Specialty Sanding And Finishing Machines

Machines Constructed to Handle an Array of Specialized Materials And Applications

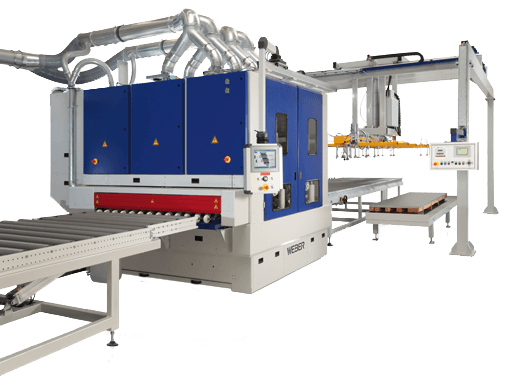

WEBER TTK

Deburring machine for coated sheets

In the production of large generators, the definitive output is not certain until after the final completion. To realise the highest possible efficiency, perfectly, flawless coated sheets are the main prerequisite. WEBER fulfils this prerequisite with the TTK.

WEBER TTK Technical Data

|

Working widths 1350 and 1600 mm |

Grinding belt length 1900 mm |

|

Working height 900 mm (constant) |

Grinding belt drive up to 22 kW |

|

Version with 1 to 2 grinding stations |

Multi Panel TP900 Comfort |

|

Workpiece thickness 0.2-3.0 mm |

“i-Touch” controller |

|

Infinitely variable feed speed |

Freely selectable arrangement |

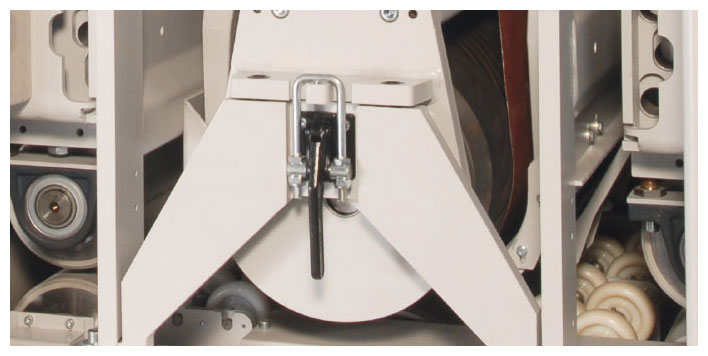

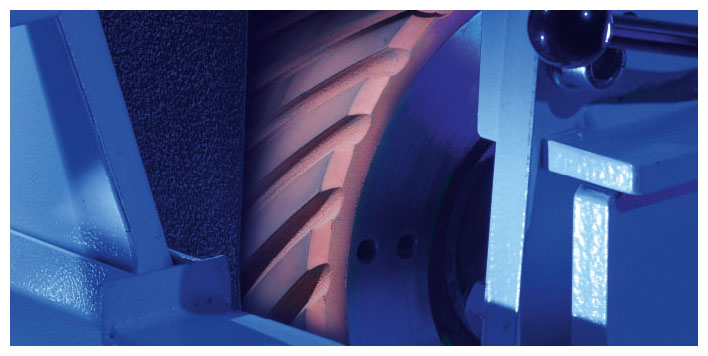

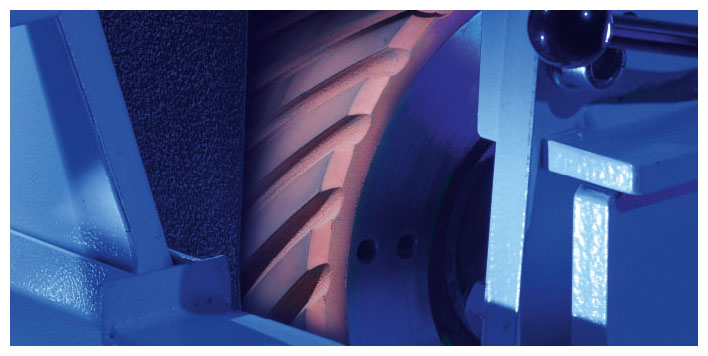

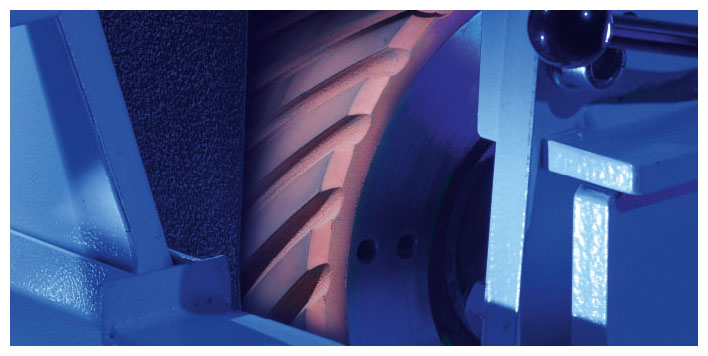

TTK Principal

TTK Functional principle

The distinctive feature of the WEBER TTK: our own in-house developed dressing unit for the deburring of coated sheets. This innovation enables deburring and grinding results, which totally satisfy all requirements of the generator manufacturer – without additional expense for the coated sheet manufacturer.

TTK Dressing

TTK Dressing Unit

A dressing unit, which was specially designed by WEBER for this application, prepares the grinding belt. Handling this is very simple: the belt needs only to be put on to the grinding head, the automatic mode takes care of the rest. The grinding belt can be changed quickly in just a few steps by a single person. Thanks to WEBER technology, the grinding belt lasts several weeks.

WEBER NLCA

Wet deburring machine for fine-blanking parts Our solution for the automotive industry

The WEBER NLCA is a deburring machine especially for fine-blanking parts, which require strong, even edge rounding at higher throughput speeds. The combination with the WEBER cleaning machines in compact design enables the highest degree of production efficiency in the smallest space.

WEBER NLCA Technical Data

|

Working width 600 mm |

Grinding belt length 2620 mm |

|

Working height 900 mm (constant) |

Grinding belt drive up to 30 kW |

|

Version with 1 to 6 machining stations per frame unit |

Multi Panel MP 377 |

|

Mode of operation: top grinding |

“i-Touch” controller |

|

Workpiece thickness 0.3-120 mm |

Freely selectable arrangement |

|

Infinitely variable feed speed (1-10 m/min) |

|

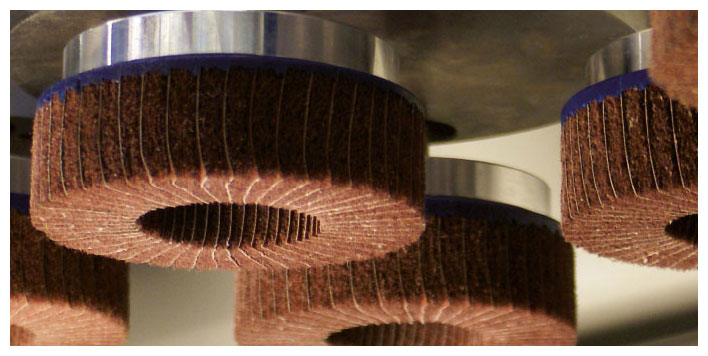

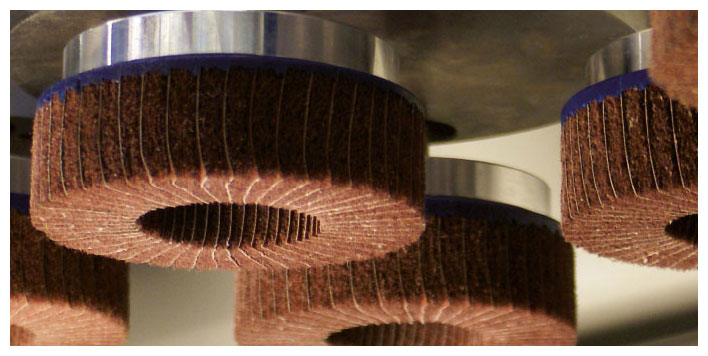

Grinding Roller

WEBER GD Grinding roller

For surface finishing, WEBER uses its GD grinding roller: A perfect surface finish and ideal deburring are achieved in a single operating sequence. The grinding pressure is generated by positioning the roller downwards below the zero level. When the roller approaches the workpieces, the rubber coating of the roller is pushed inwards. The restoring force of the roller is thus the grinding force. Grinding rollers are available with different diameters and rubber hardness and can be adapted to all parts to be ground.

Planetary Head

WEBER DR Planetary head

For surface finishing, WEBER uses its GD grinding roller: A perfect surface finish and ideal deburring are achieved in a single operating sequence. The grinding pressure is generated by positioning the roller downwards below the zero level. When the roller approaches the workpieces, the rubber coating of the roller is pushed inwards. The restoring force of the roller is thus the grinding force. Grinding rollers are available with different diameters and rubber hardness and can be adapted to all parts to be ground.

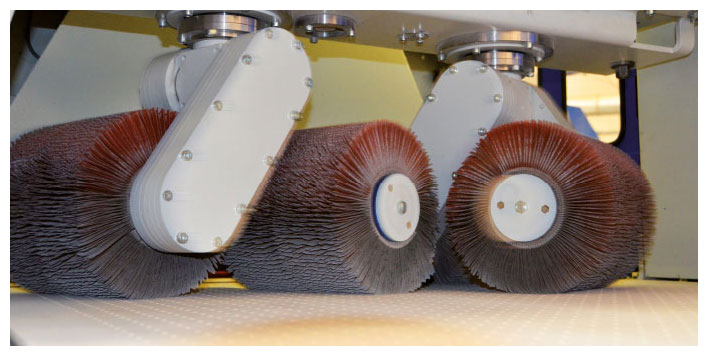

Brush Rollers

WEBER BS Brush rollers

The BS brush rollers are used for removing secondary burrs after grinding or milling. They machine the surface and to some extent the edges. For system-related reasons, the rounding action is much more effective on the transverse edges than on the longitudinal edges that are barely rounded. The BS brush rollers improve the surface quality, change the surface roughness or surface structure. They also make it possible to remove material residue after grinding or milling without damaging the surface.

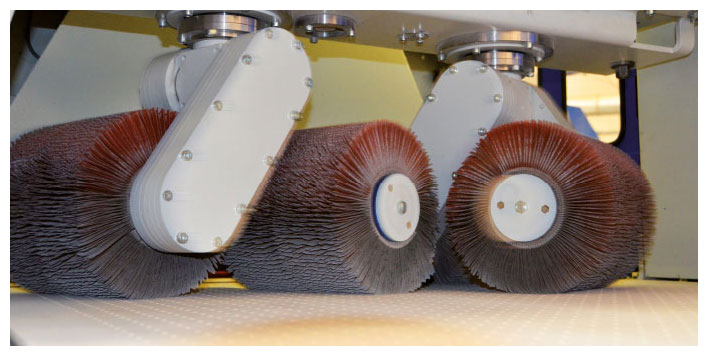

Brush System

WEBER MRB Brush system

When round brushes are used, several rotating heads are also arranged next to each other. The meshing of the brushes during the combing procedure and two brushes per head create even machining results along the entire operating width. The modular design of the brush heads allows for problem-free machining of each part with the procedure it requires. This arrangement works perfectly for any material thickness starting from one millimeter.

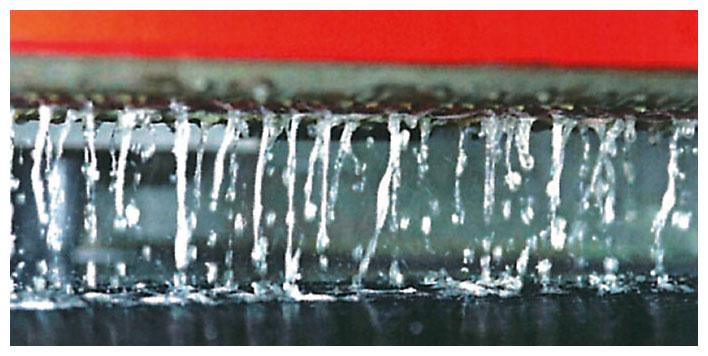

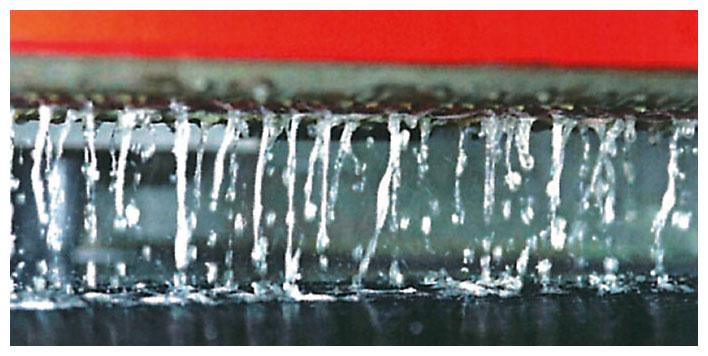

Wet Grinding

WEBER Wet grinding technology

Our many years of experience and sophisticated technology make WEBER‘s wet-grinding systems our customers‘ first choice. Our time-tested technology creates first-class results. In addition, WEBER‘s special focus is on the cost-effective and environment-friendly design of our systems. The cleaning systems required for the grinding fluid are highly economical to operate and stand out due to their simple operation, cleaning and maintenance.

WEBER TNA

Compact wet deburring for fine blanking parts

The WEBER TNA is a fully automatic 4-shift operation deburring machine specifically for fine-blanking parts to offer a cost-efficient option for deburring, rounding or for processing the secondary burr as a downstream machine for surface grinding. As the "compact sister" of the successful WEBER NLCA, this series is a space-saving model with the highest quality.

WEBER TNA Technical Data

|

Working width 300 mm |

Grinding belt length 2620 mm |

|

Working height 1000 mm (constant) |

Grinding belt drive up to 30 kW |

|

Version with 1 to 2 machining stations per frame unit |

Multi Panel |

|

Mode of operation: top grinding |

“i-Touch” controller |

|

Workpiece thickness 0.3-40 mm |

Freely selectable arrangement |

|

Infinitely variable feed speed (0.5 - 10 m/min) |

|

Grinding Roller

WEBER GD Grinding roller

For surface finishing, WEBER uses its GD grinding roller: A perfect surface finish and ideal deburring are achieved in a single operating sequence. The grinding pressure is generated by positioning the roller downwards below the zero level. When the roller approaches the workpieces, the rubber coating of the roller is pushed inwards. The restoring force of the roller is thus the grinding force. Grinding rollers are available with different diameters and rubber hardness and can be adapted to all parts to be ground.

Planetary Head

WEBER DR Planetary head

WEBER uses its planetary head technology for all-round edge machining with cup brushes. In this process, several rotating brushes arranged in groups are given an additional turning motion. This means that the brushes work at the ideal angle on the workpiece. In the patented WEBER solution, the tools of adjacent heads overlap in a way that ensures that there are no gaps during machining. As an alternative, we at WEBER also construct a two-row arrangement in which each tool carrier is equipped with six brushes.

Brush Rollers

WEBER BS Brush rollers

The BS brush rollers are used for removing secondary burrs after grinding or milling. They machine the surface and to some extent the edges. For system-related reasons, the rounding action is much more effective on the transverse edges than on the longitudinal edges that are barely rounded. The BS brush rollers improve the surface quality, change the surface roughness or surface structure. They also make it possible to remove material residue after grinding or milling without damaging the surface.

Brush System

WEBER MRB Brush system

When round brushes are used, several rotating heads are also arranged next to each other. The meshing of the brushes during the combing procedure and two brushes per head create even machining results along the entire operating width. The modular design of the brush heads allows for problem-free machining of each part with the procedure it requires. This arrangement works perfectly for any material thickness starting from one millimeter.

Wet Grinding

WEBER Wet grinding technology

Our many years of experience and sophisticated technology make WEBER‘s wet-grinding systems our customers‘ first choice. Our time-tested technology creates first-class results. In addition, WEBER‘s special focus is on the cost-effective and environment-friendly design of our systems. The cleaning systems required for the grinding fluid are highly economical to operate and stand out due to their simple operation, cleaning and maintenance.

WEBER M

Surface finish for metal coils and metal sheets

The creation of brushing and grinding patterns on high quality metal sheets is a science in itself. With its series M, WEBER has developed a machine that creates such perfect grinding patterns that nothing is left to be desired. When necessary, even fully automatically.

WEBER M Technical Data

|

Working widths 1100, 1350, 1600 & 2000 mm |

Grinding belt length 2620 mm |

|

Working height 850 mm (constant) |

Grinding belt drive up to 75 kW |

|

1 to 2 machining stations per frame unit |

Multi Panel |

|

Workpiece thickness 0.5–25 mm |

“i-Touch” controller |

|

Infinitely variable feed speed (3–25 m/min) |

Freely selectable arrangement |

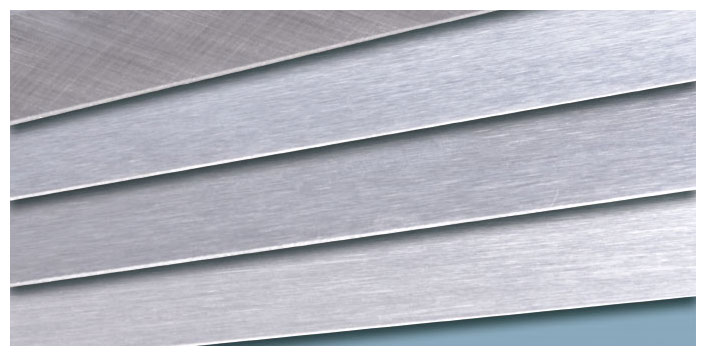

Grinding Pattern

M Grinding patterns

The WEBER M creates a sophisticated surface finish for high-end products. Whether short line, long line or duplo finish – the number of variations is virtually unlimited. It is a matter of course that this is achieved with absolutely consistent WEBER quality.

Grinding Roller

WEBER GD Grinding roller

For surface finishing, WEBER uses its GD grinding roller: A perfect surface finish and ideal deburring are achieved in a single operating sequence. The grinding pressure is generated by positioning the roller downwards below the zero level. When the roller approaches the workpieces, the rubber coating of the roller is pushed inwards. The restoring force of the roller is thus the grinding force. Grinding rollers are available with different diameters and rubber hardness and can be adapted to all parts to be ground.

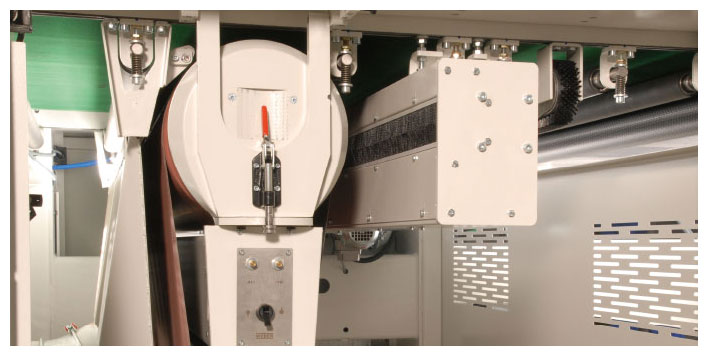

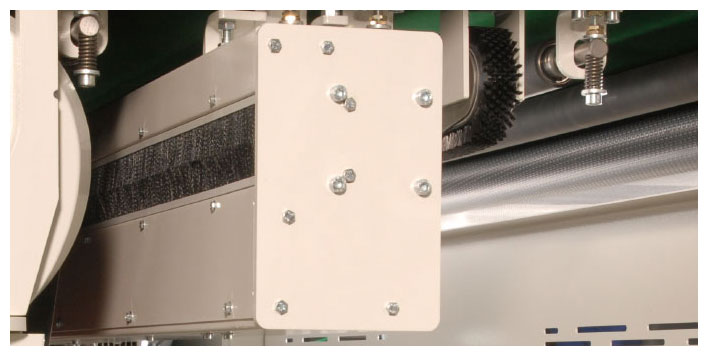

Grinding Beam

M-CBF Grinding beams

The patented WEBER CBF system presses the grinding belt against the workpiece via a segmented grinding beam. In this way, diverse grinding patterns are possible with an easily adjustable line length. Even machining thicker metal sheets is no problem for this system – and it is all accomplished with a longer grinding belt service life and lower material heating.

Brush Rollers

WEBER BS Brush rollers

The BS brush rollers are used for removing secondary burrs after grinding or milling. They machine the surface and to some extent the edges. For system-related reasons, the rounding action is much more effective on the transverse edges than on the longitudinal edges that are barely rounded. The BS brush rollers improve the surface quality, change the surface roughness or surface structure. They also make it possible to remove material residue after grinding or milling without damaging the surface.

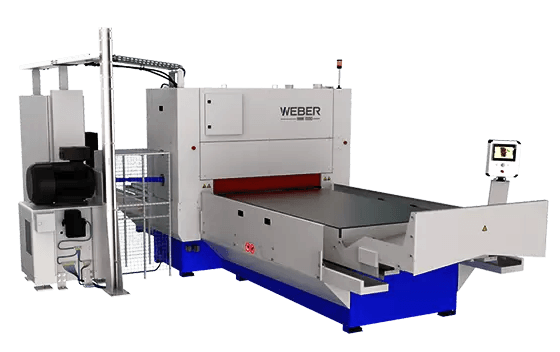

WEBER MNR

Precision calibration for high-end sheet metal

Creating plane-parallel, high-quality sheet metal is a science in itself. With the MNR series, WEBER has developed a machine that produces perfect micrographs. The WEBER MNR with reversible table offers the higest precision.

WEBER MNR Technical Data

|

Working widths 1100, 1350, 1600 & 2000 mm |

Grinding belt length 2620 mm |

|

Working height 1000 mm (constant) |

Grinding belt drive up to 110 kW |

|

1 to 2 machining stations per frame unit |

Multi Panel |

|

Workpiece thickness 0.5–25 mm |

“i-Touch” controller |

|

Infinitely variable feed speed (3–25 m/min) |

Freely selectable arrangement |

Grinding Pattern

M Grinding patterns

The WEBER M creates a sophisticated surface finish for high-end products. Whether short line, long line or duplo finish – the number of variations is virtually unlimited. It is a matter of course that this is achieved with absolutely consistent WEBER quality.

Grinding Rollers

M-GD Grinding rollers

The WEBER M-GD grinding roller is process-controlled pressed against the workpiece, and thus creates a perfect grinding pattern of absolutely consistent, best quality. The grinding operation is controlled by the leading edge and trailing edge. This prevents damage to the grinding belt, thus lengthening the service life of the grinding belt and further increasing the efficiency of the machine.

Grinding Beam

M-CBF Grinding beams

The patented WEBER CBF system presses the grinding belt against the workpiece via a segmented grinding beam. In this way, diverse grinding patterns are possible with an easily adjustable line length. Even machining thicker metal sheets is no problem for this system – and it is all accomplished with a longer grinding belt service life and lower material heating.

Brush Rollers

M-BS Brush rollers

The secret of the WEBER M: the newly developed oscillating brush system M-BS creates every imaginable brush pattern. Up to 2000 strokes per minute enables the duplo finish (grinding and brushing) in just one pass. And that at extremely high feed speeds. The system operates extremely uniformly – fluctuations in quality are thus a thing of the past.