)

|

MATERIAL |

ETM 60 |

ETM 80 |

ETM 90 |

ETM 120 |

ETM 150 |

|---|---|---|---|---|---|

|

FE 430 |

60 x 4 |

76 x 6 |

90 x 6 |

114 x 8 |

168 x 7 |

|

Aluminum |

60 x 8 |

76 x 8 |

90 x 10 |

140 x 7 |

168 x 10 |

|

INOX AISI 304 |

60 x 3 |

76 x 4 |

90 x 4 |

114 x 6 |

168 x 5,5 |

|

Solid Bar FE 430 |

45 |

55 |

65 |

85 |

110 |

|

Square Tube FE |

50 x 3 |

60 x 4 |

80 x 4 |

110 x 5 |

140 x 6 |

Click on the the drop downs below for more information on each model

ETM 60 ROTARY DRAW BENDER

It’s a compact tube bender with high performances, equipped with state of the art technologies meant to bend with or without mandrel tubes and profiles, and capable of bending both in right and left direction using dedicated tooling. It allows to bend tubes with a range diameter from 8 mm up to 60 x 4 mm and it can make curves over 180° with top finish quality.

The rotary draw bender ETM 60 machine is manufactured from single steel block and the tooling is machined from solid steel. It can also have the option of fitting hydraulic vice and positioner.

The system of counter formers is specifically designed to reduce mechanical effort and to make the bending operation faster than other brands machines of the same category, thus granting a very good finishing even when bending very thin wall thicknesses.

Technical specifications

|

SPECIFICATION |

ETM 60 |

ETM 80 |

ETM 90 |

ETM 120 |

ETM 150 |

|---|---|---|---|---|---|

|

Motor power |

KW 2 | KW 2,2 | KW 2,2 | KW 7,5 | KW 12 |

|

Rotation speed * |

6 g/1’ * |

3,5 g/1’ * |

3 g/1’ * |

0-5 g/1’ * |

0,5 g/1' * |

|

Gears |

Oil-bath |

Oil-bath |

Oil-bath |

Oil-bath |

Oil-bath |

|

Weight |

210 kg |

560 kg |

800 kg |

1800 kg |

2500 kg |

|

Size |

600 x 500 x 950 h. |

1100 x 810 x 1200 h. |

1300 x 870 x 1250 h. |

1300 x 750 x 1250 h. |

1700 x 1400 x 1600 h. |

Maximum capacity (mm)

|

MATERIAL |

ETM 60 |

ETM 80 |

ETM 90 |

ETM 120 |

ETM 150 |

|---|---|---|---|---|---|

|

FE 430 |

60 x 4 |

76 x 6 |

90 x 6 |

114 x 8 |

168 x 7 |

|

Aluminum |

60 x 8 |

76 x 8 |

90 x 10 |

140 x 7 |

168 x 10 |

|

INOX AISI 304 |

60 x 3 |

76 x 4 |

90 x 4 |

114 x 6 |

168 x 5,5 |

|

Solid Bar FE 430 |

45 |

55 |

65 |

85 |

110 |

|

Square Tube FE |

50 x 3 |

60 x 4 |

80 x 4 |

110 x 5 |

140 x 6 |

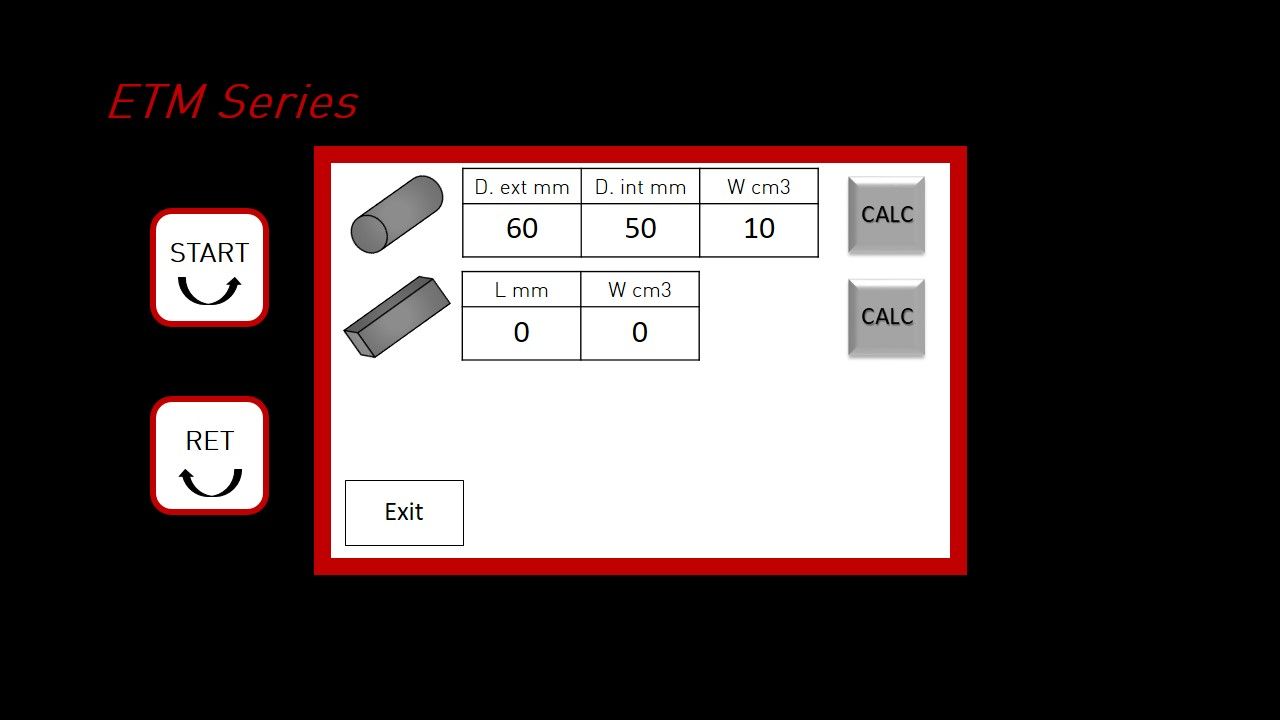

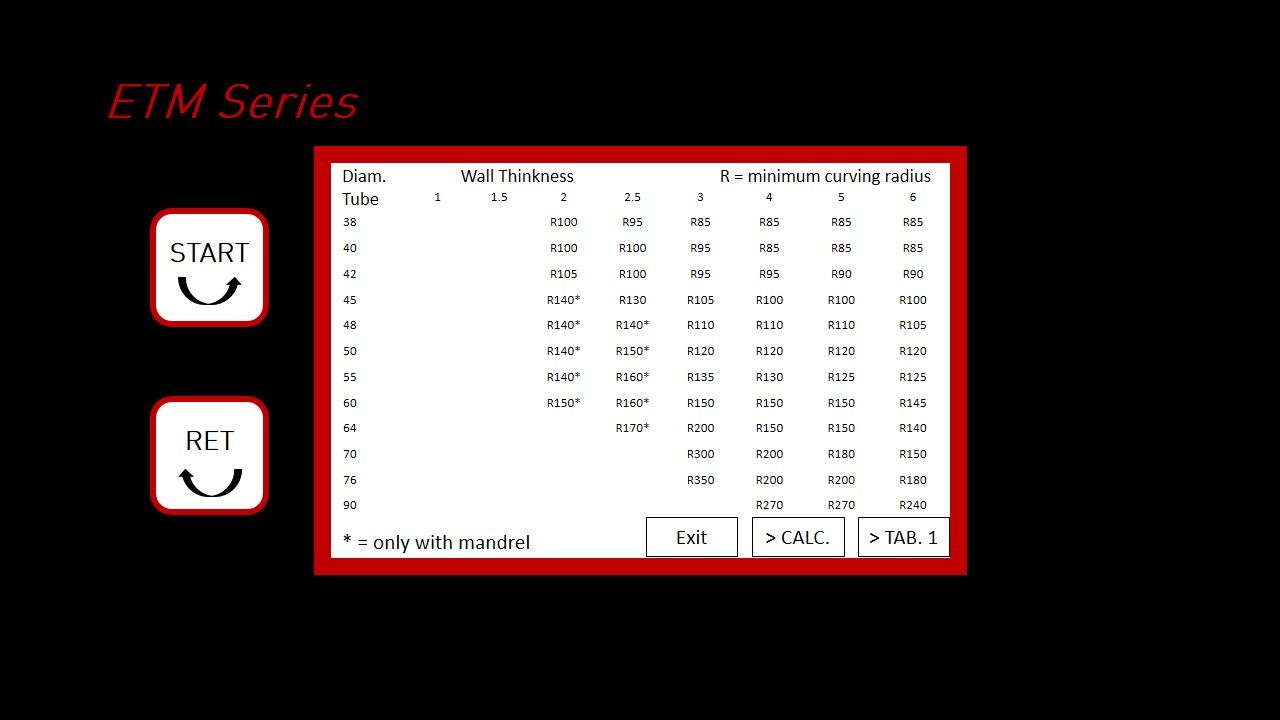

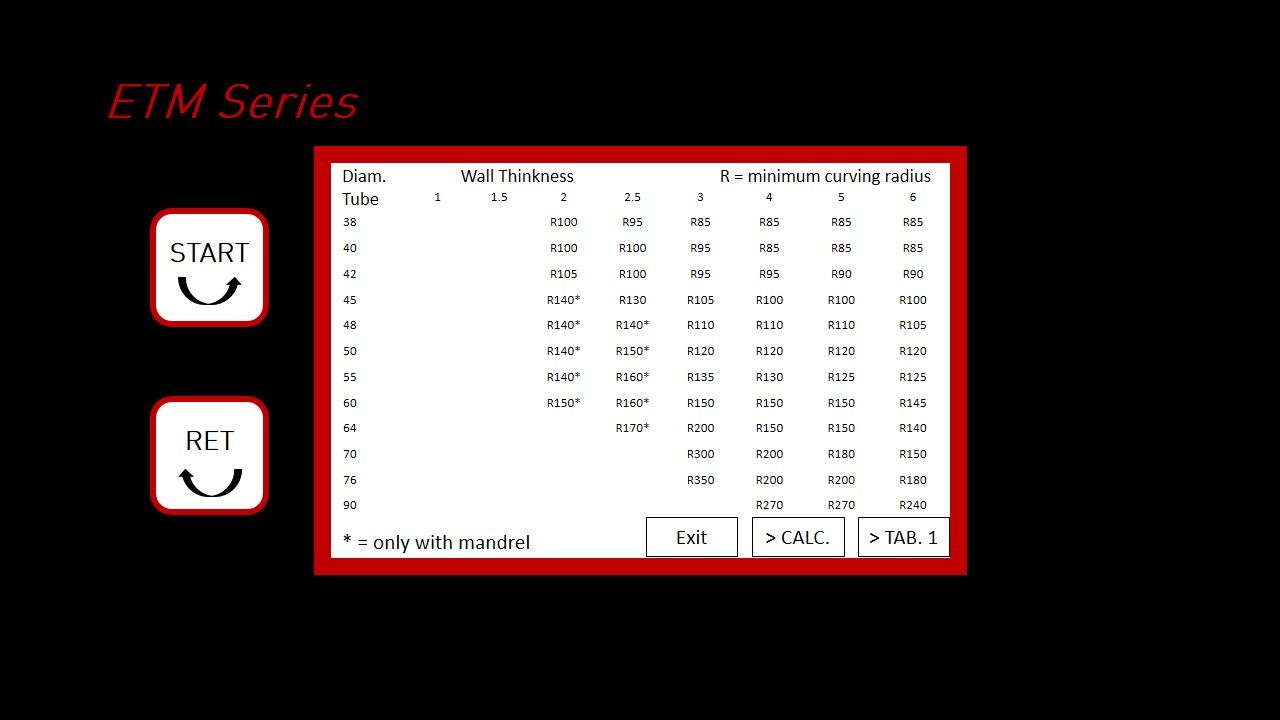

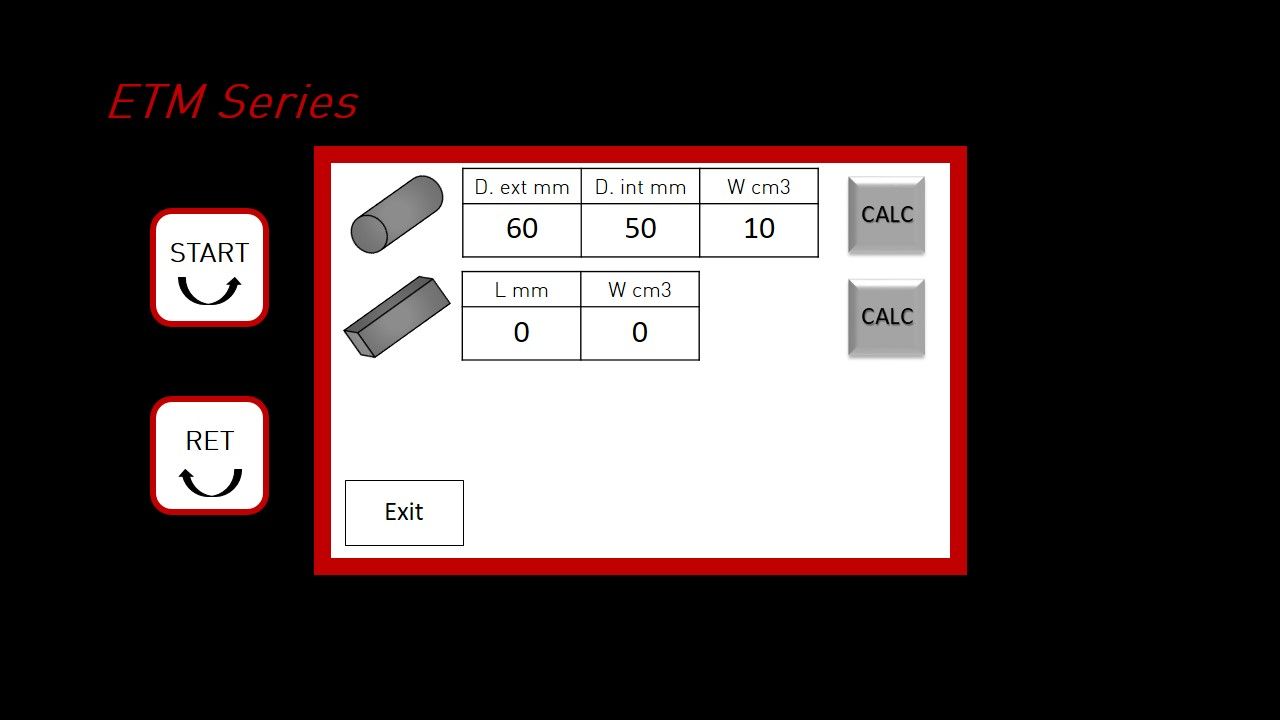

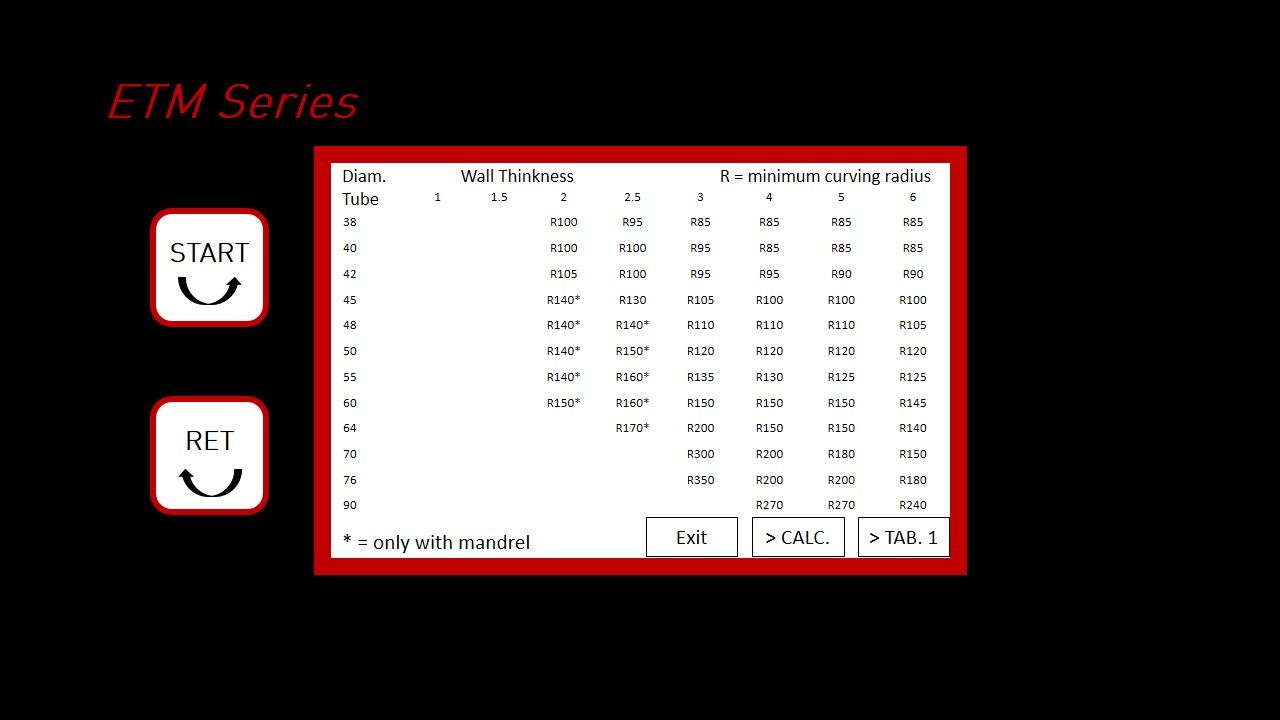

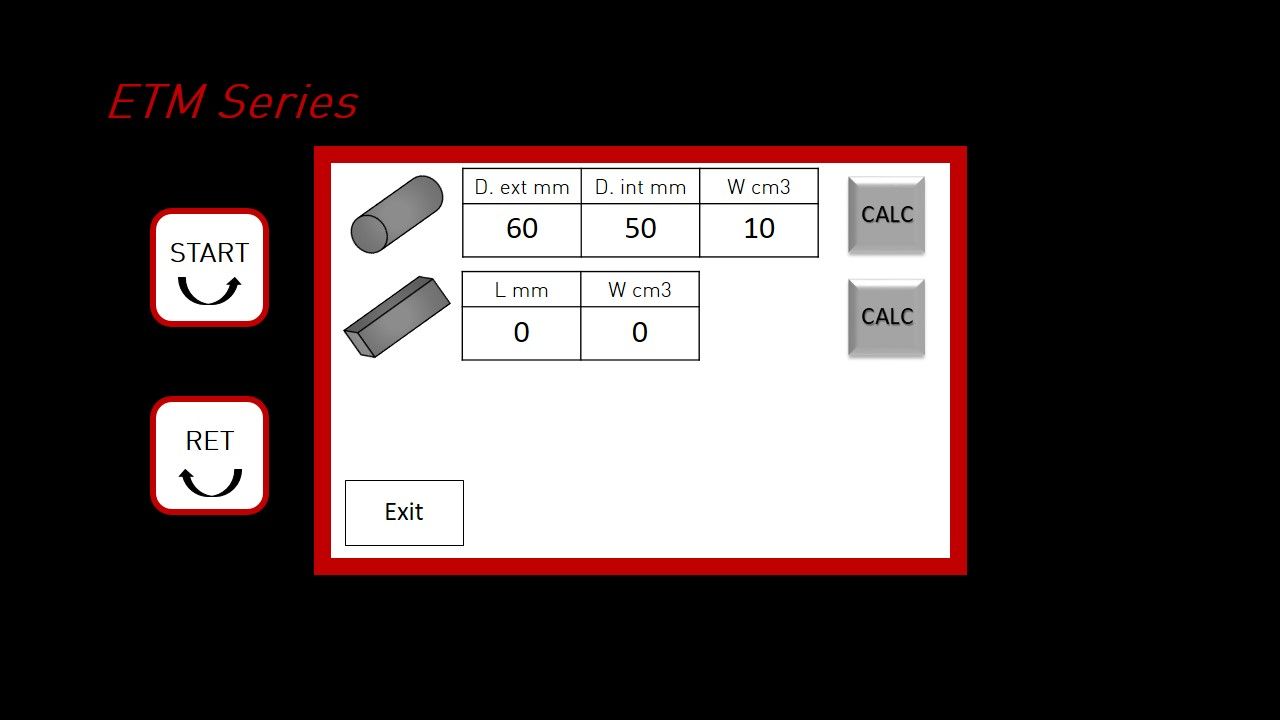

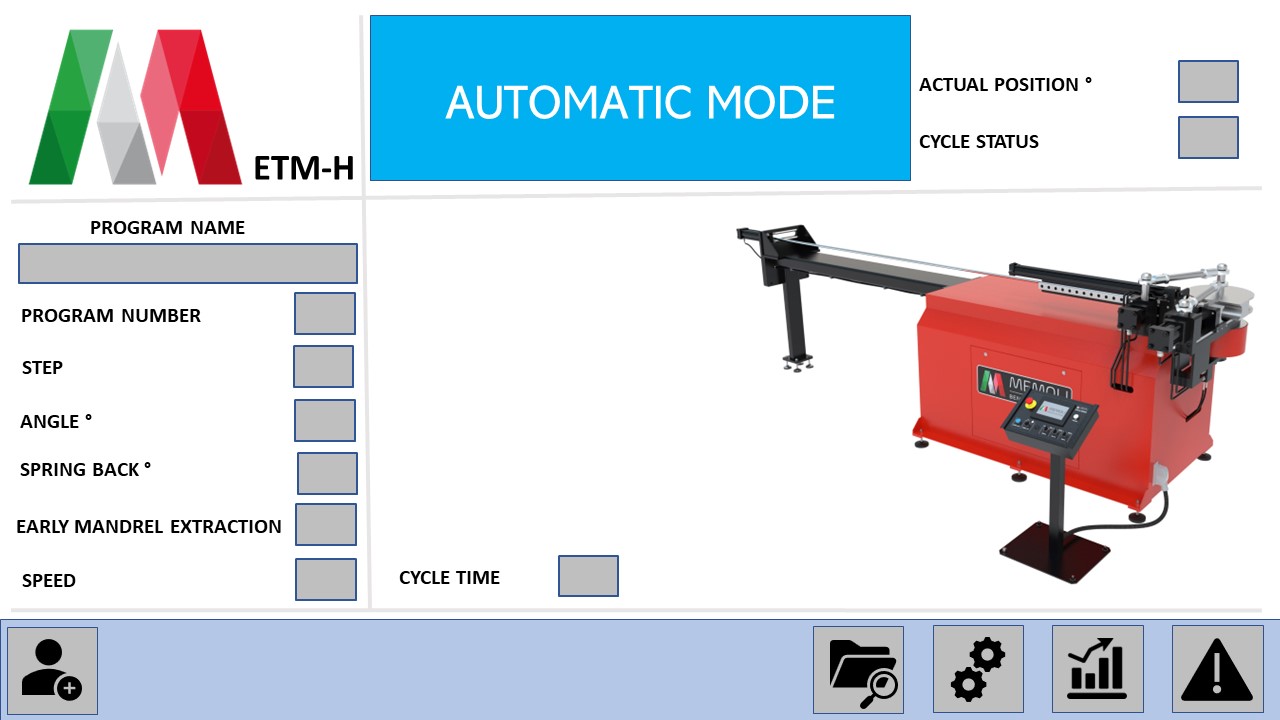

ETM SOFTWARE

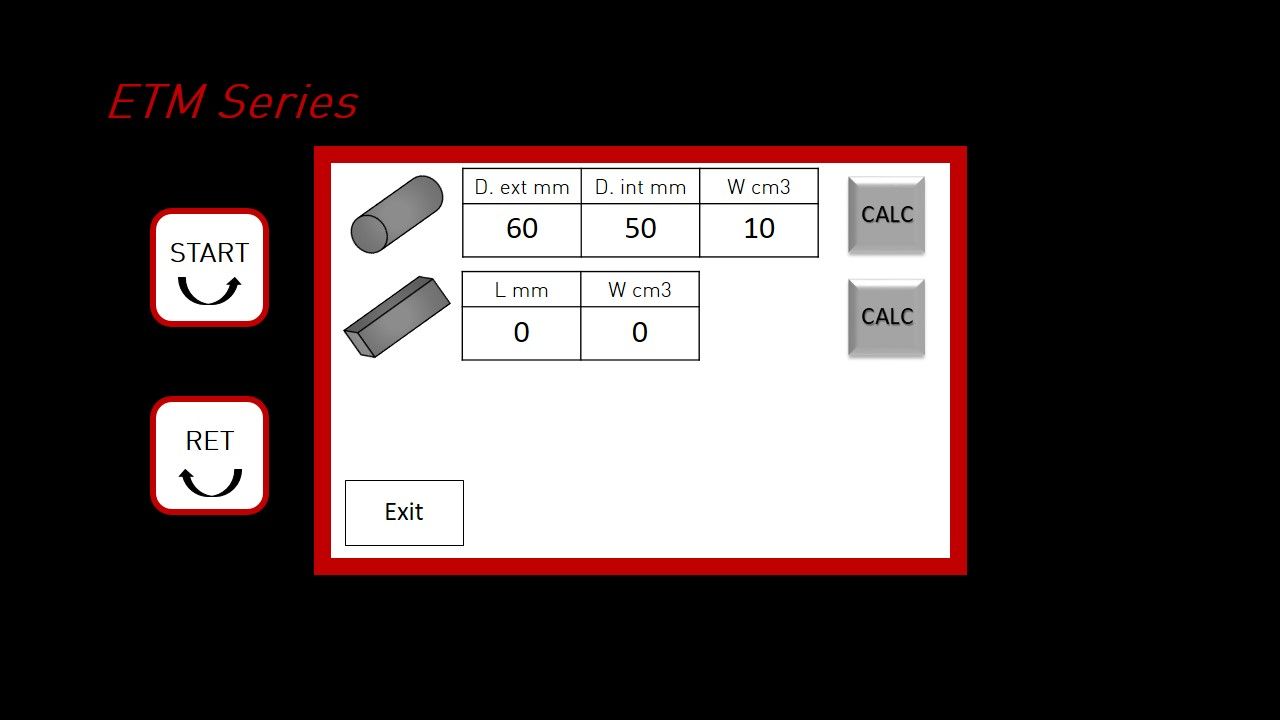

Every ETM series machine is supplied with the “Digital Bend Programming Touch Screen 2” special software, extremely easy to use due to the intuitive “Touch” screen.

Thanks to the latest generation technologies it is possible to access main features as:

-

Storage of 49 programs, each of them with a 8 stop sequences in the bending operation

-

Calculation of the machine maximum bending capacities with reference to the material size to be bent

-

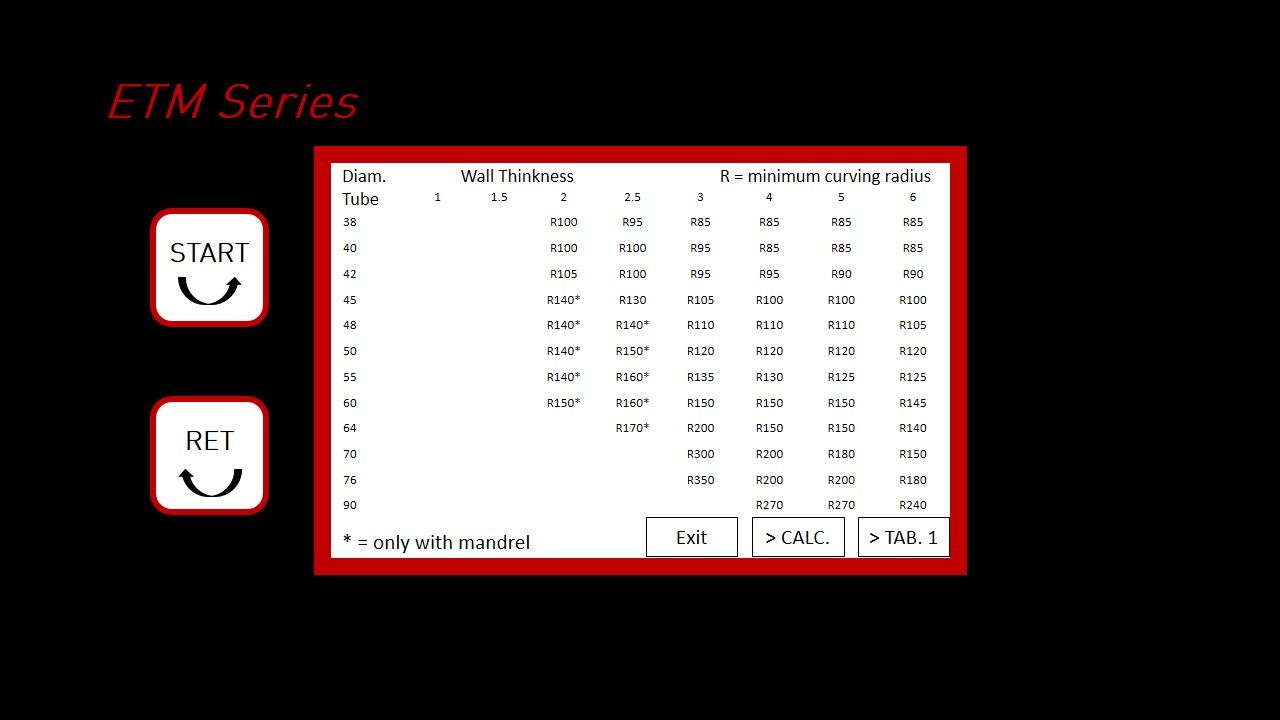

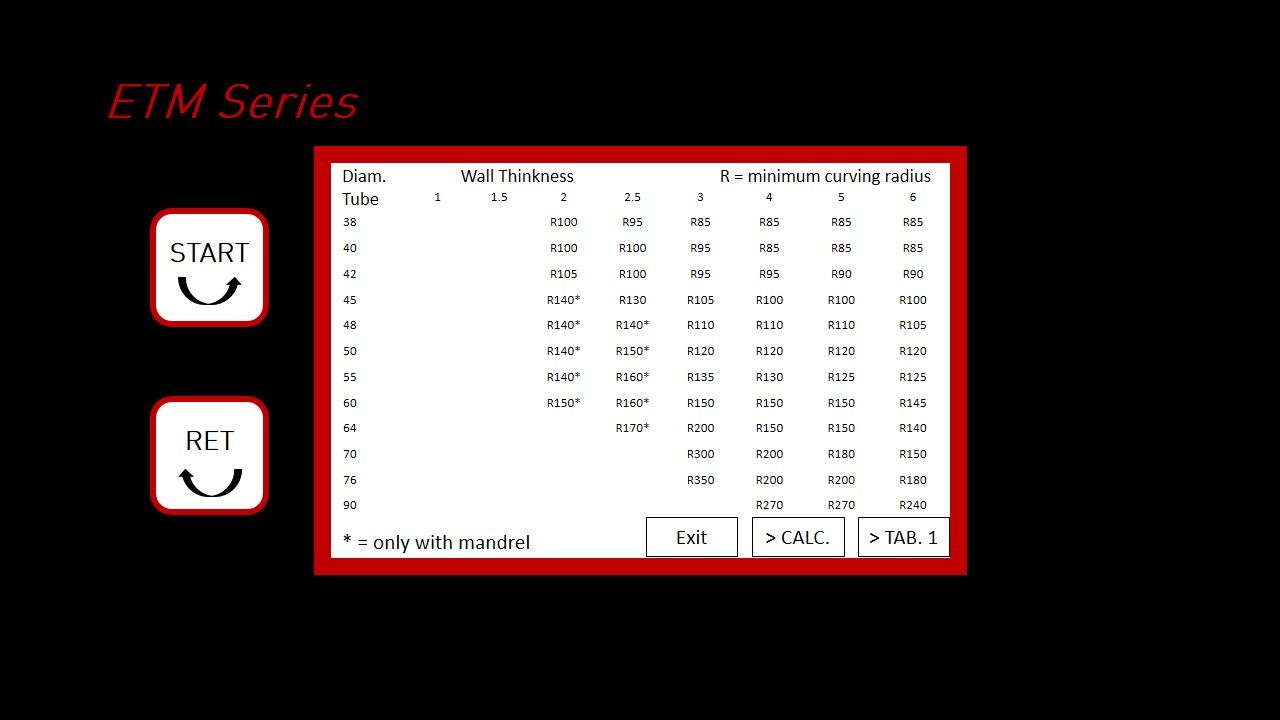

Graphic of the minimum bending radii

-

Setting of springiness material estimate (spring back)

-

Bend counter

-

Remote connection “Industry 4.0”

Some more functions:

- Working mode: either manual or automatic

- 100 MB hard disk

- Alarm diagnosis

- Maintenance notice

Watch the video

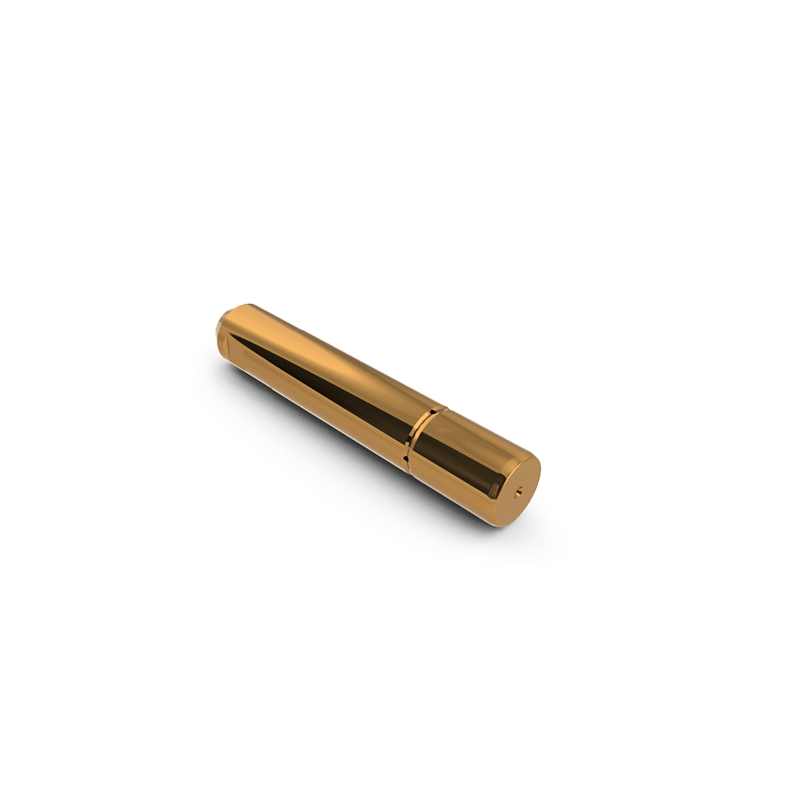

Tie Rod

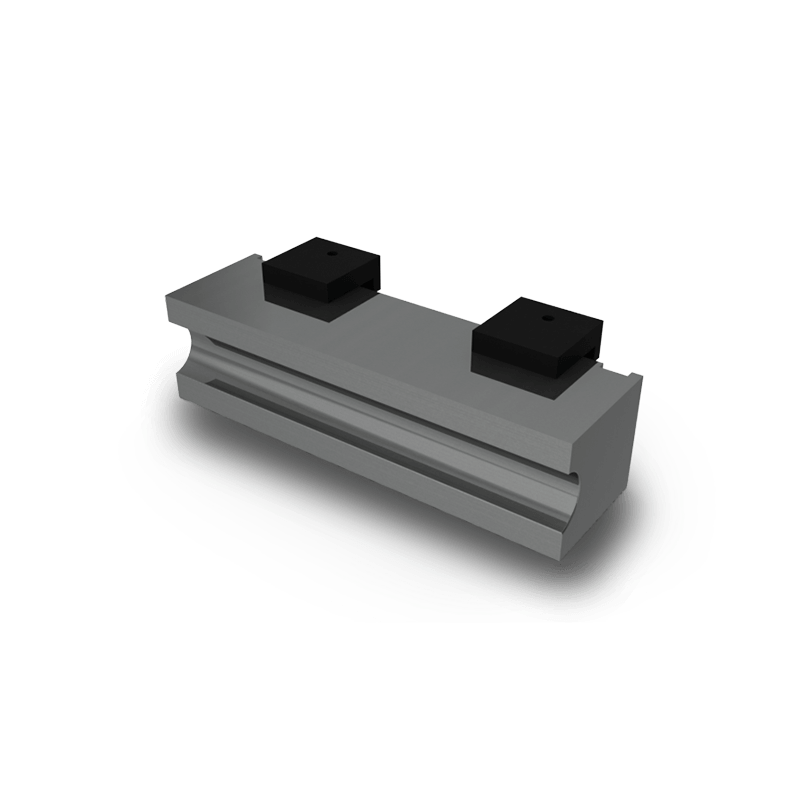

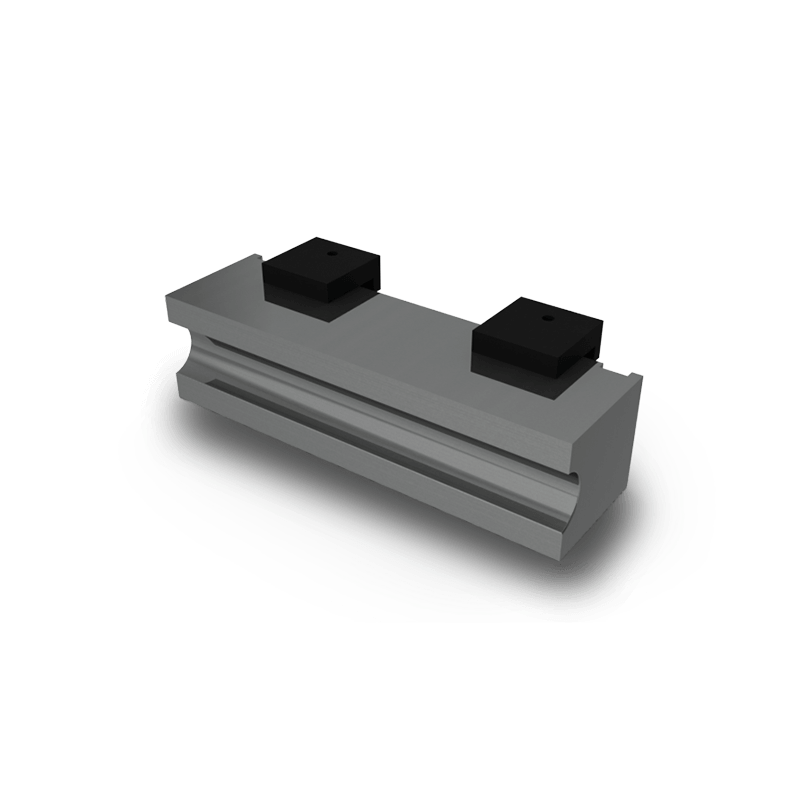

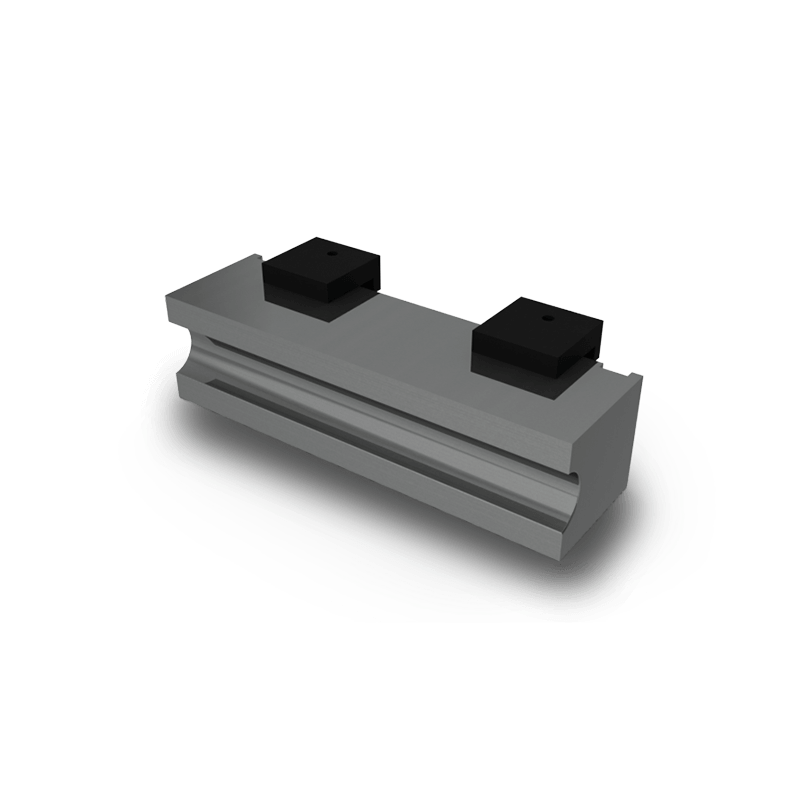

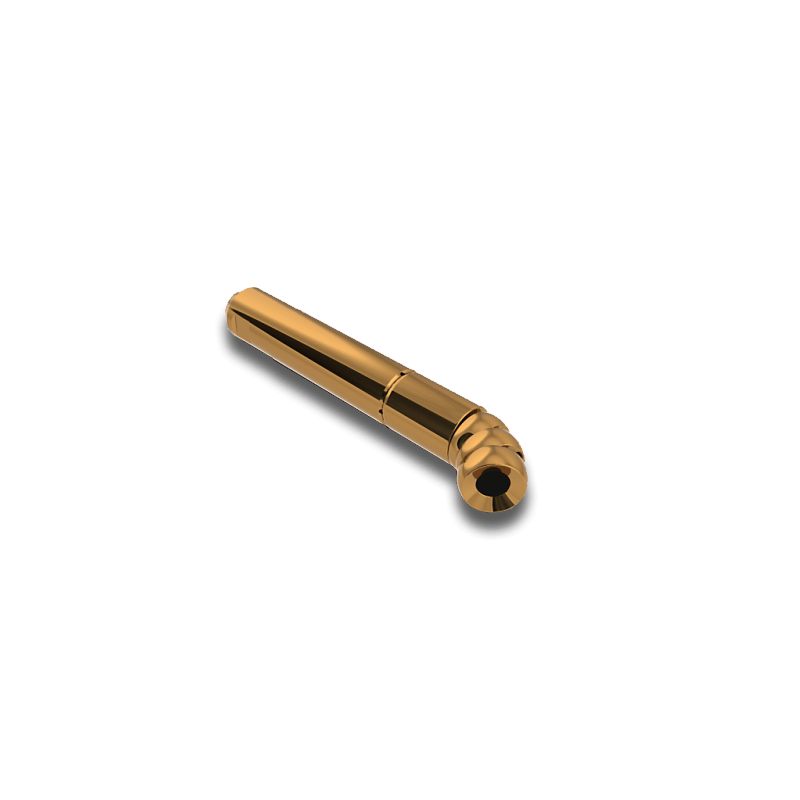

Slide counter mold

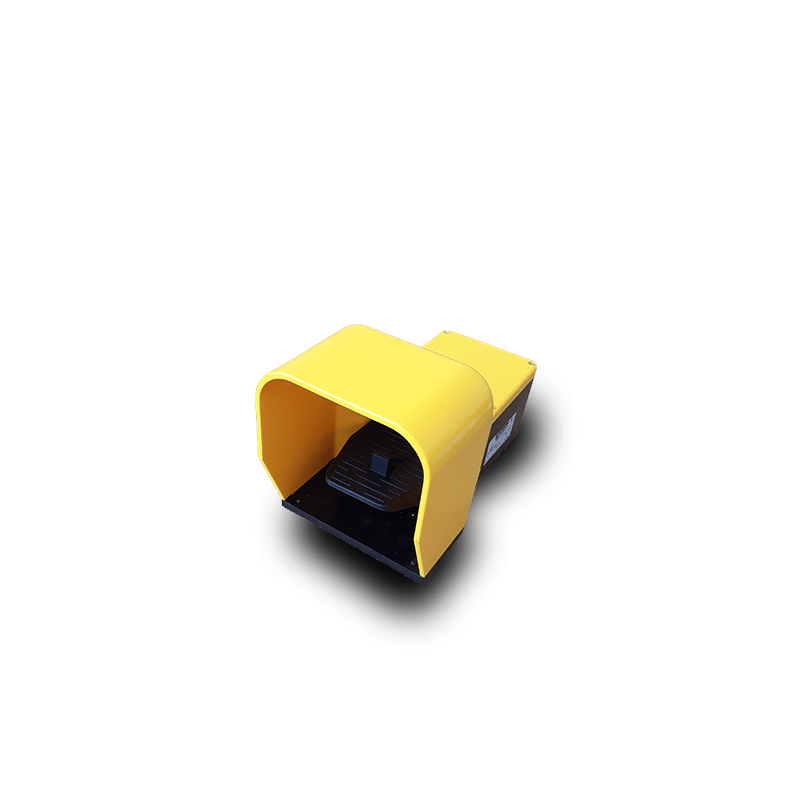

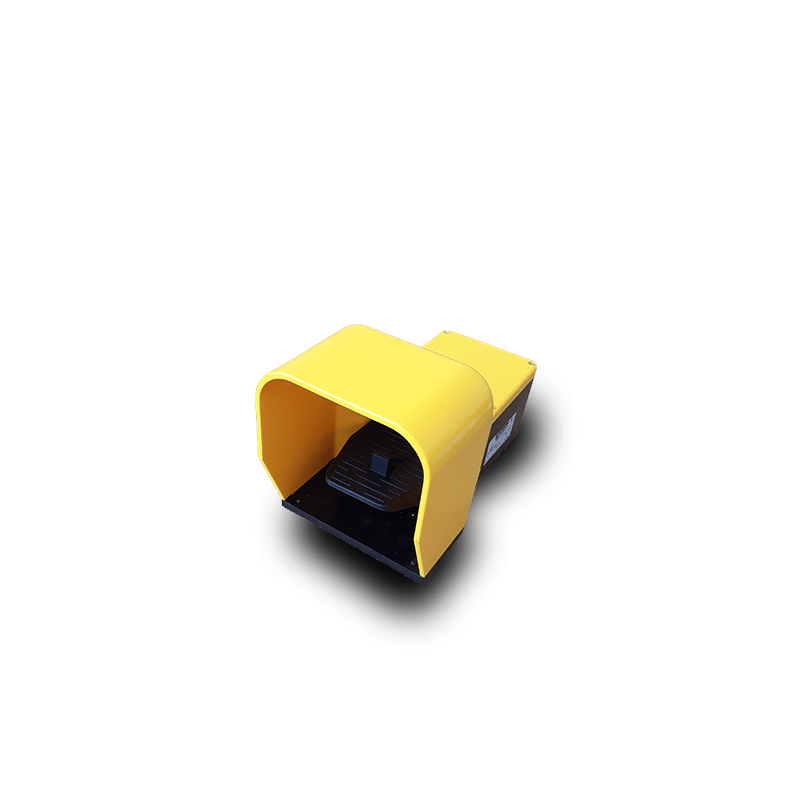

Foot control

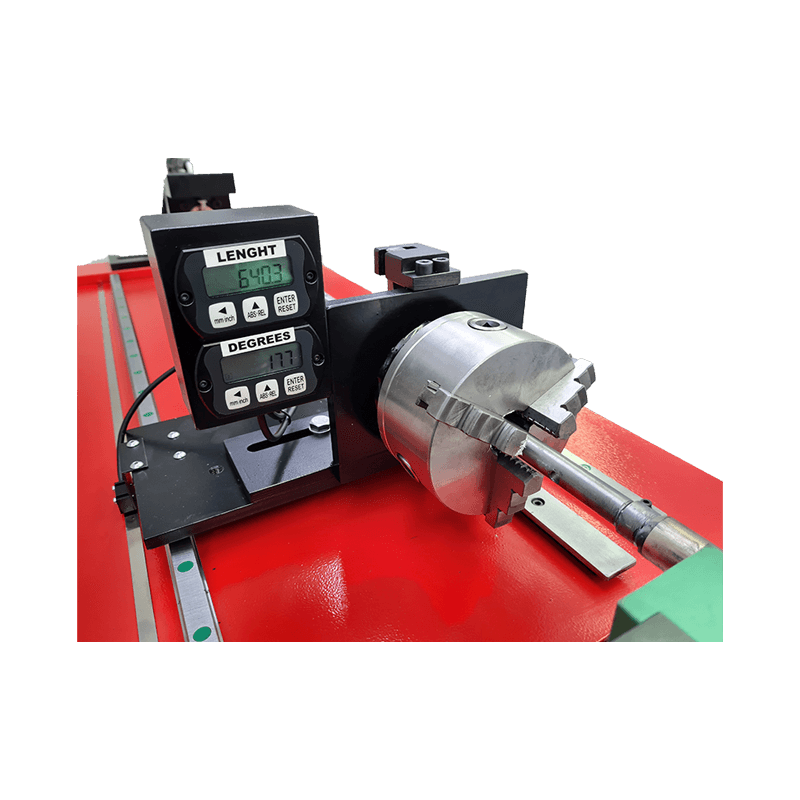

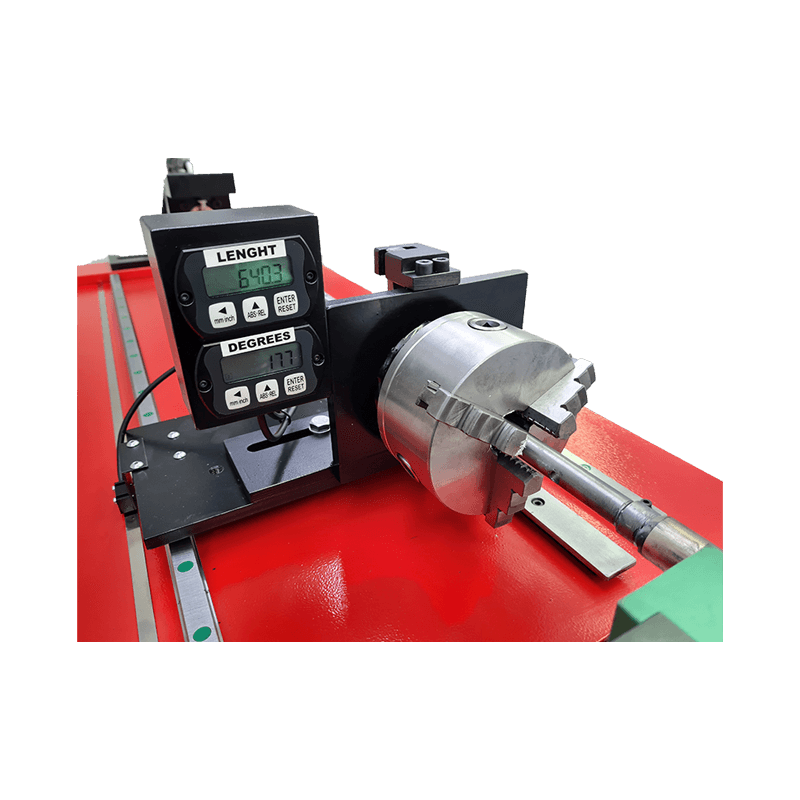

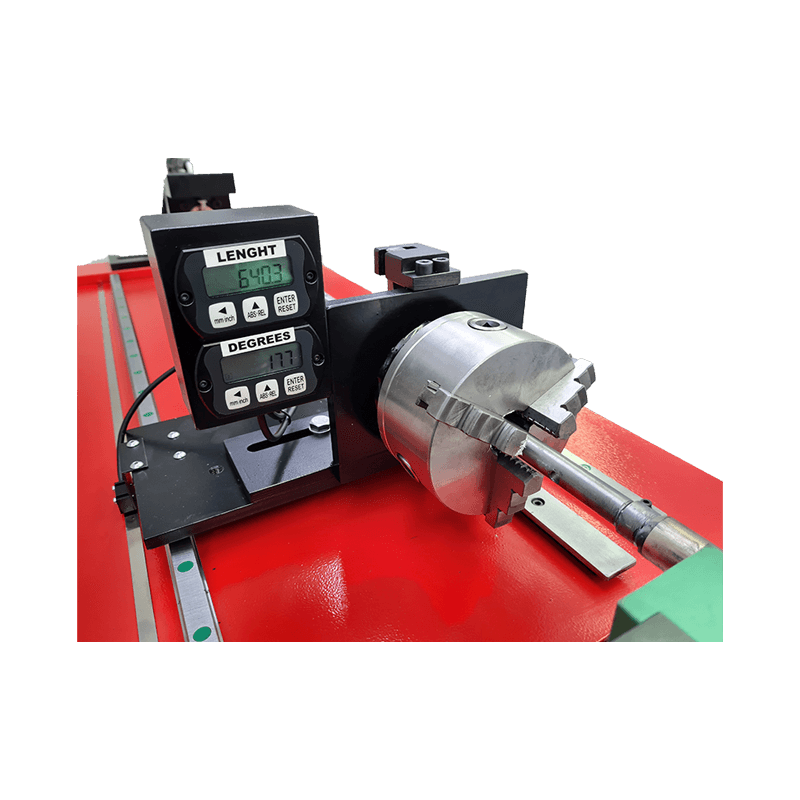

Digital display counter mold position

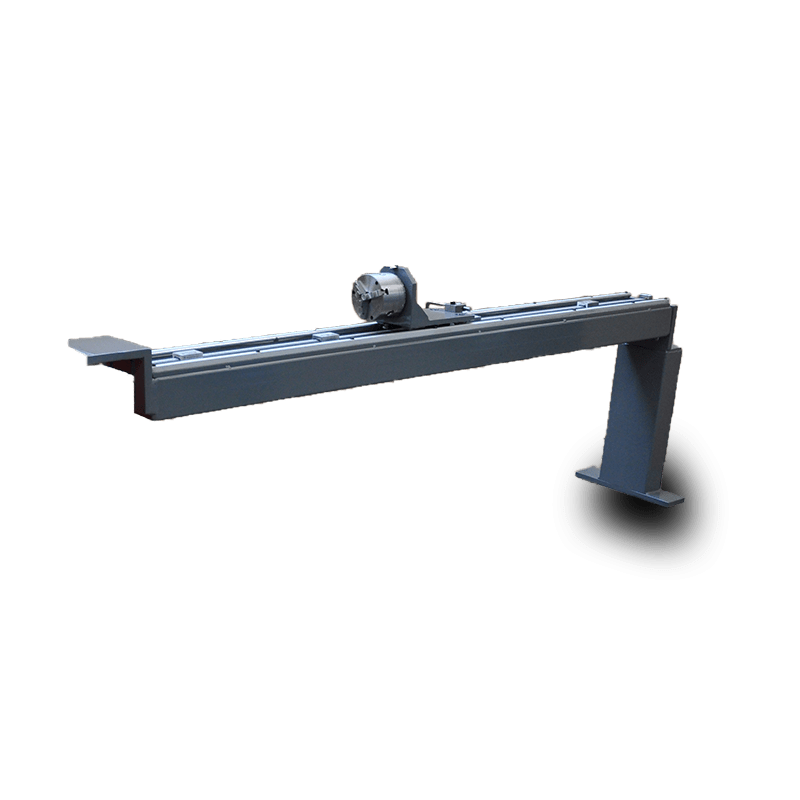

Positioner

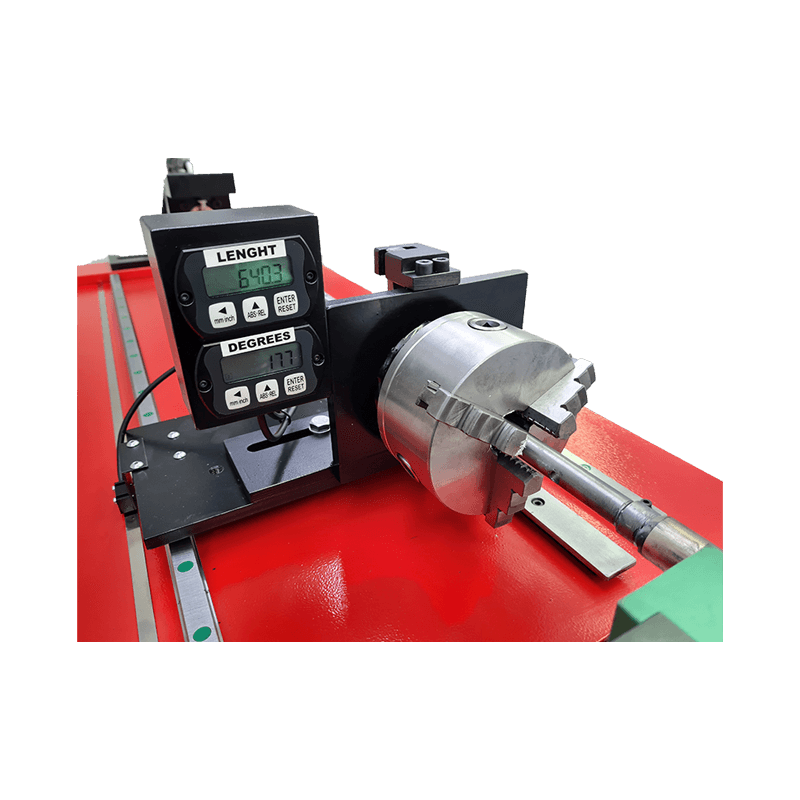

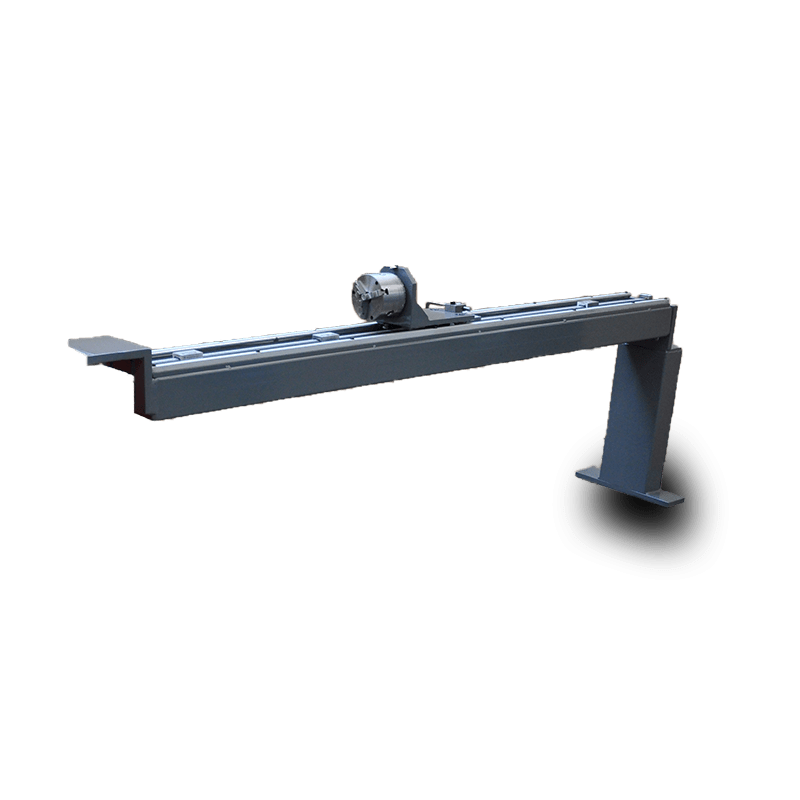

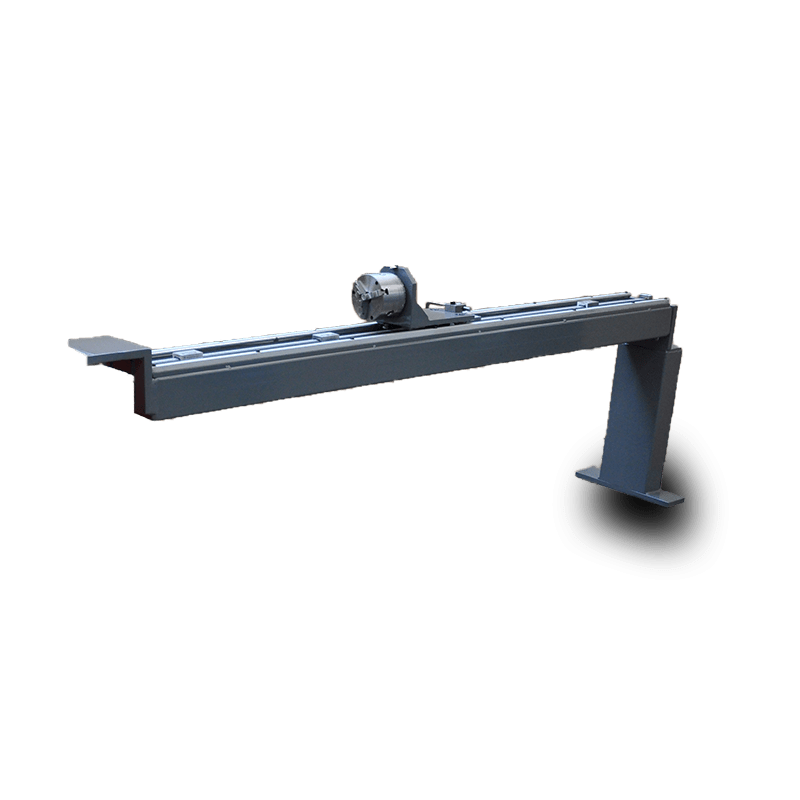

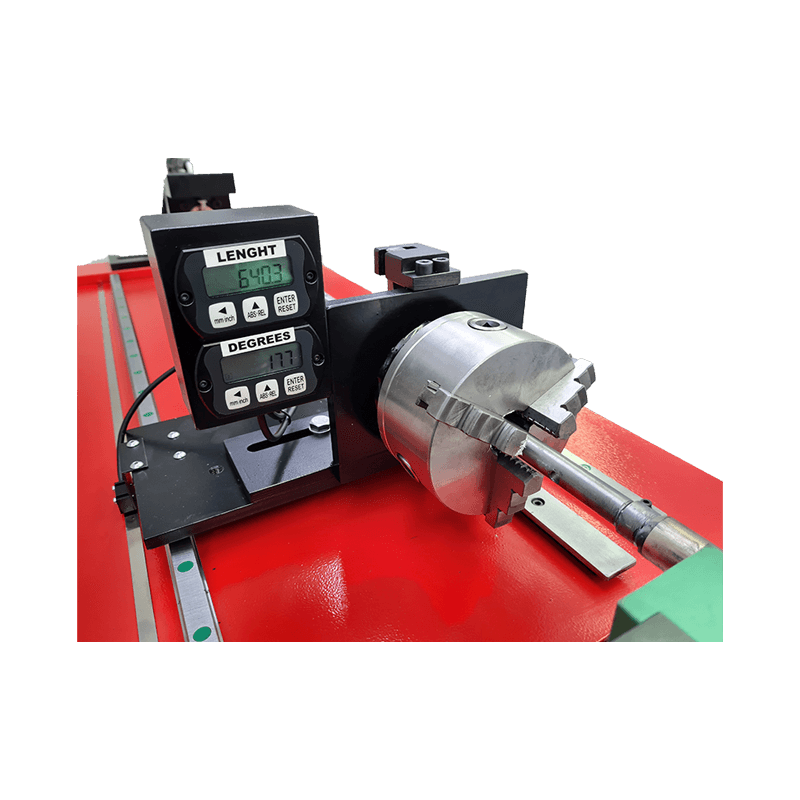

Length and rotation measuring system with digital display

ETM 80 ROTARY DRAW BENDER

New ETM 80 rotary draw bending machine, a powerful and precise no mandrel tube bending machine designed for all types of tubes and profiles.

A solid, high-performance machine, entirely “Made in Italy”, capable of bending large diameter tubes on both the right and left sides. The ETM 80 allows to bend tubes with a range diameter up to 76 x 6 mm, and can bend more than 180° with maximum finishing quality.

The machine is manufactured from a single piece of steel, with dies made from solid C45 steel.

The specially designed counter-dies system allows less mechanical effort and much faster machining than machines in the same category, guaranteeing excellent finishes even with the thinnest thicknesses.

Extremely easy and quick to use thanks to the “Digital Bend Programming Touch Screen 2”, software specially created for our machines, which can select as many as 49 programs with 8 bending angles each and with automatic correction of spring back. It also allows you to save your projects as repeatable programs.

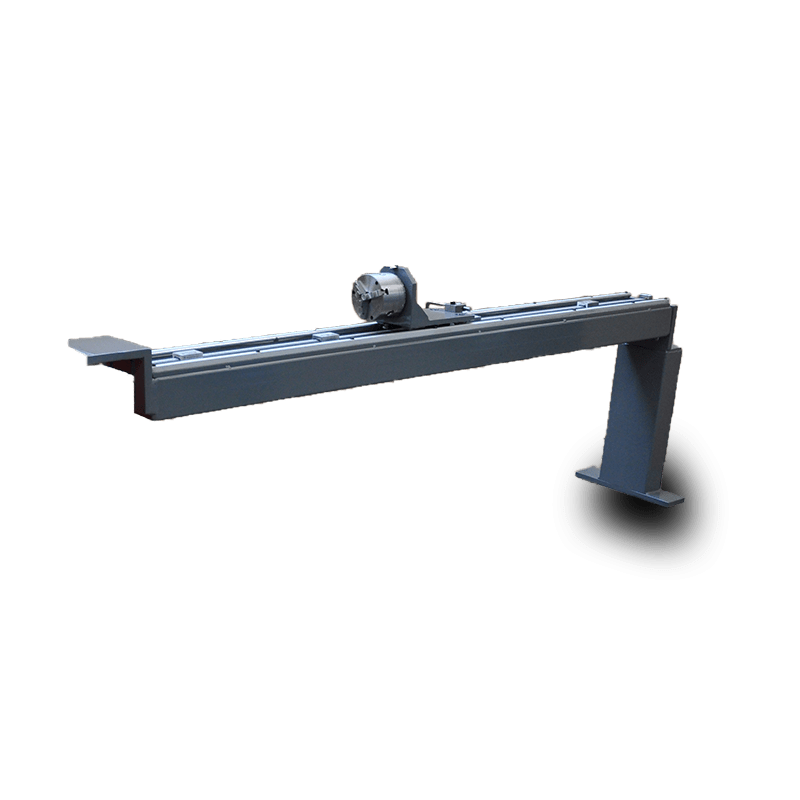

The ETM 80 can be equipped with a manual rotary positioning table. This table is available in various lengths for repeatable bends in a single piece of material. When the table is attached to the bender, it helps achieve very accurate bends on varying planes, as well as consistent measurements between bends.

Reliable and well-performing machine, it is perfect for various activities and fields like hydraulic, nautical and general plant construction engineering.

Technical specifications

|

SPECIFICATIONS |

ETM 60 |

ETM 80 |

ETM 90 | ETM 120 | ETM 150 |

|---|---|---|---|---|---|

|

Motor power |

KW 2 |

KW 2,2 |

KW 2,2 |

KW 7,5 |

KW 12 |

|

Rotation speed * |

6 g/1’ * |

3,5 g/1’ * |

3 g/1’ * |

0-5 g/1’ * |

0,5 g/1' * |

|

Gears |

Oil-bath |

Oil-bath |

Oil-bath |

Oil-bath |

Oil-bath |

|

Weight |

210 kg |

560 kg |

800 kg |

1800 kg |

2500 kg |

|

Size |

600 x 500 x 950 h. |

1100 x 810 x 1200 h. |

1300 x 870 x 1250 h. |

1300 x 750 x 1250 h. |

1700 x 1400 x 1600 h. |

Maximum capacity (mm)

|

MATERIAL |

ETM 60 |

ETM 80 |

ETM 90 |

ETM 120 |

ETM 150 |

|---|---|---|---|---|---|

|

FE 430 |

60 x 4 |

76 x 6 |

90 x 6 |

114 x 8 |

168 x 7 |

|

Aluminum |

60 x 8 |

76 x 8 |

90 x 10 |

140 x 7 |

168 x 10 |

|

INOX AISI 304 |

60 x 3 |

76 x 4 |

90 x 4 |

114 x 6 |

168 x 5,5 |

|

Solid Bar FE 430 |

45 |

55 |

65 |

85 |

110 |

|

Square Tube FE |

50 x 3 |

60 x 4 |

80 x 4 |

110 x 5 |

140 x 6 |

ETM ROTARY DRAW BENDER SOFTWARE

Every ETM series machine is supplied with the “Digital Bend Programming Touch Screen 2” special software, extremely easy to use due to the intuitive “Touch” screen.

Thanks to the latest generation technologies it is possible to access main features as:

-

Storage of 49 programs, each of them with a 8-stop sequences in the bending operation

-

Calculation of the machine maximum bending capacities with reference to the material size to be bent

-

Graphic of the minimum bending radii

-

Setting of springiness material estimate (spring back)

-

Bend counter

-

Remote connection “Industry 4.0”

Additional Functions:

-

Working mode: either manual or automatic

-

100 MB hard disk

-

Alarm diagnosis

-

Maintenance notice

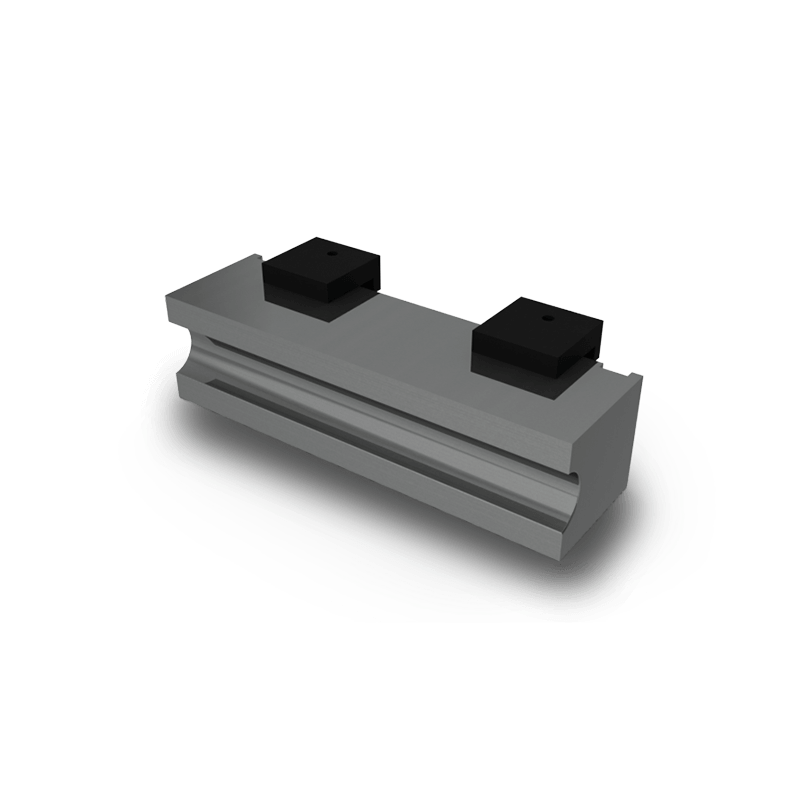

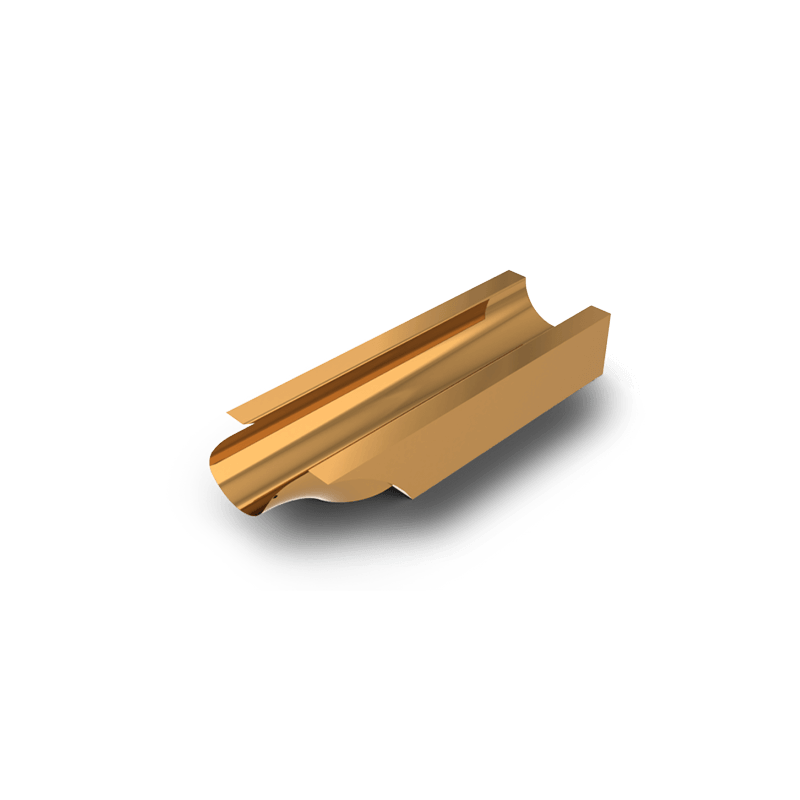

Slide counter mold

Foot control

Digital display counter mold position

Positioner

Length and rotation measuring system with digital display

ETM 90 ROTARY DRAW BENDER

Our tube bender ETM 90 is equipped with state of the art technologies meant to bend with or without mandrel tubes and profiles, and capable of bending both in right and left direction using dedicated tooling. It allows to bend tubes with a range diameter up to 90 x 6 mm and it can make curves over 180° with top finish quality.

This machine is manufactured from single steel block and the tooling is machined from solid steel. It can also have the option of fitting hydraulic vice and positioner.

The system of counter formers is specifically designed to reduce mechanical effort and to make the bending operation faster than other brands machines of the same category, thus granting a very good finishing even when bending very thin wall thicknesses.

Technical specifications

|

SPECIFICATION |

ETM 60 | ETM 80 |

ETM 90 |

ETM 120 | ETM 150 |

|---|---|---|---|---|---|

|

Motor power |

KW 2 |

KW 2,2 |

KW 2,2 |

KW 7,5 |

KW 12 |

|

Rotation speed * |

6 g/1’ * |

3,5 g/1’ * |

3 g/1’ * |

0-5 g/1’ * |

0,5 g/1' * |

|

Gears |

Oil-bath |

Oil-bath |

Oil-bath |

Oil-bath |

Oil-bath |

|

Weight |

210 kg |

560 kg |

800 kg |

1800 kg |

2500 kg |

|

Size |

600 x 500 x 950 h. |

1100 x 810 x 1200 h. |

1300 x 870 x 1250 h. |

1300 x 750 x 1250 h. |

1700 x 1400 x 1600 h. |

Maximum capacity (mm)

|

MATERIAL |

ETM 60 | ETM 80 |

ETM 90 |

ETM 120 | ETM 150 |

|---|---|---|---|---|---|

|

FE 430 |

60 x 4 |

76 x 6 |

90 x 6 |

114 x 8 |

168 x 7 |

|

Aluminum |

60 x 8 |

76 x 8 |

90 x 10 |

140 x 7 |

168 x 10 |

|

INOX AISI 304 |

60 x 3 |

76 x 4 |

90 x 4 |

114 x 6 |

168 x 5,5 |

|

Solid Bar FE 430 |

45 |

55 |

65 |

85 |

110 |

|

Square Tube FE |

50 x 3 |

60 x 4 |

80 x 4 |

110 x 5 |

140 x 6 |

ETM ROTARY DRAW BENDER SOFTWARE

Every ETM series machine is supplied with the “Digital Bend Programming Touch Screen 2” special software, extremely easy to use due to the intuitive Touch screen.

Thanks to the latest generation technologies it is possible to access main features as:

-

Storage of 49 programs, each of them with a 8 stop sequences in the bending operation

-

Calculation of the machine maximum bending capacities with reference to the material size to be bent

-

Graphic of the minimum bending radii

-

Setting of springiness material estimate

(spring back)

-

Bend counter

-

Remote connection “Industry 4.0”

Additional Functions:

-

Working mode: either manual or automatic

-

100 MB hard disk

-

Alarm diagnosis

-

Maintenance notice

Watch the video

Tie Rod

Slide counter mold

Foot control

Digital display counter mold position

Positioner

Length and rotation measuring system with digital display

ETM 120 ROTARY DRAW BENDER

Our rotary draw bender ETM 120 machine is equipped with state of the art technologies meant to bend with or without mandrel tubes and profiles, and capable of bending both in right and left direction using dedicated tooling. It allows to bend tubes with a range diameter up to 114 x 8 mm and it can make curves over 180° with top finish quality.

This machine is manufactured from single steel block and the tools are machined from solid steel. It can also have the option of fitting hydraulic vice and positioner.

The system of counter formers is specifically designed to reduce mechanical effort and to make the bending operation faster than other brands machines of the same category, thus granting a very good finishing even when bending very thin wall thicknesses.

Technical specifications

|

SPECIFICATION |

ETM 60 | ETM 80 | ETM 90 |

ETM 120 |

ETM 150 |

|---|---|---|---|---|---|

|

Motor power |

KW 2 |

KW 2,2 |

KW 2,2 |

KW 7,5 |

KW 12 |

|

Rotation speed * |

6 g/1’ * |

3,5 g/1’ * |

3 g/1’ * |

0-5 g/1’ * |

0,5 g/1' * |

|

Gears |

Oil-bath |

Oil-bath |

Oil-bath |

Oil-bath |

Oil-bath |

|

Weight |

210 kg |

560 kg |

800 kg |

1800 kg |

2500 kg |

|

Size |

600 x 500 x 950 h. |

1100 x 810 x 1200 h. |

1300 x 870 x 1250 h. |

1300 x 750 x 1250 h. |

1700 x 1400 x 1600 h. |

Maximum capacity (mm)

|

MATERIAL |

ETM 60 |

ETM 80 |

ETM 90 |

ETM 120 |

ETM 150 |

|---|---|---|---|---|---|

|

FE 430 |

60 x 4 |

76 x 6 |

90 x 6 |

114 x 8 |

168 x 7 |

|

Aluminum |

60 x 8 |

76 x 8 |

90 x 10 |

140 x 7 |

168 x 10 |

|

INOX AISI 304 |

60 x 3 |

76 x 4 |

90 x 4 |

114 x 6 |

168 x 5,5 |

|

Solid Bar FE 430 |

45 |

55 |

65 |

85 |

110 |

|

Square Tube FE |

50 x 3 |

60 x 4 |

80 x 4 |

110 x 5 |

140 x 6 |

ETM ROTARY DRAW BENDER SOFTWARE

Every ETM series machine is supplied with the “Digital Bend Programming Touch Screen 2” special software, extremely easy to use due to the intuitive “Touch” screen.

Thanks to the latest generation technologies it is possible to access main features as:

- Storage of 49 programs, each of them with a 8-stop sequences in the bending operation

- Calculation of the machine maximum bending capacities with reference to the material size to be bent

- Graphic of the minimum bending radii

- Setting of springiness material estimate (spring back)

- Bend counter

- Remote connection “Industry 4.0”

Additional Functions:

-

Working mode: either manual or automatic

-

100 MB hard disk

-

Alarm diagnosis

-

Maintenance notice

Tie Rod

Slide counter mold

Foot control

Digital display counter mold position

Positioner

Length and rotation measuring system

Mandrel Tube Benders

THE RANGE OF MEMOLI TUBE BENDING MACHINES WITH MANDREL CONSISTS OF 3 TYPES OF TUBE BENDING MACHINES:

-

ETM with MANDREL: ETM tube bending machines with fixed mandrel are perfect for the machining of tubes of small wall thickness and profiles: a compact, cheap and high-performance solution that guarantees exceptional repeatability. Our ETM tube bending machines with mandrel allow the machining of tubes up to 90 mm diameter and are able to bend with high-level finish qualityh, with a minimum radius of 2 x tube Ø.

-

ETM-H: in semi-automatic bending machines of the ETM-H series, the bending function is performed automatically, while the feeding and rotation of the tube between the bends must be performed manually. When machining tubes with multiple bends, the positioner will greatly facilitate the work, as this device allows the exact fixing of the length of the tube and the rotation position between the bends. Our ETM-H semi-automatic tube bending machines can bend tubes with a diameter up to 80 mm diameter with maximum quality of finishing, with a minimum bending radius of 1 x the tube Ø.

-

ACH: the tube bending machines of the ACH series are fully automatic bending machines with CNC 3 axes: bending (Y axis), advancement (X axis) and rotation (Z axis).

Click on the the drop downs below for more information on each model

ETM Electrical Tube Bending Machines with Mandrel

The ETM range of tube bending machines with mandrel is perfect for the machining of tubes of small wall thickness without deformation of the bent tube: a compact, high performance and cheap solution. Our fixed mandrel ETM tube benders allow the machining of tubes up to 90 mm diameter and are able to bend with high-level finish quality.

Extremely easy and fast to use thanks to the “Digital Bend Programming Touch Screen 2”, the software specially created for our machines is able to select as many as 49 programs with 8 bending angles each and with automatic correction of spring back. In addition, our software allows you to store your realized projects as repeatable programs.

Maximum capacity (mm)

|

MATERIAL |

ETM 60 |

ETM 80 |

ETM 90 |

|---|---|---|---|

|

FE 37 |

50 x 3 |

60 x 3 |

80 x 3 |

|

Aluminum |

60 x 2 |

76 x 3 |

90 x 4 |

|

INOX AISI 304 |

50 x 2 |

60 x 2 |

76 x 4 |

|

SQUARE PIPE |

40 x 3 |

60 x 3 |

70 x 3 |

GENERAL FEATURES

• Carbon steel frame

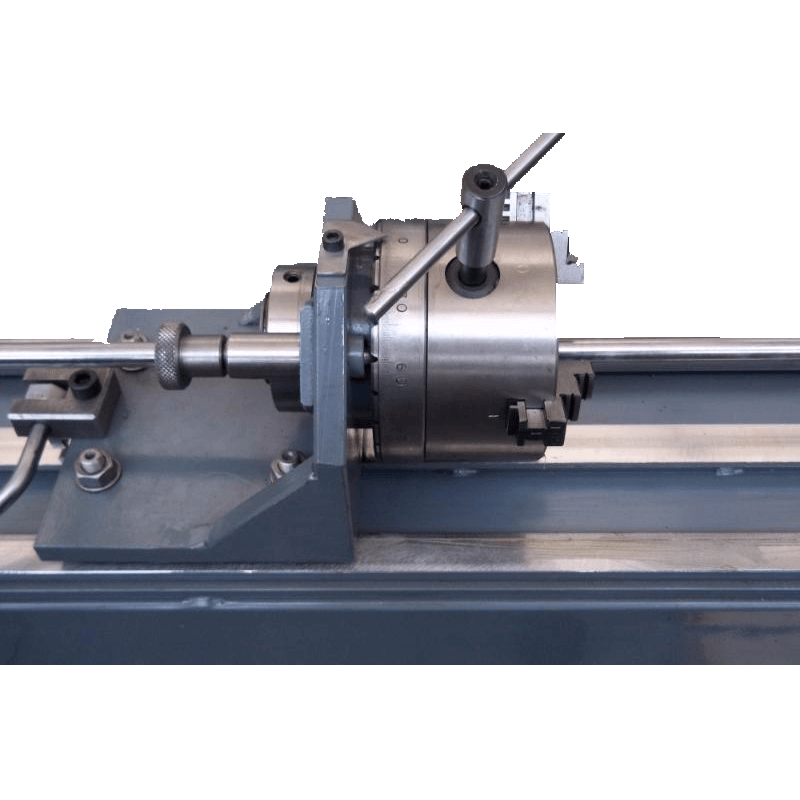

• C45 molds, machined from solid – with (optional) hardening process

• Fixed mandrel position

• Eccentric clamp die

• Eccentric pressure die

• Compact machine

• Variable bending speed

• Positioning device for tube length and rotation, incl. 3-jaw spindle (optional)

• Useful tube length 1.5; 2.5; 4.5; 6 m.

Watch The Video

ETM TUBE BENDER SOFTWARE

Every ETM series machine is supplied with the “Digital Bend Programming Touch Screen 2” special software, extremely easy to use due to the intuitive “Touch” screen.

Thanks to the latest generation technologies it is possible to access main features as:

- Storage of 49 programs, each of them with a 8-stop sequence in the bending operation

- Calculation of the machine maximum bending capacities with reference to the material size to be bent

- Graphic of the minimum bending radii

- Setting of springiness material estimate (spring back)

- Bend counter

- Remote connection “Industry 4.0”

Additional Functions:

-

Working mode: either manual or automatic

-

Change of measure unit: either inches or millimeters

-

100 MB hard disk

-

Alarm diagnosis

-

Maintenance notice

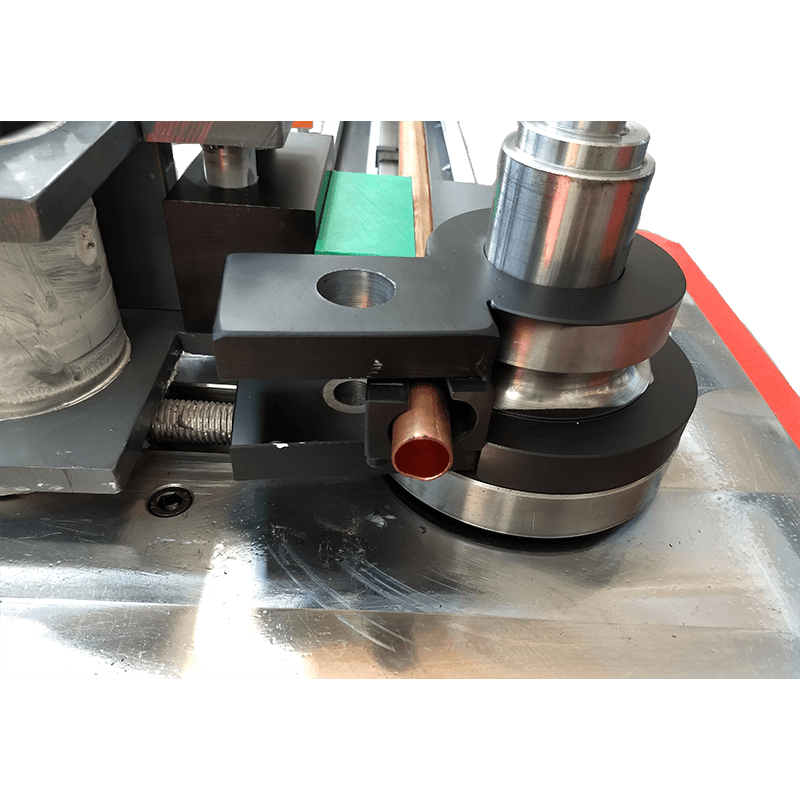

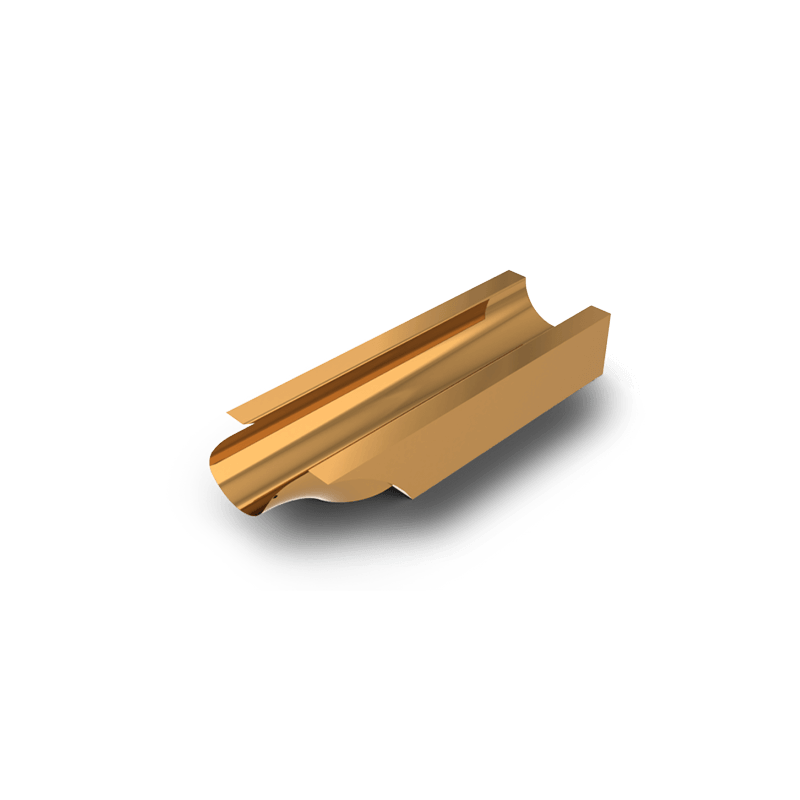

Wiper die

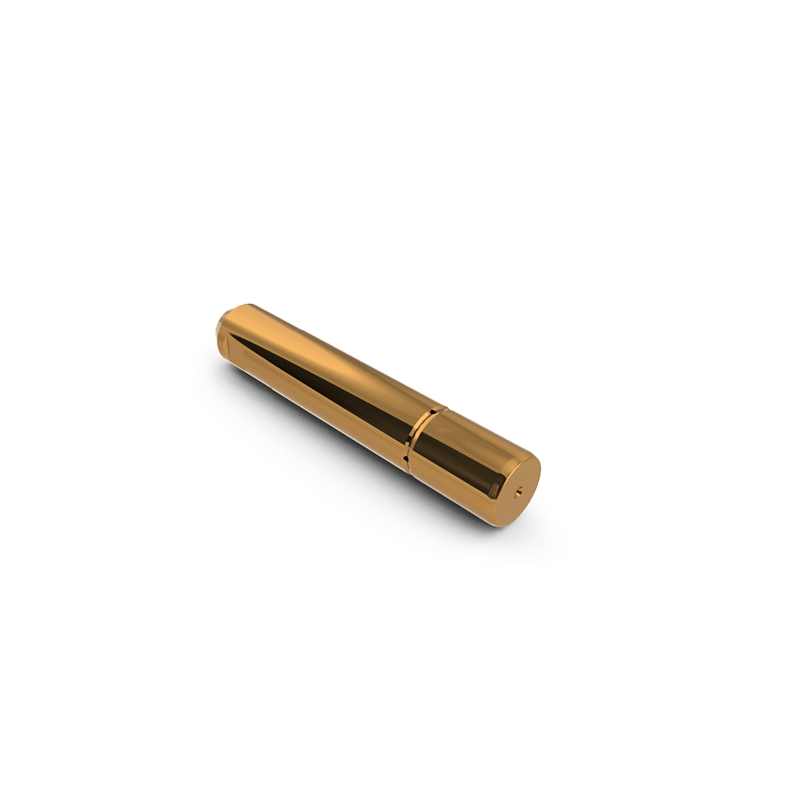

Fixed Mandrel

Foot Pedal Control

Digital Display Counter-Die Position

Eccentric Vise Clamping

Positioner

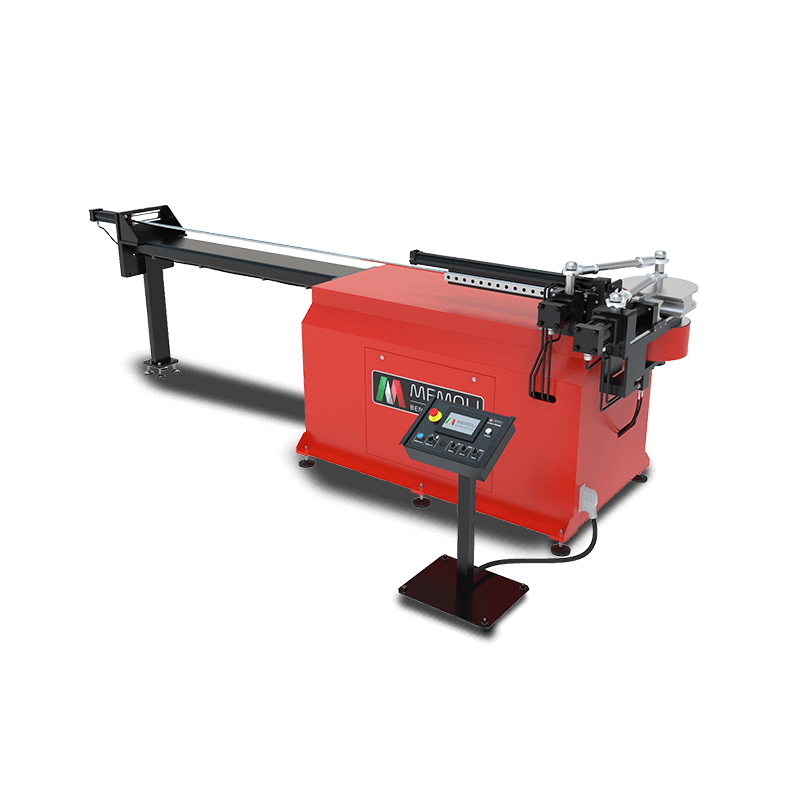

ETM-H Hybrid Semi-Automatic Mandrel Tube Bending Machines

The ETM-H range of semi-automatic hybrid tube bender is ideal for the machining of thin tubes without deformation of the processed tube: a compact, high-performance and economical solution. In semi-automatic bending machines of the ETM-H series, the bending function is performed automatically, while the feeding and rotation of the tube between the bends must be performed manually.

Simplicity, sturdiness and precision are the key features of this particularly cost-effective line.

These tube bending machines are particularly used for the production of small to medium batches, for prototyping, and for adaptation and maintenance work.

In tube processing with multiple bends, the positioner will greatly facilitate your work; in fact, this device through its system of stops allows the exact fixing of the tube length and rotation position between bends, ensuring an excellent degree of repeatability. As standard supply, this electric bending machine is equipped with a hydraulic mandrel extractor, hydraulic clamp die and pressure die, thus ensuring an excellent quality bend finish.

Our ETM-H semi-automatic hybrid bending machines can bend tubes with a diameter up to 90 mm diameter with maximum quality of finishing, with a minimum bending radius of 1 x the tube diameter. Extremely easy and fast to use thanks to the “Digital Bend Programming Touch Screen 2”, the software specially created for our machines is able to select as many as 100 programs with 10 bending angles each and with automatic correction of the spring back. In addition, the projects you make will be saved and programmed as repeatable.

Watch the videos

GENERAL FEATURES

- Electronic control “Digital Bend Programming Touch Screen 2”

- Remote connection “Industry 4.0”

- Separate control pulpit

- Adjustable clamping pressure

- Programmable early mandrel extraction for optimized bending quality

- Follower pressure die with automatic retraction

- Hollow shaft for using tooling for small radii

- Adjustable bending speed

- Usable length in accordance with customer

- Compact machine

- Positioning unit for length and rotation, incl. 3-jaw chuck / hydraulic chuck (optional)

- Useful tube length 1500 / 3000 / 6000 / 8000

- Mandrel lubrication system (optional)

TUBE BENDING SOFTWARE

Every ETM-H series machine is supplied with the “Digital Bend Programming Touch Screen 2” special software, extremely easy to use due to the intuitive “Touch” screen.

Thanks to the latest generation technologies it is possible to access main features as:

- Storage of 100 programs, each of them with a 10-stop sequences in the bending operation

- Adjustable bending speed

- Early mandrel extraction programming

- Spring back programming

- Bend counter

- Remote connection “Industry 4.0”

Maximum capacity (mm)

|

MATERIAL |

ETM-H 50 |

ETM- H 63 |

ETM-H 80 |

ETM-H 89 |

|---|---|---|---|---|

|

Fe 430 |

50 x 2,5 |

60 x 3 |

76 x 3 |

82,2 x 3 |

|

Aluminum |

60 x 4 |

60 x 7 |

76 x 4 |

90 x 3 |

|

INOX AISI 304 |

50 x 1,5 |

60 x 2 |

76 x 2 |

76 x 3 |

|

SQUARE PIPE |

40 x 2,5 |

50 x 1,5 |

60 x 2 |

65 x 4 |

Length and Rotation Measuring System With Digital Display

Wiper die

Fixed Mandrel

Jointed Mandrel

Foot Pedal Control

ACH CNC Tube Bender

3-axis CNC tube bender for the linear bending of tubes up to 65 mm diameter. The tube bending machines of the ACH series are fully automatic bending machines with CNC 3 axes: bending (Y axis), advancement (X axis) and rotation (Z axis).

This hybrid tube bender has been developed for the accurate bending of tubes and profiles. The main axes are electrically controlled, while the auxiliary axes are hydraulically controlled.

The extremely small bending head is made of steel with a chain-driven transmission to ensure more space in the sub-bending head; in this way, the machine can bend in a single cycle even tubes with the most complex geometries.

The setup times are extremely short and ensure great flexibility.

The ACH series of CNC mandrel tube bending machines is developed and produced entirely in Italy, in close collaboration with the main tube bending Companies.

Maximum capacity (mm)

|

MATERIAL |

ACH 45 |

ACH 65 |

|---|---|---|

|

Max steel tube to bend with mandrel |

45 x 3 |

65 x 4 |

|

Max steel tube to bend with interpolation |

40 x 3 |

60 x 3 |

|

Max aluminum alloy tube to bend with mandrel |

60 x 2 |

80 x 3 |

|

Max aluminum alloy tube to bend with interpolation |

50 x 2 |

65 x 3 |

General features

-

Carbon steel frame

-

Feasibility analysis thanks to the easy and intuitive 3D simulator

-

Primary axes handling with brushless CNC motors

-

Toggle lock closure

-

Programmable advance mandrel extraction

-

Bending with variable radius

-

Rear booster

-

Preparation for punching accessory – Up/Down mold opening

-

Compact and exposed bending head for maximum bending space

-

Separate control pulpit

Watch The Video

ACH SOFTWARE

All of ACH mandrel bending machines are equipped with MEMOLI interface – a 3D bending software, designed for tube bending applications. Extremely easy and intuitive, it allows you to program directly through the adjustment of LRA (length – rotation – angle). MEMOLI software is also compatible with a wide variety of CAD software programs (Autocad, Inventor, Solid Works, Pro Engineer, Rhinoceros etc.).

Among other strength points, it offers automatic spring back compensation, it memorizes tool configuration and geometry, and it has anti-collision properties for component feasibility, without prototyping or material waste.

• 3D Tube Development Graphics.

• Axis movement simultaneously.

• Calculation of tube length.

• Continuous monitoring of the machine.

• Software for anti-collision testing.

• Display of the graphic tool.

• Graphic display of the machine.

ANGLE BENDING ROLLS & COILING LATHES

Memoli angle rolls bending machines are technologically advanced machines, reliable and precise, able to guarantee an excellent bending quality and maximum productivity over time. Our bending machines are suitable for bending profiles and beams in steel, stainless steel and aluminum of different shapes and sizes; perfect for making all types of spiral stairs, spirals out of tube, flanges for pipes, greenhouses, handrails, tables, chairs, doors and even windows.

Made of welded steel sheet, our angle rolls bending machines are characterized by a high sturdiness, quality of finish and versatility, allowing the practitioners to carry out an infinity of circular shapes in all types of profile.

Memoli top quality bending machines will allow you to have the precision and strength that your projects require.

Click on the the drop down to find out more

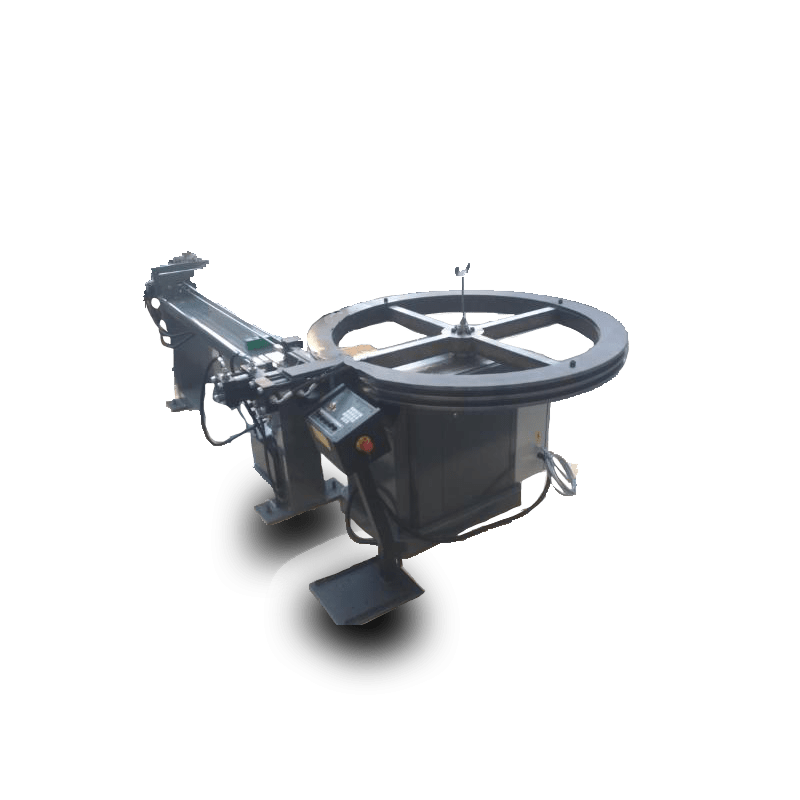

MEK 60-R CNC Angle Roll

The MEK 60-R three-roll hybrid profile bender was designed to meet the demands of an increasingly demanding customer base, with the need to bend all types of profiles and tubes with accuracy and very tight tolerances. The three driving rolls are driven by a powerful electric gearmotor that guarantees high positioning accuracy, while the independent planetary movement of the two bottom rolls is provided by two powerful hydraulic cylinders.

The Memoli MEK 60-R bending machine is equipped with high-strength shafts and rolls, side support system, touch screen and CNC control system.

Thanks to Memoli’s specially developed CNC bending software, this profile bending machine can work in manual, semi-automatic and automatic modes.

This latest generation software is based on a Windows PC with a touch screen display; bending programs can be created, managed and controlled intuitively without the operator needing to have any programming skills.

The 3D graphic simulation of the programmed workpiece will allow a visual check to be made before machining is performed.

GENERAL FEATURES

-

Three electric motorized rollers

-

Hydraulic planetary lower roller movement

-

Working position with vertical and horizontal axes

-

Working position with vertical and horizontal axes

-

Performing the bending process in one or more steps, even with different radii within a component

-

Creation of material library/spring back diagrams for all materials

-

Interface with CAD software

-

Networking and integration into the existing IT infrastructure

-

Creation, management and backup of program data independently of the workplace through network integration

-

Direct support from Memoli experts thanks to remote maintenance capability.

Technical specifications

|

|

MEK 60-R |

|---|---|

|

Motor Output |

KW 3,5 |

|

Rolling speed |

0-7 g/1’ |

|

Shaft diameters |

60 mm |

|

Roll diameters |

On request (220 mm std.) |

|

Weight |

900 kg |

|

Machine dimensions |

740 x 1020 x 1110 h. |

|

Console dimensions |

590 x 710 x 1200 h. |

* Machine data may be subject to change without notice

Maximum capacity (mm)

|

|

STANDARD ROLLS |

SPECIAL ROLLS |

||

|---|---|---|---|---|

|

Profile |

Dimension |

Ø INT. MIN. |

Dimension |

Ø INT. MIN. |

|

Max 70 x 15 |

500 |

Small sections |

150 |

|

|

Max 125x25 |

500 |

Small sections |

150 |

|

|

Max 40 x 40 |

500 |

Small sections |

150 |

|

|

Small sections |

500 |

Max Ø 50 Min no limit |

500 150 |

|

|

Special rolls only |

500 |

Max O.D. 60/(2’’SCH40) Min no limit |

500 150 |

|

|

Small sections |

500 |

Max 50 x 50 x 6 |

* |

|

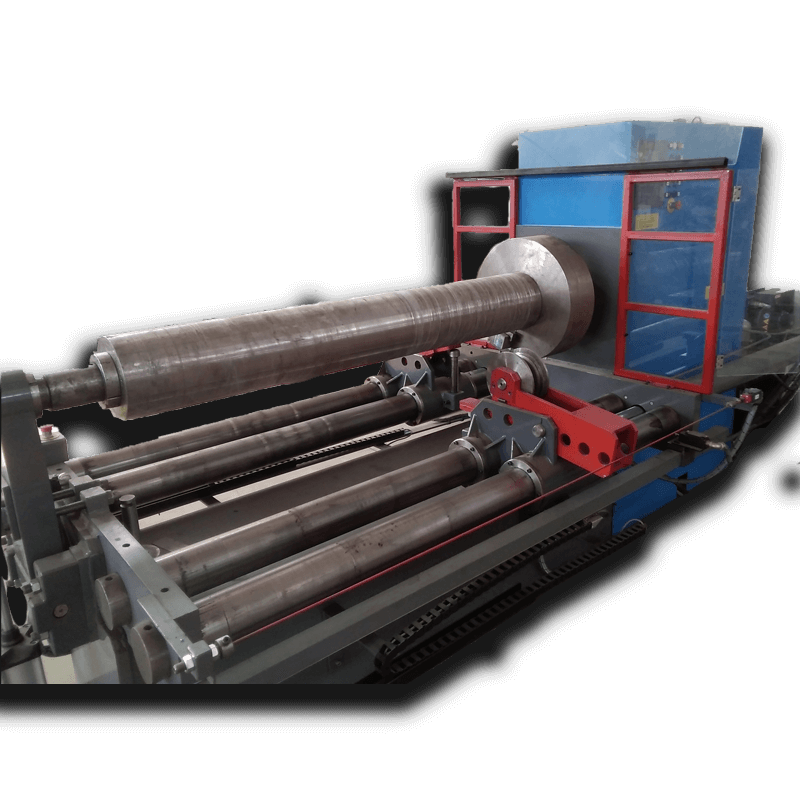

HLN Coiling Lathes

The HLN series of coiling lathes are completely electric CNC-controlled machines designed for the manufacture of springs and augers. Designed and built entirely by Memoli, they are an effective and efficient solution capable of machining round, flat, square bars and tubes. The design of our winding machines starts with the needs of each single Customer: we build machines specifically to achieve high final standards and optimize production costs.

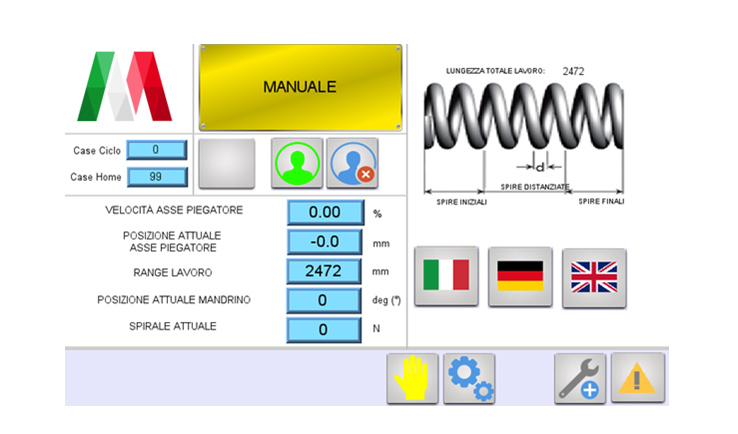

Their strength is not only the final product: thanks to the ‘CNC Coiling Program Touch Screen’, which provides the possibility to save your own designs as repeatable programs, operation is extremely easy and fast.

GENERAL FEATURES

-

CNC Coiling Program Touch screen with internal memory 500 programs, expandable and remote connection via USB

-

Left or right-handed winding, with constant or variable pitch

-

Quick spring extraction system with automatic release

-

Rapid tool change

-

Perimeter safety with photocells

-

Variable speed

-

Wire size Ø 2 to Ø 80 mm

-

Flat size max. 70 x 10 mm

-

Spring length max. 3000 mm

CNC Coiling Control

-

System with parameters for wire diameter variation

-

Winding speed adjustment

-

Automatic pitch adjustment

-

Internal memory 500 programs, expandable (optional)

-

Remote connection

-

Machine diagnostics

-

Correction and storage of material elasticity

SPECIAL MACHINES

One of Memoli's strong suites is the realization of special machines meant to bend and curve any metal material.

They are designed and manufactured on specific custom needs, combining the best technical solution with the budget possibility of our Customers, aiming at granting top high production rates and optimizing the costs. These machines are manufactured and assembled with top quality mechanical and electronic parts in order to grant them a higher level of reliability.

In order to manufacture our custom machines, our design project service is always at your complete availability for the analysis and feasibility of your projects for cost estimate, lay-out and final realization of the required suitable machine.

The design of our special machines originates from the analysis of the workpiece according to the customer’s individual needs: this way, we create tailored solutions by offering maximum flexibility in terms of construction and performance, with ad hoc features in order to achieve the goal.

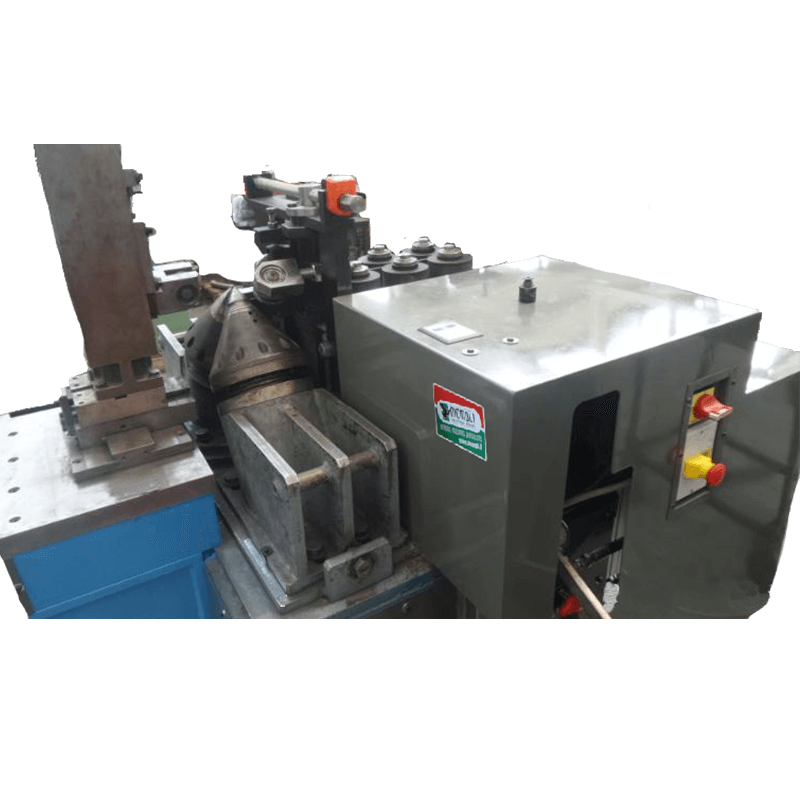

40 Ton Special Application Hydraulic Press Brake

Specially Designed Auger Forming Machine

Specially Designed ETM Large Radius Bender