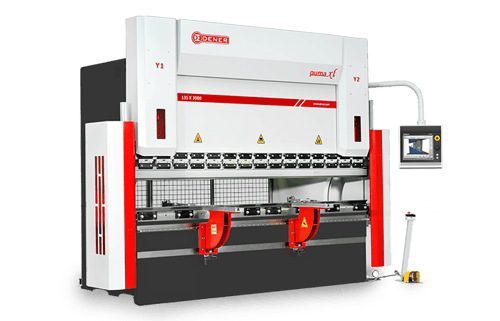

Dener SMART XL CNC economical, stronger, faster accurate new model. Smart XL Press brake targets small and medium size sheet metal working companies. The most important features of Dener Smart XL are; faster working speeds, higher bending power , deeper throat depth, higher stroke and daylight,

Dener Smart XL CNC is a synchronized hydraulic press brake with numerical CNC controllers. It offers simple operation, quick and easy part programming, easy setup of the machine, auto calculation of the bend angle, and back gauge correction. 2D offline programming feature which comes with ESA 630 Controller gives possibility to end users to complete bending program on Office PC and transfer to machine by LAN or USB. These functions make Dener Smart XL CNC Hydraulic Press Brake very popular among users. Dener Smart machine has more advanced futures than its competitors. Some of these features are: a strong and complete mono block welded frame, longer stroke and longer distance between frames, deeper throat depth, and a higher working table.

Standard Equipment

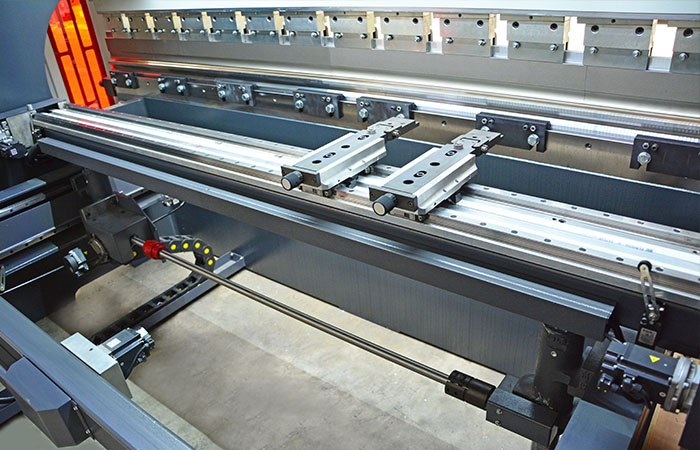

• Y1, Y2, X, R Axis

• European type punch holder

• European type die holder

• 10″ Esa S 630 touch screen 2D control unit

• Deeper Throat Depths (450 mm)

• Higher Stroke and Longer Daylight (350 mm)

• Hoerbiger or Rexroth hydraulic system

• Foot pedal with emergency stop button

• Linear Guided Front Support Arms

• Side and back safety gates

Optional Equipment

• Delem Da 52 Control unit

• Cybelec Cybtouch 10 Control unit

• X and R Backgauge

• Quick tool change system

• Manual crowning

• CNC crowning

• Light curtain with CE norm

• Multi V Die

• Hydraulic Oil Cooling System

• Electrical Cabinet Cooling System

• Wila mechanic Tool Holding System

• Wila hydraulic Tool Holding System