Sigma Presse, Innovative, Robust, Energy Efficient Servo and Conventional Hydraulic Press Technology

SIGMA PRESSE designs and manufactures innovative, reliable, energy efficient conventional and servo hydraulic presses, with tonnages up to 50,000 kN (5,000 tons). Every press we build is a close collaboration between our customers and our engineering and designers. Our design team made up of experienced, knowledgeable staff, many of whom have careers spanning over thirty years.

We have extensive background in both standard and special hydraulic presses for a wide array of manufacturing needs. Designs are based on the specific needs of the customers and throughout all phases of each project our technical staff constantly monitors each step to ensure that strict adherence to our quality control process is met. This attention to detail ensures that your machine will provide the productivity, reliability, and strength necessary meet your needs for years to come.

Servo Presses - Save Energy

SIGMA PRESSE is strongly motivated in the search for new applications, in particular it is following an ENERGY SAVE program, studying and manufacturing servo presses with high energy efficiency hydraulic systems, which allow the final user, in his production cycle, to reduce the energy consumption from 40% to 60% compared to a traditional hydraulic system also allows a considerable reduction of noise, obtaining better accelerations and speeds. The ENERGY SAVE system almost completely eliminates the overheating of the hydraulic oil and therefore reduces its deterioration, as well as saving energy by reducing heat.

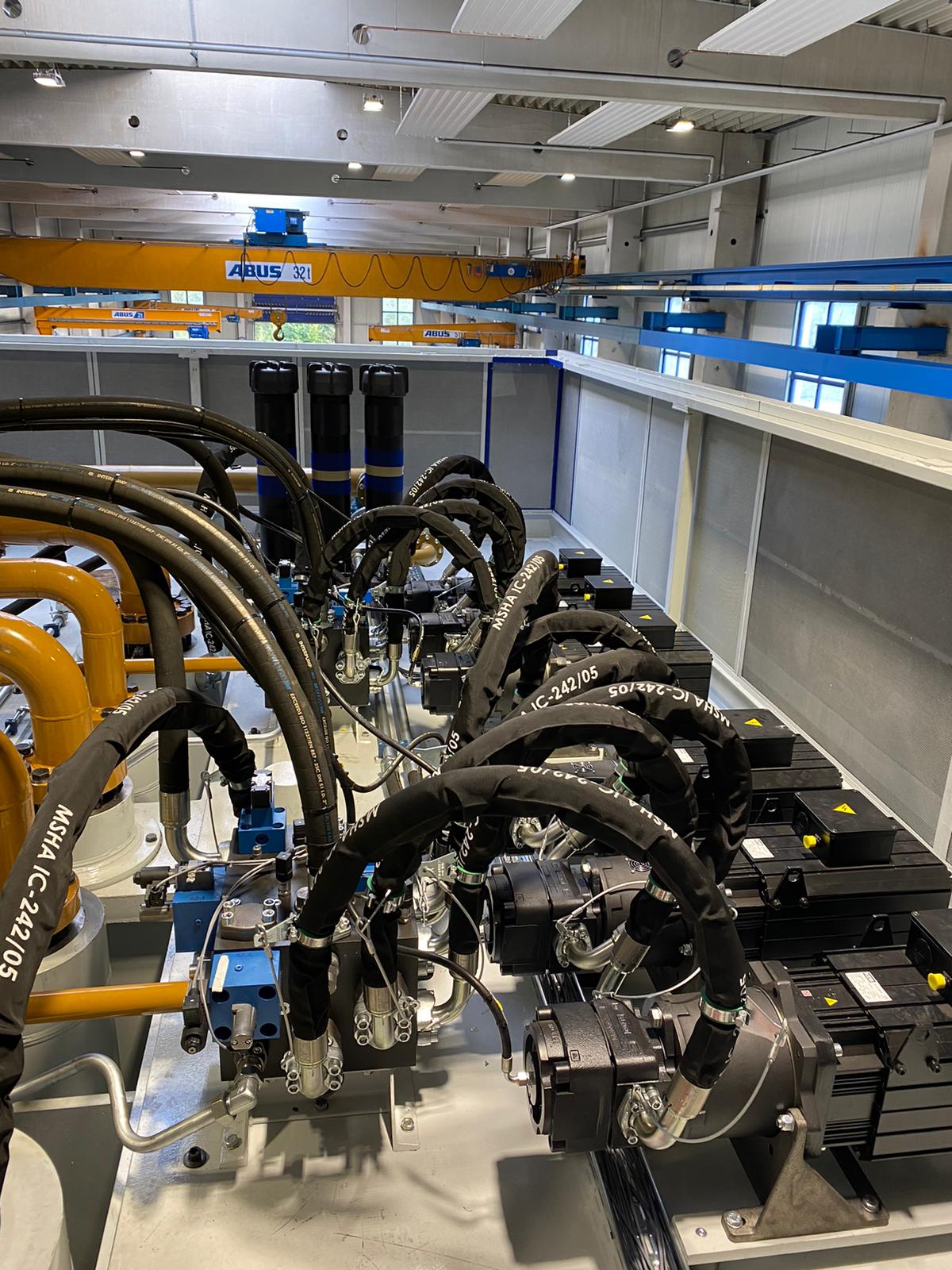

One of our recent builds

Conventional & Servo Hydraulic Presses

Hydraulic presses for automotive

The presses for automotive are made from 1.000 kN to 50.000 kN (100 Ton to 5.000 Ton) for sheet metal stamping, heat shield molding, SMC, RTM and PCM, Forged carbon, composite materials that need molds with high temperatures 160 ° -250 °. All presses are equipped on request with mold loading and unloading, with the possibility of installing an automatic bolster for mold change, lower and upper blank holder.

Hydraulic Presses for Gaskets

Gasket presses are machines made with different tonnage, from 1,000 KN to 50,000 KN, aimed at industrial sectors such as the chemical and oil sectors. . These gasket presses can be equipped with automatic bolster for mold change, hot plates, vacuum bell and central and side extractors. They can also be equipped with an intermediate floor that allows for double production. Gasket presses include PTFE, FILLED PTFE, PEEK, MELAMINE, POM, SMC GLASS FIBER, SMC CARBON FIBER molding. It is also foreseen the molding of special gaskets, inserts for ball valves, sealing rings, phenolic and urea materials, etc …

Hydraulic presses for pipe calibration

The presses for the calibration of pipes have dimensions from 10,000 kN to 50,000 kN. The function of these presses is to calibrate welded tubes, cold formed and obtained from sheet metal, which can be in carbon steel, stainless steel, duplex, super duplex and chromium steel. The pipes are used in oil & gas plants. The dimensions of the presses vary according to the size of the tubes to be processed: from 8 ”to 72” with a diameter of 1,828.8 mm. The presses for pipe calibration can have an automatic system with advance shuttle during the pipe calibration process. It is possible to install an automatic system for changing the mold. We manufacture sizing presses for stainless steel, X70, Duplex, Superduplex pipes up to 70 mm thick.

Hydraulic presses for sheet metal

The presses for stamping sheet metal are made on tonnages from 2,000 kN to 50,000 kN and are used for sheet metal deformation, pre-bending and bending. The sheet metal can be of various materials, not only iron, but also carbon steel, stainless steel, duplex, super duplex and chromium steel. It is possible to install an automatic mold change system, lower and upper blank holder and automatic blocking of the molds. The presses meet fundamental criteria such as sturdiness, precision and finish. We also produce “yawn” mold testing presses.

Hydraulic presses for deep drawing

The deep drawing presses are made for tonnages from 2,000 kN to 50,000 kN with the possibility of installing an automatic bolster for mold change, lower and upper blank holder. The deep drawing presses are made with high quality software able to manage the lower and upper blank holder and the re-drawing and deep drawing system from the bottom with lower and upper extractor, with a system of shock absorbers for sheet metal shearing, which allow to deform the sheet and obtain objects of various shapes.

Hydraulic presses for SMC and Composite Materials

The presses for SMC – SMC CARBON – RTM – PCM and FORGED CARBON are used for the automotive and solar energy sector. We manufacture such presses up to 50,000 kN (5,000 Ton). We can also integrate in these presses the power system for the electric heating of the molds, including the automatic control of the temperatures in various areas of the mold and with powers of various Kw.

Hydraulic presses for forging

Forging presses first process hot, temperature, and high-speed material to allow for the forging of a piece of steel. The forging press can reach 120 – 140 cycles per minute. It is manufactured for tonnages from 10,000 kN to 50,000 kN (1000 Ton to 5000 Ton).

Electric Presses

SIGMA PRESSE Ltd produces electric screw presses with inverters in full respect of nature. The presses provide for the possibility of adjusting the speed and position of the slide in real time and with exceptional precision. The free cycle mode allows to emulate the functions of hydraulic presses. The electric presses, unlike the hydraulic ones, do not use oil. The electric press is a mechanical press capable of adapting to all forming needs, from coining to deep drawing.