MEC Wire Forming offers wire forming machines for torsion springs, coiling machines for compression springs, canted coil springs, oval springs and three-dimensional bending springs and extension spring machines for English loops, side loops and U hooks.

Extension Spring Machines

Machines specializing in the production of extension springs, including English, German, and U hooks.

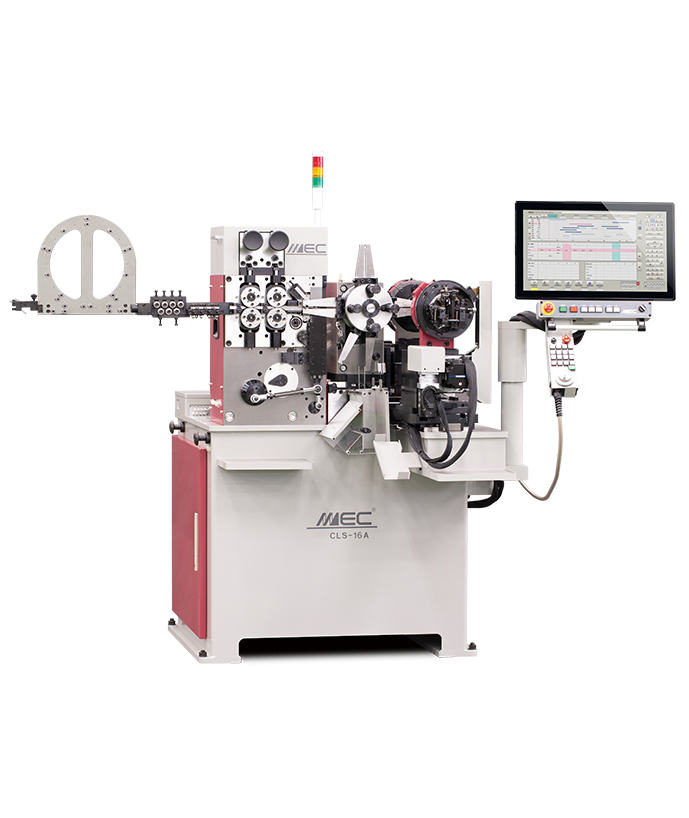

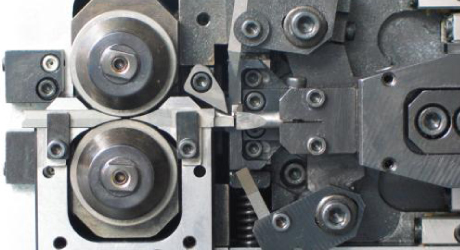

CLS-16A Extension Spring Machine

CLS-16A Extension Spring Machine

An extension spring machine with a maximum wire diameter of 1.6 mm.

Maintains the popular high-speed productivity for English loops and bicyclic loops and greatly improves the preparation for German hooks, U hooks, and other atypical hooks.

Features:

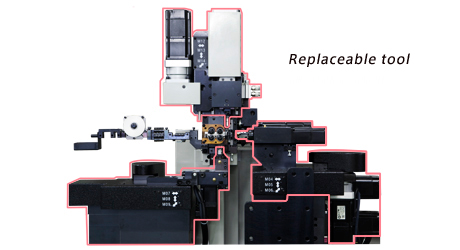

Advanced cut slide function

-

-

The alignment of the cut tool and core does not require readjustment after being decided once. As the cut slide and core slide are both located on the center slide, the positional relationship of the two tools does not change, meaning that readjustment is not required.

-

The cutting method can be changed. You can easily switch between oscillating cut and straight cut.

-

The oscillating cut bearing (oscillation) can be adjusted. Adjust the bearing using the eccentric pin on the slide.

-

Enable high-speed production of extension springs with a beautiful hook shape

- A dedicated extension spring machine for wire diameters of 0.5 to 1.6 mm.

- Produces the beautiful hook shape expected of the CLS series.

- Enables a much higher speed of production than general torsion machines.

- The 11 axis control of the CLS-16II enables many locations to be controlled by values, including the coiling point for 3D operations, and provides high performance preparation and reproduction.

Make the production of German hooks and U hooks easier

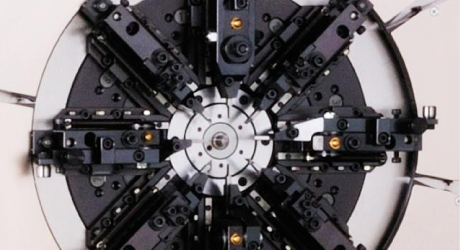

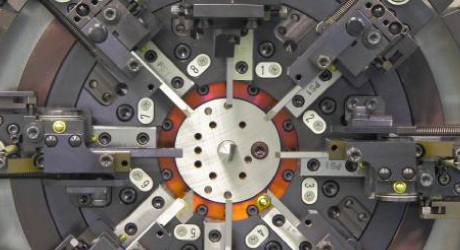

The CLS-16II maintains the production performance of English loops and bicyclic loops, while greatly enhancing the ease of producing German hooks and U hooks. The number of Hooking tools for processing the hooks has been increased from three to six, to enable easier adjustment and stronger coil retention. Pattern programs Programs are automatically generated for the 3D coiling point operations and wire feed amounts required for the shapes of same diameter, different diameter, one-side U hooks, and both-side U hooks.

Optional Equipment

-

IS-1x shape detection unit with camera

-

Two cameras measure the hook shape on both sides

-

Stage sensor units (various)

Specifications:

|

Format |

CLS-16II |

|---|---|

|

Wire diameter |

0.5~1.6mm |

|

Outside coil diameter |

20mm |

|

D/d |

4 or more (*) |

|

Spring Length |

Wire diameter x 10 coils, up to 140 mm (*) |

|

Feed Axis |

Minimum input 0,001 mm, maximum speed 165 m/min |

|

Point Axis |

Resolution 0.001mm |

|

Initial tension Axis |

Resolution 0.001° |

|

Torsion Axis |

Resolution 0.001° |

|

Cam axis |

Resolution 0.001° |

|

Transfer axis |

Resolution 0.001° |

|

Clamp axis |

Resolution 0.001° |

|

Tooling axis x 2 |

Resolution 0.001° |

|

Tooling slide axis x 2 |

Resolution 0.001° |

|

Power source |

AC 200V 3-Phase, 20A |

|

Solenoid valves |

8pcs |

|

Service air pressure |

0.5MPa(5.1kgf/cm2) |

|

Net weight |

1,200kg |

|

Control device |

OS Windows7 |

|

Display |

21.5 inch touch panel |

|

External memory |

USB thumb drive |

|

Service Temp. |

0~40°C |

(*) May differ according to the wire diameter

CLS-10A Extension Spring Machine

CLS-10A Extension Spring Machine

Standard extension machine. Double loop end is available. The machine enables high speed production.

Your spring is transferred after forming. Shape forming and a production check are done in each stage.

Features:

Enables high-speed production of extension springs with a beautiful hook shape.

-

A dedicated machine for extension springs with a wire diameter of 0.12 mm to 1.0 mm.

-

Produces a more beautiful hook shape than any other machine.

-

Enables a much higher speed of production than general torsion machines.

-

Programs for a wide variety of hooks are provided.

Beautiful hook shape

-

The CLS-10V can produce English hooks, German hooks, U hooks, side hooks, and Indian hooks.

-

Enables creation of extended hooks in which the two hooks are wound together neatly.

-

Enables processing without a straight line at the end of the cut.

-

Enables processing without an opening at the end of the cut.

High-speed production

Maximum production speed of 120 items per minute – a much greater production volume than standard (quill type) torsion machines.

Optional Equipment

-

IS-1X Shape detection unit with camera.

-

6 Point simultaneous measurement with 2 cameras.

Specifications:

|

Wire Diameter |

0.12~1.0mm(.0047-.0394'') (See Note) |

Feed Axis Motor |

600W AC Servo Motor |

|---|---|---|---|

|

Outside Coil Diameter |

1~12mm(.0394-.4724'') |

Cam Axis Motor |

750W AC Servo Motor |

|

Spring Length |

3.0~100mm(.0984-3.937'') |

Power Supply |

AC200V, 20A, 3phase |

|

Direction of Helix |

Clockwise |

Solenoid Valves |

4pcs |

|

Maximum Feed Length |

9999mm(393.66'') |

Air Requirements |

0.5MPa(5.1㎏f/c㎡) |

|

Production Speed |

120ppm at max. |

Weight |

440㎏(970lbs) |

〔Note〕 For wire diameter from 0.9 ~ 1.0mm, D/d must be greater than 6.

Wire Forming Machines

Offering superior performance and accuracy, Mec’s six wire forming machine lines provide high-speed forming for a wide range of wire, including thick or thin diameter, rectangular shaped or soft metal. Our wire forming machines are designed with today’s demanding challenges in mind. Operator-friendly controls allow for quick preparation.

DZ-3 Wire Forming Machine

DZ-3 Wire Forming Machine

Ultra-thin wire springs take a new step forward.

The union of high-accuracy high-speed coil processing and freedom of bending opens up a new world of shapes.

Features:

The union of high-accuracy high-speed coil processing and bending

- A coiling torsion machine for wire diameters of 0.02 mm to 0.3 mm.

- Has coil processing ability equivalent to that of coiling machines.

- Three 3D slides enable freedom of bending. The operations required for tool changers and R servos can be assigned to each of the three 3D slides.

Free modular design

The system enables different units to be attached to each of the three 3D slides. Can be replaced with various optional units.

A variety of attractive optional units

-

Feed pressure servo unit

-

Roller servo point unit

-

Ultra-thin wire guide holder

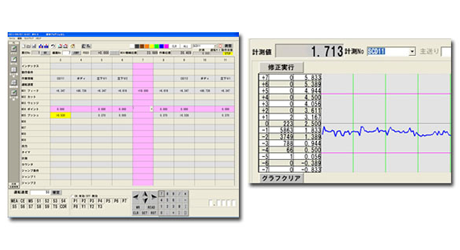

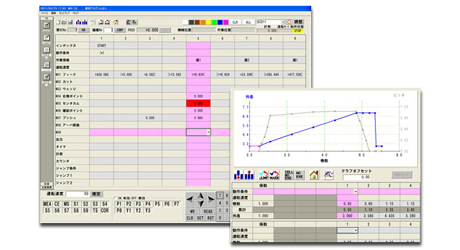

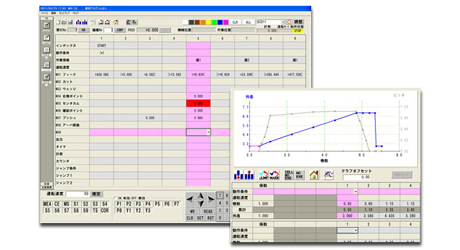

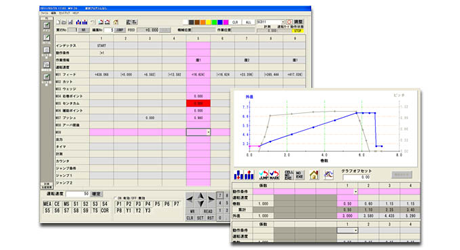

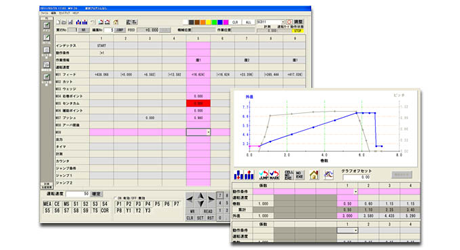

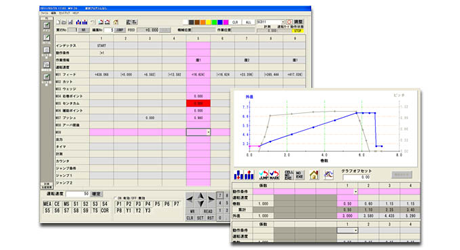

Dedicated MNO Program for Spring Production

- Easy operations for quicker preparation.

- High resolution for controlling the latest servo motors.

- Allows varied control based on measurement results, such as the pitch and diameter.

- Common program for both torsion machines and coiling machines.

- Includes a motor sensor system.

- Versatile production management screen and production data collection function.

|

Format |

DZ-3 |

|---|---|

|

Standard supported wire diameter |

0.02~0.3mm |

|

Maximum outer diameter |

8 |

|

D/d |

3.5 or higher |

|

Supported wire diameter when using an ultra-thin holder (OP) |

0.02~0.1mm |

|

Feed Axis |

0.001mm |

|

Pitch Axis |

0.001° |

|

Arbor Axis |

0.001° |

|

Left/right 3D table axis |

0.0001mm |

|

Up 3D slide axis |

0.001mm |

|

Tool changer axis |

0.001° |

|

R Servo Axis |

0.001° |

|

Solenoid valves |

4pcs(Max 8pcs available) |

|

Service air pressure |

Max 0.5Mpa |

|

Power source |

3-Phase, AC 200V, 45A |

|

Net weight |

850kg |

|

Control device |

OS Windows7 |

|

Display |

17'' TFT color LC Display |

|

External memory |

USB memory |

|

Service Temp. |

0~40℃ |

TM-3II Wire Forming Machine

TM-3II Wire Forming Machine

The TM-3 has evolved into the ultimate forming machine for small diameter wire.

The TM-3II contains the optimal tool rotation system for small diameter wire to maintain a constant wire line.

Features:

Table rotating torsion machine for wire diameters of 0.05 mm to 0.3 mm

-

Does not place a burden on the wire, preventing it from twisting.

-

Also suitable for special stock.

-

Equipped with 11 standard axes: feed, table rotation, 8 slides, and quill rotation.

-

Up to 3 optional RR servos can be added.

Dedicated MNO Program for Spring Production

-

Easy operations for quicker preparation.

-

High resolution for controlling the latest servo motors.

-

Allows varied control of axes based on measurement results.

-

Common program for both torsion machines and coiling machines.

-

Includes a motor sensor system.

-

Versatile production management screen and production data collection function.

We've taken the popular TM-3 to the next level

-

The TM-3II is based on the popular TM-3, but with greatly improved operability and accuracy.

-

Angles where tools cannot enter have been eliminated from the table circumference.

-

Includes a correction function to ensure the slide does not move forward or backward when the table is rotated in the processing position.

-

The feed unit has been revised to greatly improve wire line performance.

-

-

All slides can be used as a sensor

-

Motor sensor system (can be used for measuring the bend angle, free length, touch sensor, outer diameter, etc.)

Optional Equipment

-

MSD-1 sensor with servo motor

-

Can be used to measure the free length and outer diameter.

-

IS-1 shape detection unit with camera

|

Wire dia. |

0.05~0.3mm |

Control device |

Max. 16-axis to be controlled by computer - OS Windows XP |

|

|---|---|---|---|---|

|

Index |

D/d 4 or more |

Display |

17'' TFT color LC Display |

|

|

Twirl distance |

Radius 4mm(15mm to machine face) |

External memory |

USB memory |

|

|

Slides |

Body slide |

1 unit |

Service Temp. |

0 ~ 40°C |

|

Bending slide |

3 units |

Power source |

AC 3-Phase, 200V, 20A |

|

|

Cut slide |

4 units |

Service air pressure |

Max 0.5 Mpa |

|

|

RR Servo slide |

Option 3 units at max. |

Net weight |

450 kg |

|

TM-8A Wire Forming Machine

TM-8A Wire Forming Machine

The TM-8 has evolved into the ultimate forming machine for small diameter wire.

The TM-8A contains the optimal tool rotation system for small diameter wire to maintain a constant wire line.

Features:

Table rotating torsion machine for wire diameters of 0.2 mm to 0.8 mm

-

Does not stress the wire, preventing it from twisting.

-

Also suitable for special stock.

-

Equipped with 11 standard axes: feed, table rotation, 8 slides, and quill rotation.

-

Up to 3 optional RR servos can be added.

Dedicated MNO Program for Spring Production

-

Easy operations for quicker preparation.

-

High resolution for controlling the latest servo motors.

-

Allows varied control of axes based on measurement results.

-

Common program for both torsion machines and coiling machines.

-

Includes a motor sensor system.

-

Versatile production management screen and production data collection function.

We've taken the popular TM-8 to the next level.

-

The TM-8II is based on the popular TM-8, but with greatly improved operability and accuracy.

-

Angles where tools cannot enter have been eliminated from the table circumference.

-

Includes a correction function to ensure the slide does not move forward or backward when the table is rotated in the processing position.

-

The feed unit has been revised to greatly improve wire line performance.

-

All slides can be used as a sensor.

-

Motor sensor system (can be used for measuring the bend angle, free length, touch sensor, outer diameter, etc.)

Optional Equipment

-

MSD-1 sensor with servo motor: Can be used to measure the free length and outer diameter.

-

Slip sensor for detecting slips in wire feeding

-

IS-1 shape detection unit with camera

Specifications:

|

Wire dia. |

0.2~0.8mm |

Control device |

Max. 16-axis to be controlled by computer - OS Windows XP |

|

|---|---|---|---|---|

|

Index |

D/d 4 or more |

Display |

17'' TFT color LC Display |

|

|

Twirl distance |

Radius 45mm available using square quill |

External memory |

USB memory |

|

|

Slides |

Body slide |

1 unit |

Service Temp. |

0~40°C |

|

Bending slide |

3 units |

Power source |

AC 200V, 3-Phase, 20A |

|

|

Cut slide |

4 units |

Service air pressure |

Max 0.5Mpa. |

|

|

RR Servo slide |

Option 3 units at max. |

Net weight |

450 kg |

|

TM-20M Wire Forming Machine

TM-20M Wire Forming Machine

This tool rotation system is optimal for special wires such as soft wire and rectangular wire.

The TM-20 includes the latest MNO control system to enable anyone to easily create programs.

Features:

Dedicated MNO Program for Spring Production

-

Easy operations for quicker preparation.

-

High resolution for controlling the latest servo motors.

-

Allows varied control of axes based on measurement results.

-

Common program for both torsion machines and coiling machines.

-

Includes a motor sensor system.

-

Versatile production management screen and production data collection function

We've taken the popular TM-20 to the next level

-

The 20M is based on the popular TM-20, but with greatly improved operability and accuracy.

-

Includes a correction function to ensure the slide does not move forward or backward when the table is rotated in the processing position.

-

The feed unit has been revised to greatly improve wire line performance.

-

-

All slides can be used as a sensor.

-

Motor sensor system (can be used for measuring the bend angle, free length, touch sensor, outer diameter, etc.)

Table rotating torsion machine for wire diameters of 0.5 mm to 2.0 mm

-

Does not place a burden on the wire, preventing it from twisting.

-

Also suitable for special stock.

-

Equipped with 11 standard axes: feed, table rotation, 8 slides, and quill rotation.

-

Up to 3 optional RR servos can be added.

Optional Equipment

-

MSD-1 sensor with servo motor

-

Can be used to measure the free length and outer diameter.

-

IS-1 shape detection unit with camera

Specifications:

|

Wire dia. |

0.5~2.0mm |

Control device |

Max. 16-axis to be controlled by computer - OS Windows XP |

|

|---|---|---|---|---|

|

Index |

D/d 4 or more |

Display |

17'' TFT color LC Display |

|

|

Twirl distance |

Radius 68mm |

External memory |

USB memory |

|

|

Slides |

Body slide |

1 unit |

Service Temp. |

0~40°C |

|

Bending slide |

3 units |

Power source |

3-Phase, AC 200V, 25A |

|

|

Cut slide |

4 units |

Service air pressure |

Max 0.5 MPa |

|

|

RR Servo slide |

3 units Option |

Net weight |

1,500 kg |

|

VM-26 Wire Forming Machine

VM-26 Wire Forming Machine

The new mechanism and 16–axis servo motor enable a wide range of motions.

Simply add tools and a program and the VM-26 is ready for production.

Features:

A torsion machine with 16-axis control for wire diameters of 1.0 mm to 2.6 mm

-

Equipped with 16 standard axes: feed, feed front/back, quill rotation, wire rotation, top table left/right, bottom table left/right, various slides, and 2 R servo slides.

-

Deep with a long slide stroke, providing a wide clearance space.

Mechanical parts

-

The feed unit rotation mechanism of the VM series enables high-speed, smooth wire rotation as a result of its small moment of inertia. This is because the center of gravity is the wire line, which is also the center of rotation.

-

The feed unit has an integrated quill and is controlled to move forward and backward.

-

The main table is divided into top and bottom halves, and each half moves left and right. The initial tension axis, making pitch, tool groove alignment, etc. are set in the program.

-

Enables a wide clearance space with a quill depth of 120 mm and slide stroke of 140 mm.

Dedicated MNO Program for Spring Production

-

Easy operations for quicker preparation.

-

High resolution for controlling the latest servo motors.

-

Allows varied control of axes based on measurement results.

-

Common program for both torsion machines and coiling machines.

-

Includes a motor sensor system.

-

Versatile production management screen and production data collection function.

Optional Equipment

IS-1 shape detection unit with camera

Specifications:

|

Wire dia. |

0.5~2.0mm |

Control device |

Max. 16-axis to be controlled by computer - OS Windows XP |

|

|---|---|---|---|---|

|

Index |

D/d 4 or more |

Display |

17'' TFT color LC Display |

|

|

Twirl distance |

Radius 68mm |

External memory |

USB memory |

|

|

Slides |

Body slide |

1 unit |

Service Temp. |

0~40°C |

|

Bending slide |

3 units |

Power source |

3-Phase, AC 200V, 25A |

|

|

Cut slide |

4 units |

Service air pressure |

Max 0.5MPa. |

|

|

RR Servo slide |

3 units Option |

Net weight |

1,500 kg |

|

GF-8 Wire Forming Machine

GF-8 Wire Forming Machine

Ultra-thin wire springs take a new step forward.

The union of high-accuracy high-speed coil processing and freedom of bending opens up a new world of shapes.

Features:

A torsion machine with 6-axis control for wire diameters of 0.2 mm to 0.8 mm

- Cam alignment is not required as the 8 slides can be numerically controlled in the program.

- Achieves high-speed preparation at a reasonable price.

- Equipped with 6 standard axes: feed, quill, and 4 slides.

- Optional R servos (spinners) are provided (up to 4 can be attached).

- Optional S servos are provided for individual slide operations.

Dedicated MNO Program for Spring Production

-

Easy operations for quicker preparation.

-

High resolution for controlling the latest servo motors.

-

Allows varied control of axes based on measurement results.

-

Common program for both torsion machines and coiling machines.

-

Includes a motor sensor system.

-

Versatile production management screen and production data collection function.

Optional Equipment

-

R servo unit

-

S servo unit

-

Capacitance level sensor

-

IS-1 shape detection unit with camera

Specifications:

|

Wire dia. |

0.2~0.8mm |

Control device |

Max. 16-axis to be controlled by computer - OS Windows XP |

|

|---|---|---|---|---|

|

Index |

D/d 4 or more |

|||

|

Twirl distance |

Radius 36mm (when square quill is applied) |

Display |

17'' TFT color LC Display |

|

|

Slides |

Slide base |

8 units |

External memory |

USB memory |

|

Body slide |

1 unit |

Service Temp. |

0~40℃ |

|

|

Bending slide |

3 units |

Power source |

3-Phase, AC 200V, 20A |

|

|

Cut slide |

4 units |

Service air pressure |

Max. 0.5 MPa |

|

|

Option |

R servo slide |

2 units |

Net weight |

450kg |

NI-26A Torsion Spring Machine

NI-26A Torsion Spring Machine

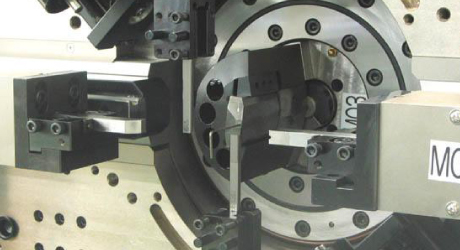

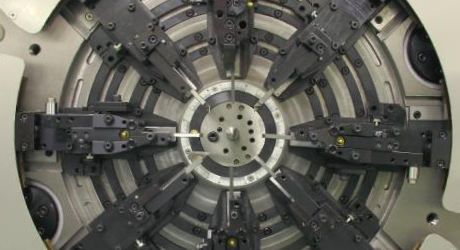

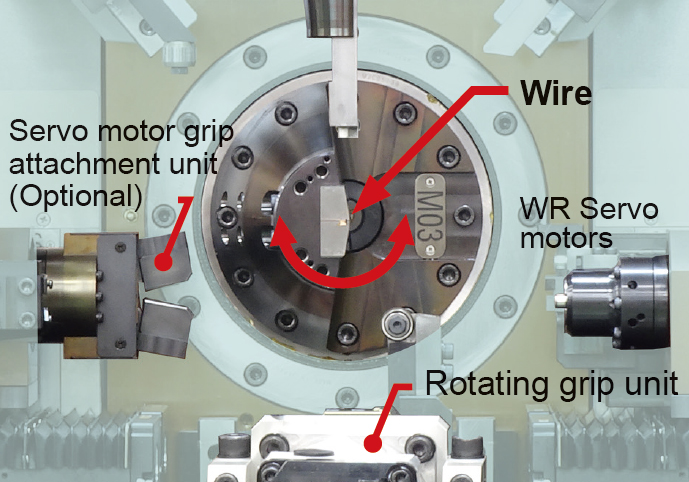

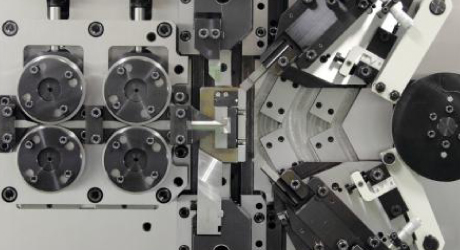

26-Axis CNC Multi-Wire Forming Machine

A multi-functional forming machine that enables various wire-processing realizes high value-added forming and high productivity.

Features:

Free form processing

- Intuitive operation is possible with each high-speed 3D slides on the top and bottom and each high-speed 3D dual slides on the left and right sides.

- It dramatically expands the application range of forming with the left and right double rotary (WR) servo motors, the upper rotary servo motor, the front rotating grip unit for secondary forming, and the newly developed wire rotary feed mechanism as the standard equipment.

High-precision processing

-

The newly developed bending sensor BS function realizes high-precision bending.

-

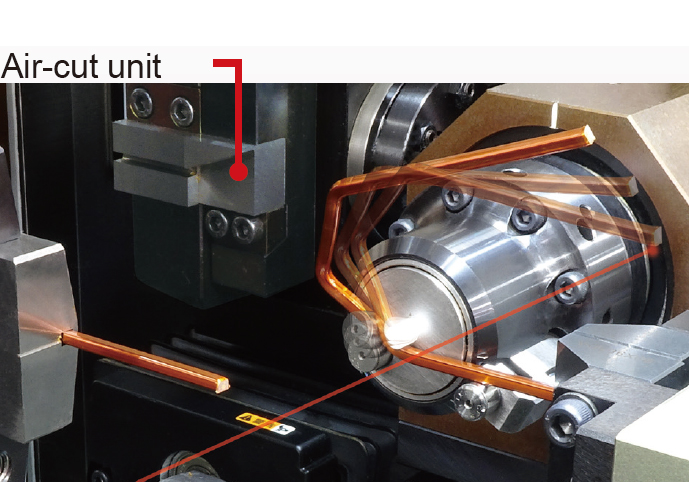

With the high-rigidity air-cut unit, it cuts without quill. It prevents wear of quill and achieving beautiful cross section with quiet processing.

-

The rotating grip unit and double rotary servo motors facilitate post-processing after wire cutting and support high value-added processing.

Reduced setup time due to high repeatability

No screw adjustment is required when installing the tool. Advanced adjustment is possible with a NC program, greatly reducing the setup time.

Newly developed software "MNO2" with excellent operability

- The program editing function has greatly evolved, and the new navigation system function and touch screen make it easier to create programs and shorten the setup time.

- Highly efficient production is supported by a versatile production control screen and production data collection function.

Support for IOT

The Wi-Fi function built into the newly developed spring forming program "MNO2" as standard allows you to check the operating status of the machine from your computer or smartphone.

Specifications:

|

Model |

NI-26A |

|

|---|---|---|

|

Wire diameter |

ø1.0 ~ ø2.6 mm |

|

|

Stroke (Quill) |

Max 150 mm |

|

|

Stroke (After grip) |

Max 330 mm |

|

|

D/d index |

4 or more |

|

|

Feed axis* |

0.0001 mm |

|

|

Feed speed |

Max 118 m/min |

|

|

Number of axes |

26 axis (Max 30 axis) |

|

|

Solenoid valves |

5 ports (Max 8 ports) |

|

|

Air pressure |

Max 0.5 MPa |

|

|

Power source |

3-phase, AC 200V, 30A |

|

|

Net weight |

4,150 kg |

|

|

Control device |

OS Windows |

|

|

Software |

MNO2 |

|

|

Display |

21.5" full HD touch screen |

|

|

External memory |

USB Thumb drive |

|

|

Temperature |

0 ~ 40°C |

|

Wire Coiling Machines

Spring machines that specialize in compression springs. These machines have an automatic program function for easy production of compression springs and a function for making curved tapered shapes.

SH-3AG Wire Coiling Machine

SH-3AG Wire Coiling Machine

A high-speed, high-quality production system specialized in the processing of guide wires for medical catheters

2-Point Coiling Spring Machine for Guide Wires Processing

The newly developed 2-point coiling unit disperses friction during coiling and contributes to stabilization of the initial coil tension. Furthermore, compared to the 1-point method, the trace of the coil inner diameter is greatly reduced without an arbor.

Features:

Corresponds to the quality required for guide wires

-

Compared to the 1-point method, no arbor (core metal) is required, so the trace of the coil inner diameter is greatly reduced.

-

The rotary discharge shooter PR-1 that receives the optional long coil wire suppresses runout when manufacturing long coils, eliminates problems with the discharge method, and supports high-precision machining.

Supports automated production

Unlike the conventional winding production method, the automatic cutting ability machine after coiling enables continuous production of coils. This saves about 90% of labor in one day's work. In addition, the yield is improved because there is no extra waste material generated during production.

Supports high-speed production

Adjust the amount of wire feeding to keep the applied tension constant and feed it into the machine. As a result, in addition to stable high-quality processing, the production speed is about three times faster (according to our research) than the conventional winding production method.

Specifications:

|

Standard |

Wire Dia. 0.08~0.23mm |

Solenoid valves |

4pcs(8pcs at max) |

|---|---|---|---|

|

Outside Dia. 28mm or more |

Service air pressure |

Max 0.5 Mpa |

|

|

D/d 4 or more |

Power source |

AC 200V, 3-Phase, 15A |

|

|

Feed Axis |

Resolution 0.001mm |

Net weight |

838 lbs. |

|

Max. Speed 278ft/min |

Control device |

Windows |

|

|

Cut Axis |

Resolution 0.001° |

||

|

Torsion Attach Axis |

Resolution 0.001mm |

Display |

15.6'' Full HD touch screen |

|

Arbor Axis |

Resolution 0.001mm |

External memory |

USB thumb drive |

|

1st/2nd Point Axis |

Resolution 0.001mm |

Service Temp. |

41~104°F |

SF-1A Wire Coiling Machine

SF-1A Wire Coiling Machine

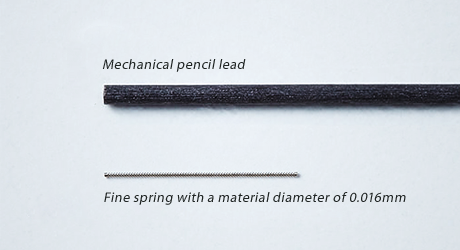

An ultra-thin wire coiling machine that can process wires thinner than 20 µm.

The SF-1A enables a feed roller diameter of 16 mm and an ultimate wire guide length of 6 mm to further expand the processing range of ultra-thin wire springs.

Features:

Dedicated MNO Program for Spring Production

-

Easy operations for quicker preparation.

-

High resolution for controlling the latest servo motors.

-

Allows varied control based on measurement results, such as the pitch, diameter, and bend angle.

-

Common program for both torsion machines and coiling machines.

-

Includes a motor sensor system.

-

Versatile production management screen and production data collection function.

Our mission to achieve the smallest coiling in the world.

-

Mec’s world-renowned ultra-thin wire machines have now evolved further.

-

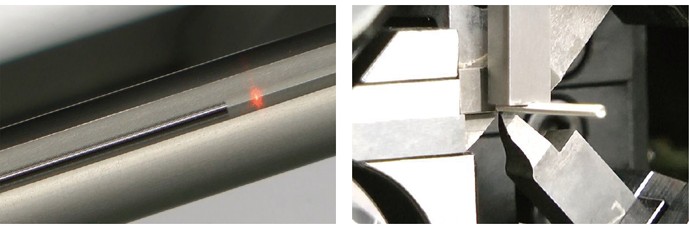

Ultra-thin wire coiling machine for wire diameters of 0.016 to 0.1 mm.

-

Enables a feed roller diameter of 16 mm and an ultimate wire guide length of 6 mm.

-

Equipped with 4 standard axes: feed, cut, pitch, and coil diameter.

-

An optional initial tension servo and arbor front-back servo can be added.

-

Uses a mechanism designed to assist ultra-fine adjustment.

-

Equipped with a standard ultra-high accuracy sensor (MSD-1) .

Coiling Mechanism

-

A specialist design for ultra-thin wires, with a feed roller diameter of 16 mm and a wire guide length of 6 mm.

-

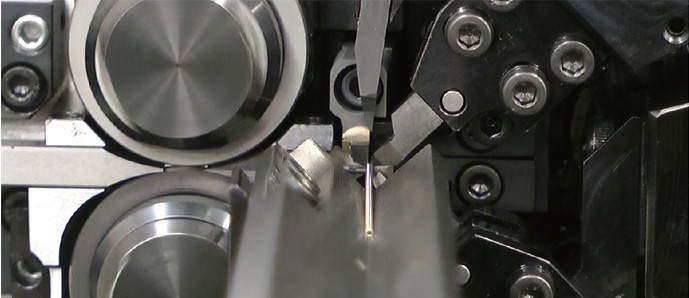

The cut tool and coiling point areas have been strengthened to provide both stability and adjustability.

-

Tools are attached using a standard mechanism for attaching wire guides with reference to the feed roller, and the newly developed pitch arbor unit can be moved up, down, left, and right to adjust the arbor position in relation to the wire guide.

Optional Equipment

-

Initial tension servo unit

-

Core forward/reverse servo unit

Specifications:

|

Capacity |

Wire Dia. 0.016 ~ 0.1mm |

Service air pressure |

Max. 0.5 MPa |

|---|---|---|---|

|

Outside Dia. 2mm |

Power source |

AC 200V 3-Phase, 15A |

|

|

Feed Axis |

Resolution 0.001mm |

Net weight |

400kg |

|

Cut Axis |

Resolution 0.001° |

Control device |

Max. 9-axis to be controlled by computer - OS Windows XP |

|

Pitch Axis |

Resolution 0.001mm |

||

|

Point Axis |

Resolution 0.001mm |

Display |

17'' TFT color LC Display |

|

Initial tension Axis(Option) |

Resolution 0.001mm |

External memory |

USB thumb drive |

|

Solenoid valves |

4pcs(Max 8pcs available) |

Service Temp. |

0~40℃ |

SH-3A Wire Coiling Machine

SH-3A Wire Coiling Machine

The SH-3A, a multi-functional coiling machine with 1-point coiling, torsion attachment, and an initial tension servo, has further evolved.

This coiling machine can now process an even greater range of torsion springs.

Features:

1-point coiling with a wire diameter of 0.08 to 0.3 mm

-

Equipped with 8 standard axes: feed, cut, pitch, point, torsion, initial tension, coil front-back, and MSD-1.

-

Easier setup and greater speed than previous models, as the cut axis and torsion axis are separated.

-

Suitable for high-speed production of ballpoint pen springs, torsion springs, and elliptical springs in addition to standard cylindrical springs.

-

Optional ultra-thin wire attachment can be used to coil springs with a diameter of 0.08 mm or less.

Dedicated MNO Program for Spring Production

-

Easy operations for quicker preparation.

-

High resolution for controlling the latest servo motors.

-

Compatible with compression spring creation programs based on line graphs.

-

Allows varied control based on measurement results, such as the pitch and diameter.

-

Common program for both torsion machines and coiling machines.

-

Includes a motor sensor system.

-

Versatile production management screen and production data collection function.

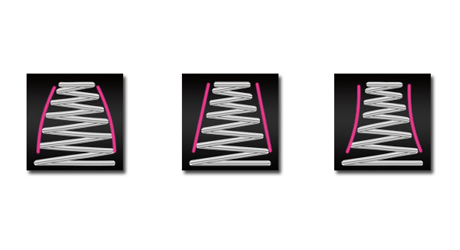

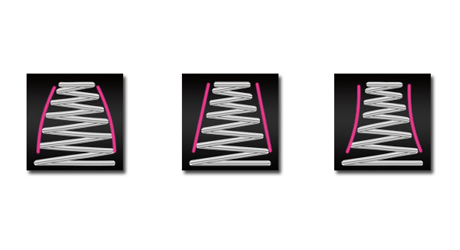

3 types of wire guides

The SH-3II has 3 wire guides with different lengths:

-

Short guide with a guide length of 23 mm.

-

Provides greater accuracy for short springs due to its shorter guide length, while retaining the same clearance length as a standard wire guide.

-

Standard wire guide with a guide length of 30 mm

-

Enables use of all tools available for the previous SH-3 wire guide.

-

Wire guide for ultra-thin wires with a guide length of 16 mm.

-

Enables coiling of wires with a diameter of 0.08 mm or less.

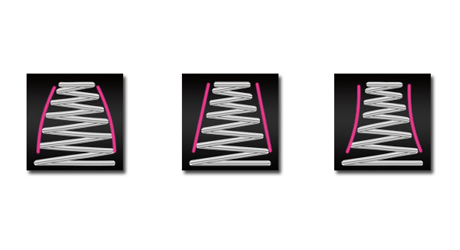

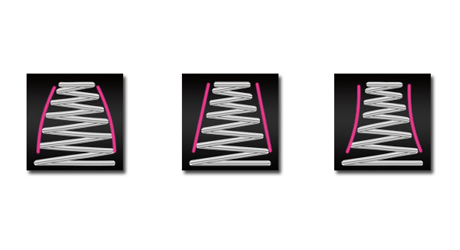

Taper synchronization constant

Enables the taper tilt to be managed with a value from 0 to 100. Suitable for load adjustment in addition to shape adjustment, as fine adjustment can be performed in 100 levels.

Optional Equipment

-

Ultra-thin wire attachment -3-dimensional bending servo unit to improve stability and speed when creating antenna springs

-

Capacitance level sensor

-

IS-1 shape detection unit with camera

Specifications:

|

Standard |

Wire Dia. 0.08~0.3mm |

Arbor Axis(Option) |

Resolution 0.001mm |

|---|---|---|---|

|

Outside Dia. 10mm |

Solenoid valves |

4pcs(Max 8pcs available) |

|

|

D/d 4 or more |

Air requirements |

Max 0.5 MPa |

|

|

Ultra Fine Wire A/T |

Wire Dia. 0.03 ~ 0.08mm |

Power source |

AC 200V 3-Phase, 15A |

|

Feed Axis |

Resolution 0.001mm |

Net weight |

400kg |

|

Cut Axis |

Resolution 0.001° |

Control device |

Max. 9-axis to be controlled by computer - OS Windows XP |

|

Pitch Axis |

Resolution 0.001mm |

||

|

Point Axis |

Resolution 0.001mm |

Display |

17'' TFT color LC Display |

|

Torsion A/T Axis |

Resolution 0.001° |

External memory |

USB thumb drive |

|

Initial tension Axis |

Resolution 0.001mm |

Service Temp. |

0~40 deg. C(32-104 deg .F) |

SH-8A Wire Coiling Machine

SH-8A Wire Coiling Machine

The SH-8A, our multifunctional coiling machine with 1-point coiling, torsion attachment, and an initial tension servo, has been fully revamped for greater operability and high-speed production.

Features:

1-point coiling machine with a wire diameter of 0.1 to 0.8 mm

-

Maximum outer coil diameter of 20 mm.

-

Equipped with 7 standard axes: feed, cut, pitch, point, torsion, initial tension, and MSD-1.

-

Optional core forward/reverse servo unit provided.

-

Easier setup and greater speed than previous models, as the cut axis and torsion axis are separated.

-

Suitable for high-speed production of torsion springs and elliptical springs in addition to standard cylindrical springs.

Dedicated MNO Program for Spring Production

-

Easy operations for quicker preparation.

-

High resolution for controlling the latest servo motors.

-

Compatible with compression spring creation programs based on line graphs.

-

Allows varied control based on measurement results, such as the pitch and diameter.

-

Common program for both torsion machines and coiling machines.

-

Includes a motor sensor system.

-

Versatile production management screen and production data collection function.

Taper synchronization constant

-

Enables the taper tilt to be managed with a value from 0 to 100.

-

Suitable for load adjustment in addition to shape adjustment, as fine adjustment can be performed in 100 levels.

Optional Equipment

-

Core forward/reverse servo unit

-

Slip sensor to detect slips in wire feeding

-

Capacitance level sensor

-

IS-1 shape detection unit with camera

Specifications:

|

Standard |

Wire Dia. 0.1~0.8mm |

Arbor Axis (Option) |

Resolution 0.001mm |

|---|---|---|---|

|

Outside Dia. 20mm |

Solenoid valves |

4pcs(Max 8pcs available) |

|

|

D/d 4 or more |

Service air pressure |

Max 0.5 MPa |

|

|

Feed Axis |

Resolution 0.001mm |

Power source |

AC 200V, 3-Phase, 16A |

|

Max. Speed 188m/min |

Net weight |

400kg |

|

|

Cut Axis |

Resolution 0.001° |

Control device |

Max. 9-axis to be controlled by computer - OS Windows XP |

|

Pitch Axis |

Resolution 0.001mm |

||

|

Point Axis |

Resolution 0.001mm |

Display |

17'' TFT color LC Display |

|

Torsion A/T Axis |

Resolution 0.001° |

External memory |

USB thumb drive |

|

Initial tension Axis |

Resolution 0.001mm |

Service Temp. |

0~40℃ |

WH-8A Wire Coiling Machine

WH-8A Wire Coiling Machine

A 5-axis, 2-point coiling machine with a maximum wire diameter of 0.8 mm and excellent cost-effectiveness.

The simple structure enables high-speed production and high accuracy in a reduced preparation time.

Features:

2-point coiling machine with a wire diameter of 0.2 to 0.8 mm

-

Maximum outer coil diameter of 28 mm

-

Equipped with 5 standard axes: feed, cut, wedge pitch, push pitch, and outside coil diameter.

-

An optional initial tension servo can be added.

-

Enables easy setup and high-speed production at a low cost.

-

Includes our newly-developed specialist MNO program for spring production, enabling simple and precise operations.

-

Features Mec’s world-renowned precision processing technology for ultra-thin wires.

-

The WH-8A also includes cutting-edge computer control technology.

Parts for 2-point mechanism

-

All fine-adjustment mechanisms have scale marks to improve reproducibility and ease of fine adjustment.

-

Cut operations use a crank mechanism to achieve high-speed production.

-

Coiling pin adjustment features an oscillating mechanism.

Dedicated MNO Program for Spring Production

-

Easy operations for quicker preparation.

-

High resolution for controlling the latest servo motors.

-

Compatible with compression spring creation programs based on line graphs.

-

Allows varied control based on measurement results, such as the pitch and diameter.

-

Common program for both torsion machines and coiling machines.

-

Includes a motor sensor system.

-

Versatile production management screen and production data collection function.

Taper synchronization constant

-

Enables the taper tilt to be managed with a value from 0 to 100.

-

Suitable for load adjustment in addition to shape adjustment, as fine adjustment can be performed in 100 levels.

Optional Equipment

-

Initial tension servo unit

-

Counterclockwise unit

-

Slip sensor to detect slips in wire feeding

-

MSD-1 sensor with servo motor to enable measurement of free length and outer diameter.

-

IS-1 shape detection unit with camera

Specifications:

|

Standard |

Wire Dia. 0.2~0.8mm |

Solenoid valves |

4pcs(8pcs at max) |

|---|---|---|---|

|

Outside Dia. 28mm or more |

Service air pressure |

Max 0.5 Mpa |

|

|

D/d 4 or more |

Power source |

AC 200V, 3-Phase, 16A |

|

|

Feed Axis |

Resolution 0.001mm |

Net weight |

400kg |

|

Max. Speed 118m/min |

Control device |

Max. 9-axis to be controlled by computer - OS Windows XP |

|

|

Cut Axis |

Resolution 0.001° |

||

|

Wedge/Pitch Axis |

Resolution 0.001mm |

Display |

17'' TFT color LC Display |

|

Push/Pitch Axis |

Resolution 0.001mm |

External memory |

USB thumb drive |

|

Point Axis |

Resolution 0.001mm |

Service Temp. |

0~40℃ |

WH-16 Wire Coiling Machine

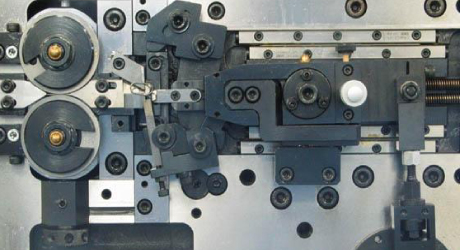

WH-16 Wire Coiling Machine

A 7-axis, 2-point coiling machine with a maximum wire diameter of 1.6 mm and excellent cost-effectiveness.

Equipped with a freely oscillating rotary cut as a standard feature for high-speed production and high accuracy in a reduced preparation time.

Features:

Dedicated MNO Program for Spring Production

-

Easy operations for quicker preparation.

-

High resolution for controlling the latest servo motors.

-

Compatible with compression spring creation programs based on line graphs.

-

Allows varied control based on measurement results, such as the pitch and diameter.

-

Common program for both torsion machines and coiling machines.

-

Includes a motor sensor system.

-

Versatile production management screen and production data collection function.

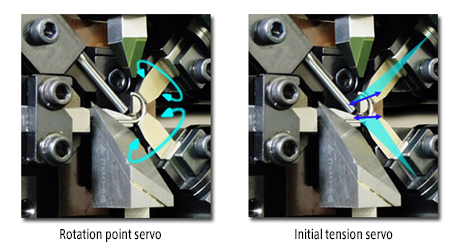

Newly-developed rotation point servo

-

Our new WH-16 point unit includes a rotating servo. Select the adjustment method of your choice (1st pin or 2nd pin can be selected).

-

You can also select a different servo for both the 1st pin and 2nd pin and use them in conjunction.

5-point coiling machine with a wire diameter of 0.5 to 1.6 mm

-

Enables easy setup and high-accuracy, high-speed production of springs.

-

The clockwise/counterclockwise direction can be switched simply by configuring a setting in the program.

-

An optional rotation point servo and initial tension servo can be added to the coiling point.

-

The alignment of the cut tool and core does not require readjustment after being decided once.

-

One-touch switching between oscillating cut and straight cut.

-

The oscillating cut bearing (oscillation) can be freely adjusted.

Taper synchronization constant

-

Enables the taper tilt to be managed with a value from 0 to 100.

-

Suitable for load adjustment in addition to shape adjustment, as fine adjustment can be performed in 100

Optional Equipment

-

Initial tension servo (tilting operations)

-

Rotation point servo (rotation operations)

-

IS-1 shape detection unit with camera

-

Slip sensor to detect wire slips

Specifications:

|

Standard |

Wire Dia. 0.5~1.6mm |

Solenoid valves |

4pcs(8pcs at max) |

|---|---|---|---|

|

Outside Dia. 50mm |

Service air pressure |

Max 0.5 MPa |

|

|

D/d 4 or more |

Power source |

AC 200V, 3-Phase, 25A |

|

|

Feed Axis |

Resolution 0.001mm |

Net weight |

900kg |

|

Max. Speed 165m/min |

Control device |

Max. 9-axis to be controlled by computer - OS Windows XP |

|

|

Cut Axis |

Resolution 0.001 deg |

||

|

Wedge-Pitch Axis |

Resolution 0.001mm |

Display |

17'' TFT color LC Display |

|

Point Axis × 2 |

Resolution 0.001mm |

External memory |

USB thumb drive |

|

Push-Pitch Axis |

Resolution 0.001mm |

Service Temp. |

0~40℃ |

|

Arbor Axis |

Resolution 0.01 deg |

|

|

WH-26 Wire Coiling Machine

WH-26 Wire Coiling Machine

An 8-axis, 2-point coiling machine with a maximum wire diameter of 2.6 mm and excellent cost-effectiveness.

Equipped with an oscillating cut as a standard feature, along with a center base mechanism that eliminates the need for cut readjustment when the coil diameter is changed.

Features:

2-point coiling mechanism

-

Enables easy setup and high-accuracy, high-speed production of springs.

-

The clockwise/counterclockwise direction can be switched simply by configuring a setting in the program.

-

An optional rotation point servo and initial tension servo can be added to the coiling point.

-

The alignment of the cut tool and core does not require readjustment after being decided once.

-

One-touch switching between oscillating cut and straight cut.

-

The oscillating cut bearing (oscillation) can be freely adjusted.

-

An optional slip sensor is provided for detecting slips when feeding.

-

Includes our newly-developed specialist MNO program for spring production, enabling simple and precise operations.

Taper synchronization constant

-

Enables the taper tilt to be managed with a value from 0 to 100.

-

Suitable for load adjustment in addition to shape adjustment, as fine adjustment can be performed in 100 levels.

2-point coiling machine with a wire diameter of 0.6 to 2.6 mm

-

Enables easy setup and high-accuracy, high-speed production of springs.

-

The clockwise/counterclockwise direction can be switched simply by configuring a setting in the program.

-

The alignment of the cut tool and core does not require readjustment after being decided once.

-

One-touch switching between oscillating cut and straight cut.

-

The oscillating cut bearing (oscillation) can be freely adjusted.

-

An optional slip sensor is provided for detecting slips when feeding.

-

Includes our newly-developed specialist MNO program for spring production, enabling simple and precise operations.

Advanced cut slide function

-

The alignment of the cut tool and core does not require readjustment after being decided once.

-

As the cut slide and core slide are both located on the center slide, the positional relationship of the two tools does not change, meaning that readjustment is not required.

-

The cutting method can be changed. You can easily switch between oscillating cut and straight cut.

-

The oscillating cut bearing (oscillation) can be adjusted. Adjust the bearing using the eccentric pin on the slide.

Dedicated MNO Program for Spring Production

-

Easy operations for quicker preparation.

-

High resolution for controlling the latest servo motors.

-

Compatible with compression spring creation programs based on line graphs.

-

Allows varied control based on measurement results, such as the pitch and diameter.

-

Common program for both torsion machines and coiling machines.

-

Includes a motor sensor system.

-

Versatile production management screen and production data collection function.

Specifications:

|

Capacity |

Wire Dia. 0.6~2.6mm |

Arbor Axis |

Resolution 0.001mm |

|---|---|---|---|

|

Outside Dia. 70mm |

Solenoid valves |

4pcs(8pcs at max) |

|

|

D/d 4 or more |

Service air pressure |

Max 0.5 Mpa |

|

|

Feed Axis |

Resolution 0.001mm |

Power source |

AC 200V, 3-Phase, 20A |

|

Max. Speed 102m/min |

Net weight |

1,400kg |

|

|

Cut Axis |

Resolution 0.001° |

Control device |

Max. 9-axis to be controlled by computer - OS Windows XP |

|

Wedge-Pitch Axis |

Resolution 0.001mm |

||

|

Upper/Lower Point Axis × 2 |

Resolution 0.001mm |

Display |

17'' TFT color LC Display |

|

Point Center Axis |

Resolution 0.001mm |

External memory |

USB thumb drive |

|

Push-Pitch Axis |

Resolution 0.001mm |

Service Temp. |

0~40℃ |