MORI Iron Works Fine-Blanking & Forging Presses

Established in 1922 they have developed a reputation for quality, reliability and innovation that is unmatched.

What MORI has to offer

-

Hydraulic Fineblanking Presses -

Mechanical Fineblanking Presses -

Multi-Axis Servo Hydraulic One-Shot Forming Presses -

Orbital Forging Presses

Hydraulic Fineblanking Presses

Hydraulic Fineblanking Presses

Ideally suited for applications including automotive, aerospace and military that require tight tolerance fineblanked quality. MORI press systems deliver high throughput, minimal tool wear and unmatched repeatability.

SPECIFICATIONS:

FB (Hydraulic) |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

160 |

250 |

320 |

400 |

500 |

650 |

800 |

1000 |

1200 |

1500 |

||

Forces |

|||||||||||

Total force |

kN |

1600 |

2500 |

3200 |

4000 |

5000 |

6500 |

8000 |

10000 |

12000 |

15000 |

V-ring Force |

kN |

800 |

1200 |

1600 |

2000 |

2500 |

3200 |

4000 |

5000 |

6000 |

|

Counter Force |

kN |

400 |

600 |

800 |

1000 |

1250 |

1300 |

2000 |

2500 |

3000 |

|

CutterCutter Force |

kN |

300 |

400 |

600 |

700 |

||||||

Stroke Length |

mm |

20〜100 |

20〜140 |

20〜200 |

|||||||

Max Stroke |

SPM |

60 |

55 |

50 |

40 |

35 |

30 |

||||

Cutting speed |

mm/s |

3〜70 |

3〜60 |

3〜50 |

3〜45 |

3〜40 |

|||||

Max Approach Speed |

mm/s |

220 |

200 |

180 |

160 |

||||||

Max Decent Speed |

mm/s |

220 |

200 |

180 |

160 |

||||||

Material |

|||||||||||

Min Sheet Length |

mm |

2440 |

3000 |

3400 |

3600 |

3750 |

4000 |

||||

Width |

mm |

20〜200 |

40〜250 |

40〜320 |

40〜450 |

60〜550 |

|||||

Thickness |

mm |

10 |

15 |

16 |

20 |

||||||

Electric Power |

|||||||||||

Total Power |

KW |

56 |

69 |

82 |

102 |

136 |

160 |

180 |

192 |

230 |

|

Main Drive |

KW |

30 |

37 |

55 |

75 |

90 |

110 |

132 |

160 |

||

Hydraulic |

|||||||||||

Oil Cooler |

KW/h |

30 |

38 |

45 |

60 |

70 |

90 |

100 |

110 |

130 |

|

Oil Tank Capacity |

L |

850 |

1400 |

1600 |

2000 |

||||||

Press |

|||||||||||

A |

mm |

1445 |

1625 |

1725 |

1750 |

1825 |

1900 |

2040 |

2310 |

2310 |

2375 |

B |

mm |

1510 |

1840 |

1845 |

2030 |

2080 |

2130 |

2310 |

2790 |

2850 |

2950 |

C |

mm |

1435 |

1625 |

1815 |

1830 |

1850 |

1980 |

2200 |

2250 |

2250 |

2410 |

D |

mm |

2900 |

3400 |

3000 |

3300 |

3300 |

3400 |

3800 |

3900 |

4050 |

4400 |

E |

mm |

1465 |

1715 |

1450 |

1450 |

1450 |

1450 |

1450 |

1450 |

1450 |

1450 |

F |

mm |

1265 |

1415 |

1150 |

1150 |

1140 |

1080 |

1060 |

1060 |

1040 |

1010 |

G |

mm |

0 |

0 |

480 |

530 |

665 |

870 |

1175 |

1520 |

1660 |

2050 |

H |

mm |

2460 |

2600 |

2660 |

2700 |

2840 |

3200 |

3500 |

3800 |

3800 |

4050 |

I |

mm |

7010 |

7440 |

7550 |

7780 |

7830 |

8430 |

8765 |

9000 |

9100 |

9775 |

Reference drawing

FB (Hydraulic) |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

160 |

250 |

320 |

400 |

500 |

650 |

800 |

1000 |

1200 |

1500 |

||

Tool Space |

|||||||||||

Upper Bolstera |

mm |

500 |

650 |

800 |

850 |

900 |

1000 |

1100 |

1150 |

1200 |

|

b |

mm |

500 |

600 |

700 |

750 |

850 |

900 |

1000 |

1100 |

||

c |

mm |

75 |

|||||||||

Lower Bolstere |

mm |

500 |

650 |

800 |

850 |

900 |

1000 |

1100 |

1150 |

1150 |

1400 |

f |

mm |

750 |

900 |

950 |

1000 |

1050 |

1200 |

1300 |

1300 |

1500 |

|

g |

mm |

75 |

|||||||||

AdapterPlate |

|||||||||||

X |

mm |

420 |

550 |

650 |

750 |

800 |

950 |

1000 |

1200 |

||

Y |

mm |

500 |

650 |

750 |

800 |

950 |

1000 |

1200 |

|||

Z |

mm |

80 |

100 |

140 |

160 |

200 |

|||||

Upper InsertRing Du |

mm |

320 |

400 |

500 |

720 |

||||||

du |

mm |

180 |

300 |

380 |

580 |

||||||

Tu |

mm |

72 |

80 |

120 |

140 |

175 |

|||||

Lower InsertRing Dl |

mm |

250 |

400 |

500 |

720 |

||||||

dl |

mm |

250 |

400 |

500 |

720 |

||||||

Tl |

mm |

72 |

80 |

120 |

140 |

175 |

|||||

Shut Height |

mm |

230〜320 |

300〜380 |

320〜400 |

360〜460 |

400〜520 |

|||||

MaxOpen Height |

mm |

370 |

520 |

540 |

600 |

640 |

660 |

700 |

|||

Reference drawing

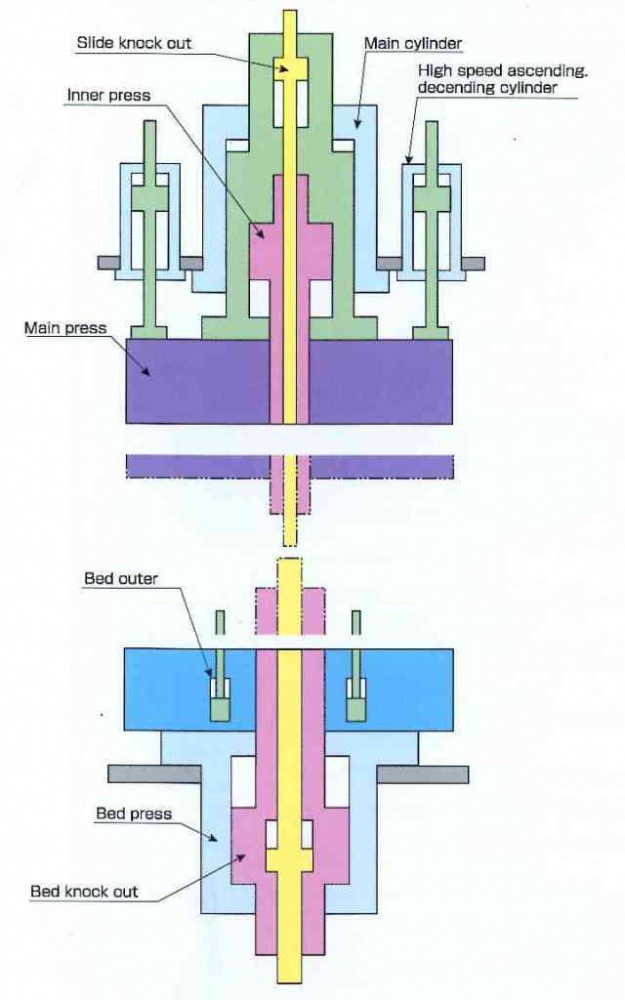

Mechanical Fineblanking Presses

Mechanical Fineblanking Presses

SPECIFICATIONS:

MFB (Mechanical) |

|||||

|---|---|---|---|---|---|

100 |

160 |

200 |

250 |

||

Forces |

|||||

Total force |

kN |

1000 |

1600 |

2000 |

2500 |

V-ring Force |

kN |

300 |

600 |

800 |

1400 |

Counter Force |

kN |

240 |

400 |

500 |

800 |

CutterCutter Force |

kN |

70 |

120 |

150 |

100 |

Stroke Length |

mm |

50 |

58 |

60 |

67.5 |

Max Stroke |

SPM |

100 |

|||

Cutting speed |

mm/s |

||||

Max Approach Speed |

mm/s |

||||

Max Decent Speed |

mm/s |

||||

material |

|||||

Min Sheet Length |

mm |

1600 |

1700 |

1800 |

2400 |

Width |

mm |

20〜160 |

20〜200 |

20〜150 |

20〜150 |

Thickness |

mm |

6 |

8 |

6 |

6 |

Electric Power |

|||||

Total Power |

KW |

15 |

35 |

35 |

52 |

Main Drive |

KW |

5.5 |

22 |

22 |

30 |

Hydraulic |

|||||

Oil Cooler |

KW/h |

2.5 |

4 |

5 |

7.5 |

Oil Tank Capacity |

L |

150 |

250 |

150 |

|

Press |

|||||

A |

mm |

1160 |

1300 |

1100 |

2100 |

B |

mm |

1110 |

1190 |

1200 |

1900 |

C |

mm |

1150 |

1280 |

1350 |

1290 |

D |

mm |

2650 |

3100 |

3160 |

3680 |

E |

mm |

1470 |

1710 |

1714 |

1257 |

F |

mm |

1390 |

1620 |

1624 |

894 |

G |

mm |

0 |

0 |

0 |

785 |

H |

mm |

1620 |

3030 |

3250 |

2120 |

I |

mm |

3810 |

2760 |

3550 |

7400 |

Reference drawing

MFB (Mechanical) |

|||||

|---|---|---|---|---|---|

100 |

160 |

200 |

240 |

||

Tool Space |

|||||

Upper Bolstera |

mm |

430 |

550 |

560 |

650 |

b |

mm |

430 |

550 |

560 |

650 |

c |

mm |

75 |

|||

Lower Bolstere |

mm |

430 |

560 |

650 |

|

f |

mm |

480 |

620 |

560 |

650 |

g |

mm |

75 |

110 |

75 |

|

AdapterPlate |

|||||

X |

mm |

||||

Y |

mm |

||||

Z |

mm |

||||

Upper InsertRing Du |

mm |

160 |

260 |

320 |

|

du |

mm |

70 |

120 |

250 |

|

Tu |

mm |

30 |

45 |

80 |

|

Lower InsertRing Dl |

mm |

250 |

300 |

320 |

|

dl |

mm |

140 |

180 |

250 |

|

Tl |

mm |

50 |

60 |

90 |

|

Shut Height |

mm |

190〜280 |

210〜340 |

305〜355 |

360〜410 |

MaxOpen Height |

mm |

330 |

398 |

477 |

477.5 |

Reference drawing

Multi-axis servo hydraulic One Shot Forming Presses

Multi-axis servo hydraulic One Shot Forming Presses

Features

The One Shot Forging process enables cost reduction due to high-mix low-volume production.

One-shot process from transfer or progressive processing.

Promote compact equipment and in lining.

Has deployed a system to manage data molding. Each axis position, monitoring the pressure waveform data, even small changes can be confirmed for each axis at the time of molding.

According to a Customer’s use, combination change of an axis and servo control system software changes are possible.

Specifications of the One-shot forming press. |

||||

|---|---|---|---|---|

Form |

MMF1000-M338axis |

MMF500-M325axis |

MMF200-M325axis |

|

Output |

(kN) |

10000 |

5000 |

2000 |

Open height |

(mm) |

1400 |

1400 |

1000 |

No-load speed |

(mm/S) |

150 |

150 |

150 |

Maximum stroke length |

(mm) |

600 |

500 |

450 |

Diameter of main cylinder |

(mm) |

φ850 |

φ620 |

φ340 |

The total power |

(kW) |

560 |

320 |

120 |

-

Type of One-shot forming press

-

MMF(Output ton)─ M(Upper axis number)(Lower axis number)

Reference Drawing & Sample Parts

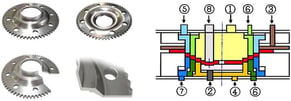

Orbital Forging Presses

Orbital Forging Presses

FEATURES:

Orbital forging in order to pressure forming locally, can be formed by the power of 1/5 to 1/10 for the general press molding was carried out it upsetting.

Therefore, it can significantly reduce the investment and basic facilities such as, Press, Tool, Foundation work.

Less restraint of the tool and the material, processing range is greatly improved, can effectively mold precision parts, including thin-walled items.

The orbital motion has four types of motion, can be formed in the shape of a variety of products.

Noise and vibration are greatly reduced compared to traditional presses, improving the working environment.

Tool change time is short, it suitable for high-mix low-volume production.

Registration function of the data processing is included. Processing conditions can be reproduced immediately that you have registered.

SPECIFICATIONS:

Hydraulic orbital forging presses |

||||

|---|---|---|---|---|

Form |

MCOF-250 |

MCOF-400 |

MCOF-650 |

|

Output |

(kN) |

2500 |

4000 |

6500 |

Knockout Output |

(kN) |

300 |

700 |

1300 |

Pressing speed |

(mm/s) |

3~30 |

3~25 |

3~25 |

The number of orbital rotation |

(rpm) |

Max. 320 |

Max. 300 |

Max. 280 |

Stroke Length |

(mm) |

220 |

320 |

450 |

Stroke adjustment amount |

(mm) |

75mm belowthe upper limit |

40mm belowthe upper limit |

100mm belowthe upper limit |

Knock-out stroke |

(mm) |

65 |

100 |

115 |

Diameter of the largest product |

(mm) |

160 |

210 |

240 |

Total power |

(kW) |

89 |

220 |

265 |

Hydraulic oil tank |

(l) |

1000 |

1300 |

1500 |