For over Four decades, Universal Feed and Machine (UFM) has been committed to designing and building premium quality, high performance automated press feeding systems and equipment.

In 1969, UFM started building air feeds, coil cradles, coil reels and powered straighteners. Over the years we have developed significant and diverse systems to automate press feed and coil handling systems. These include servo roll feeds, coil cars, coil storage racks, coil up enders, Space Saving coil handling systems, servo driven zig zag feed systems, push-pull servo feeds, Cut-To-Length systems and much more.

The staff at Universal Feed and Machine has decades of experience in equipment design and construction of precision machinery, sales and service. An experienced parts department services any replacement part need - in most cases, on the same day. Our 24/7 technical support is as close as your telephone.

Let us the Universal Feed and Machine Team help you solve and increase productivity. We are experienced at building lines that conserve precious floor space, lines for very heavy gauge and/or high strength steel and versatile conventional lines that work with Class A and other surface-critical materials. We trust you will come to agree that Universal Feed and Machine is SMART. TOUGH. PROVEN.

Universal Feed & Machine is a leader in American made coil handling solutions!

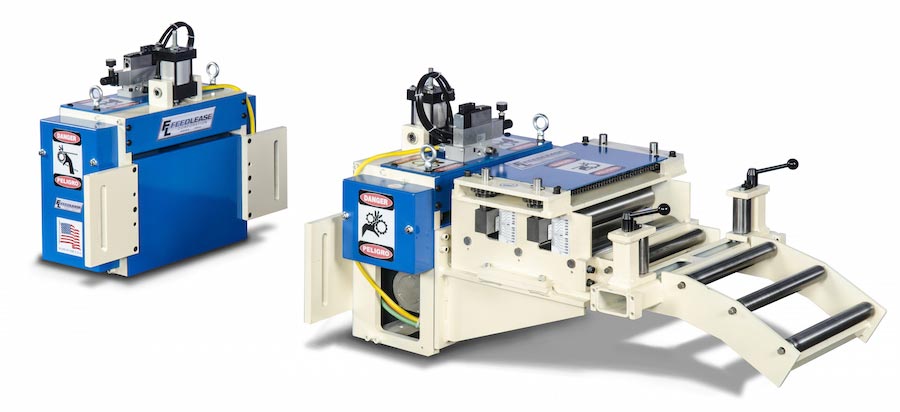

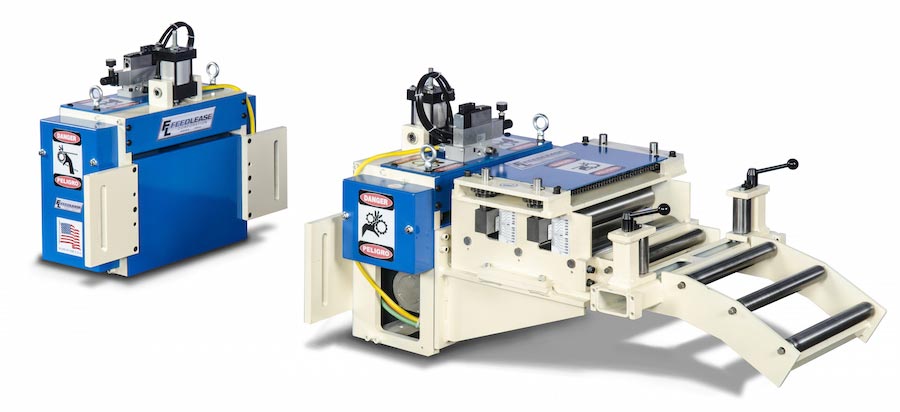

Push Pull Servo Driven Roll Feeds

The RF Series

The RF Series feeds are ideal for medium to heavy duty stamping and cut-to-length applications. This series comes in six sizes, ranging from 2.5" to 8" diameter feed rolls in an array of coil widths. High torque servo motors that drive either planetary or helical-bevel reducers make the RF series both powerful and precise.

RF-2.5 Series Servo Feeds

RF-2.5 Series servo feeds are designed to provide an economical means of employing servo feed technology on smaller presses without sacrificing quality, accuracy, durability or power.

The mechanical design of the RF-2.5 Series sets it apart. Consider the standard features on every model: Maintenance-Free AC brushless servo motor; a Kevlar non-stretch timing belt transfers power to the feed rolls; solid, full width, matte finish feed rolls; adjustable stroke air cylinder for roll pressure and pilot release; pivoting upper roll assembly maintains full gear mesh at any thickness; heavy duty, “C” frame, Slide & Clamp edge guide; slotted press mounting plate; entrance curve section and remote jog pendant with four modes.

Featured Videos

RFZZ-3-24 Zig-Zag Roll Feed

Material Support Table

All RF-2.5 Series servo feeds can be equipped with an optional, adjustable height cabinet base.

All RF Series servo are available in a Push-Pull configuration and operate synchronously from a single control.

Designed for blanking out diameters, zig/zag servo feeds can be programmed to perform from two to multiple out blanks, typically saving at least 8% in material costs.

Servo Feed Specifications

RF 2.5 Series

Model RF-2.5 (63.5)Width (in/mm) |

CapacityFull Width (in/mm) |

CapacityWith PTS (in/mm) |

|---|---|---|

6 / 152.4 |

0.187 / 4.75 |

0.120 / 3.05 |

12 / 305 |

0.156 / 3.96 |

0.105 / 2.67 |

18 / 458 |

0.125 / 3.18 |

0.080 / 2.03 |

24 / 610 |

0.094 / 2.39 |

0.060 / 1.52 |

30 / 762 |

0.063 / 1.60 |

0.035 / 0.89 |

Ratings are for mild steel |

||

-

Standard Features

-

Optional Features

-

Remote jog with jog-to-length

-

Entrance curve section for material support

-

Heavy-duty, slide & clamp edge guides

-

Color Touch screen operator interface

-

200 job memory

-

On-the-fly, micro adjust feature

-

English/Spanish, Inch/Metric

-

Batch counter

RF Series Servo Feeds

The exceptional mechanical design of the RF Series sets it apart from many other feed designs. Horizontal tie-bars provide significant structural rigidity. Feed rolls are full diameter across the entire rated width of the feed. Sealed-for-life spherical roller bearings are used to support the feed rolls.

All RF Series feeds can be equipped with a pull-thru straightener.

The rolls raise and lower on a pivot, rather than up and down in a slide block, to ensure full gear mesh regardless of the thickness of the material.

The roll pressure is applied by two adjustable-stroke pneumatic cylinders. Roll pressure is adjusted by a supplied regulator. The same cylinders are also used for the pilot release of the upper feed roll. These cylinders are positioned well past the center point of the rolls to provide leverage for optimum pressure to the roll.

-

Standard Features

-

Optional Features

-

Adjustable height cabinet (optional on RF-2.5 and RF 3)

-

Remote jog pendant with jog-to-length

-

Curve section or chute support bracket

-

Heavy-duty adjustable entry guides

-

Color touch screen Operator

-

200 Job Memory

-

On-the-fly, micro-adjust feature

-

English/Spanish, Inch/Metric

-

Feed complete output

-

Batch counter

Servo Feed Controls Universal Feed and Machine Corporation is proud to employ top quality controls on every servo feed. Universal Feed and Machine servo feeds utilize, as standard, a Control Techniques (Emerson) drive for superior performance. Since no components of the electronic system are proprietary, our customers have the option of using their local distributor for any replacement parts. Optional I/O are available for more advanced systems. For example, our optional Line Automation allows any powered axis to be stored in the job recipe and automatically set to position when a given job is loaded.

1000 Series control, standard on RF 2.5 and RF 3 models, with color touch screen operator interface.

5000 Series control, standard on all RF 4 through RF 8 models, with color touch screen operator interface.

-

Standard Features

-

Optional Features

-

Brushless servo motors

-

Servo feeds up to 150 HP

-

Jog forward/reverse - Slow/Fast

-

Jog-to-length - Slow/Fast

-

Auto/Manual mode

-

Serial interface available

-

Feed complete output (optional on RF 2.5 and RF 3 Series)

-

200 recipe storage

-

Color touch screen operator interface

-

Micro adjust plus/minus

-

Setup mode password protection

-

Feed length to 0 to 999.999

-

Batch and part count

-

Press too fast fault

-

E-Stop

Dual Roll Vertical Guides

"No Tools Required" Passline Height Adjustment

Hand Crank Adjustable Vertical Guides

Floor Stand with Guide Bars

Motorized Vertical Guides

Anti-Back-up Rolls

Pull-Through Straightener

Material Support Table

Heavy Duty Pull-Thru Straightener With Pilot Release

RF Series

Width (in/mm) |

RF 3CapacityFull Width |

RF 3CapacityWith PTS |

RF 4Capacity FullWidth 4 / 101 |

RF 5Capacity FullWidth 5 / 127 |

RF 6Capacity FullWidth 6 / 152 |

RF 7Capacity FullWidth 7 / 178 |

RF 8Capacity FullWidth 8 / 203 |

|---|---|---|---|---|---|---|---|

12 / 305 |

0.187 / 4.74 |

0.120 / 3.04 |

- |

- |

- |

- |

- |

18 / 458 |

0.156 / 3.96 |

0.105 / 2.66 |

0.218 / 5.54 |

0.250 / 6.35 |

0.312 / 7.92 |

- |

- |

24 / 610 |

0.125 / 2.17 |

0.080 / 2.03 |

0.187 / 4.75 |

0.250 / 6.35 |

0.281 / 7.14 |

0.375 / 9.53 |

0.420 / 10.67 |

30 / 762 |

0.090 / 2.28 |

0.060 / 1.52 |

0.156 / 3.96 |

0.218 / 5.54 |

0.250 / 6.35 |

0.343 / 8.71 |

0.390 / 9.91 |

36 / 915 |

0.060 / 1.52 |

0.035 / 0.88 |

0.125 / 3.18 |

0.187 / 4.75 |

0.218 / 5.54 |

0.312 / 7.92 |

0.343 / 8.71 |

42 / 1220 |

- |

- |

0.094 / 2.39 |

0.156 / 3.96 |

0.187 / 4.75 |

0.281 / 7.14 |

0.312 / 7.92 |

48 / 1220 |

- |

- |

0.063 / 1.60 |

0.125 / 3.18 |

0.156 / 3.96 |

0.250 / 6.35 |

0.281 / 7.14 |

54 / 1524 |

- |

- |

- |

0.094 / 2.39 |

0.125 / 3.18 |

0.218 / 5.54 |

0.250 / 6.35 |

60 / 1524 |

- |

- |

- |

0.063 / 1.60 |

0.094 / 2.39 |

0.187 / 4.75 |

0.218 / 5.54 |

66 / 1829 |

- |

- |

- |

- |

0.094 / 2.39 |

0.156 / 3.96 |

0.187 / 4.75 |

72 / 1829 |

- |

- |

- |

- |

0.094 / 2.39 |

0.156 / 3.96 |

0.187 / 4.75 |

Ratings are for mild steel |

|||||||

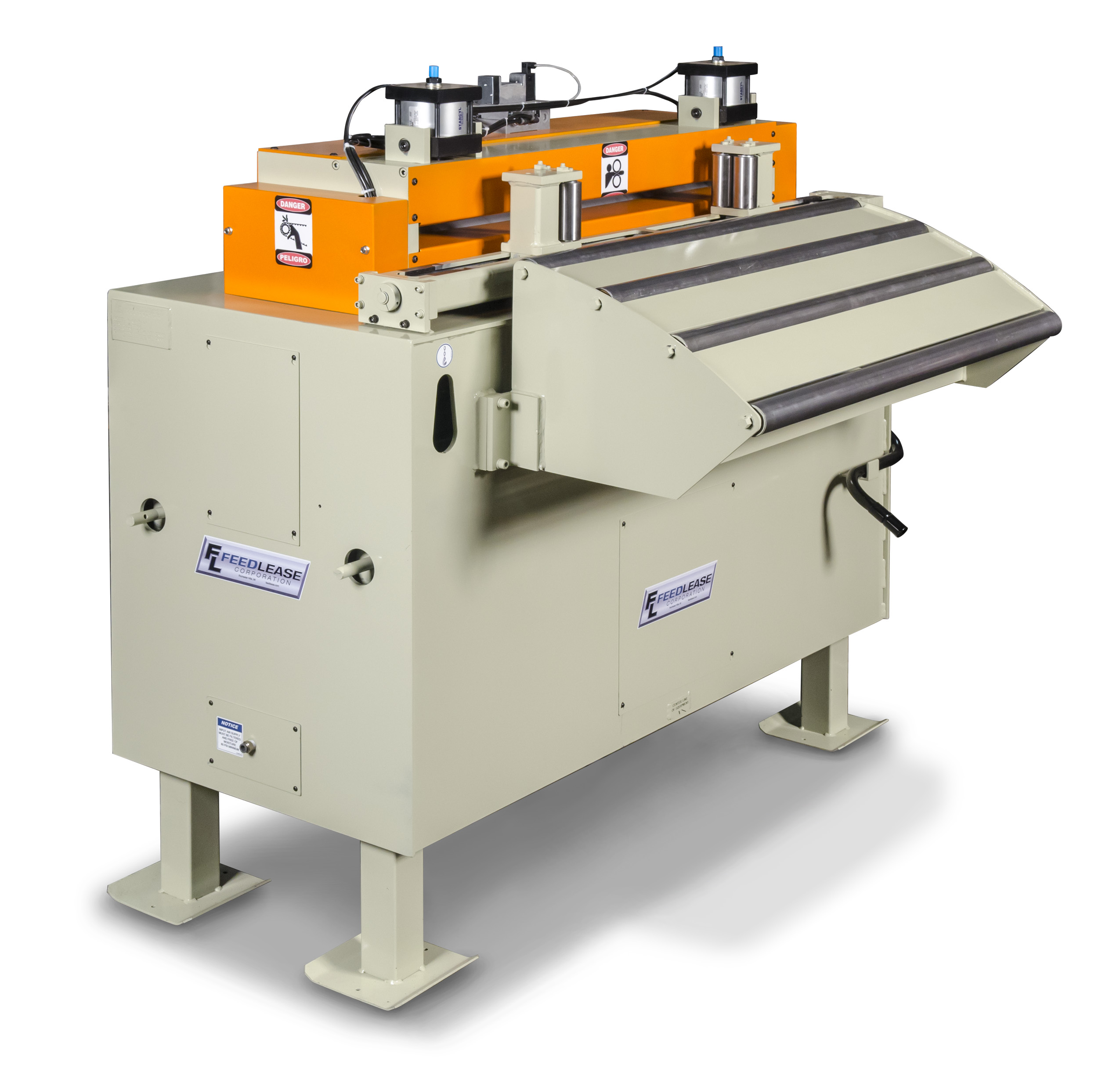

4-Roll Servo Feed

4-roll servo feeds from Universal Feed and Machine can be a good choice when running wide, lighter gauge material. Since four rolls contact the material instead of two, the per-roll pressure can be reduced. For sensitive materials where not marking or stretching the material is critical, a 4-roll feed may be the best choice.

These feeds benefit from a few construction advantages worth noting:

-

The upper feed rolls are trunion-mounted (i.e., rolls pivot rather than go straight up and down as with a slide block design). Trunion mounted upper rolls are the standard on heavy-duty two-roll feeds as they increase the mechanical advantage of the roll and maintain complete gear mesh at all times.

-

Upper rolls work together or independently. Unlike some other 4-roll feeds, Universal Feed and Machine four-roll servo feeds allow all four feed rolls to work together or independently. This adds flexibility to the line.

-

All standard features and options of 2-roll feeds are also available for 4 roll feeds. Discuss your application with a Universal Feed and Machine sales rep to determine if your application is best suited for a 4-roll feed.

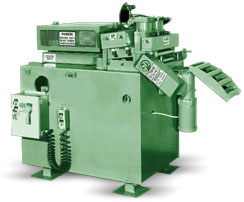

Air Feeds

Air feeds are a simple coil-feeding option best-suited to low volume operations. Universal Feed and Machine air feeds offer a high-strength, cast alloy gripper carriage; pilot release; outboard-mounted electrical controls and adjustable, double-acting air cushions. To simplify job set-up, hand wheel adjustment is provided for rapid stroke length adjustment.

Options include pull-thru straighteners and air saver cylinders. Universal Feed and Machine air feeds are also available in Dual Grip, Zig Zag and Double models.

Standard Equipment

-

Accurate to + .001”

-

Precision fabricated steel feed base

-

High strength cast alloy gripper carriage

-

Pilot pin release electrical circuit

-

Outboard-mounted electrical controls (no reaching over material)

-

Adjustable double-acting air cushion

-

Rapid stroke length adjustment by means of hand wheel

-

Two-roll rear entrance stock guide with entrance vertical guide side shield barrier safety guards

-

Noise control mufflers

-

Guide bar keeper plates industry-standard interchangeable precision parts

-

Mechanical numeric stroke length indicator (FL-4 and larger)

-

Adjustable stroke air saver cylinder (FL-4 and larger)

-

Right angle stroke adjustment by means of hand wheel (FL-4 and larger)

Bar Air Feeds

Universal Feed and Machine bar feeds can be used to handle round, rectangular, I-beam channel and other shaped bars. These feeds can also be designed as push-pull feeds for removing "skeletons" from press or for removing strip material from die.

Specifications

Strokes per minute

|

|

Model FL 2 |

Model FL 2 1/2 |

Model FL 3 1/4 |

Model FL 4 |

Model FL 5 |

Model FL 6 |

|---|---|---|---|---|---|---|

6 |

110 |

90 |

80 |

70 |

60 |

40 |

12 |

90 |

70 |

60 |

55 |

45 |

30 |

18 |

70 |

50 |

50 |

40 |

30 |

20 |

24 |

50 |

40 |

40 |

35 |

25 |

18 |

30 |

35 |

30 |

30 |

30 |

20 |

15 |

36 |

25 |

25 |

25 |

20 |

15 |

12 |

Note: Feed stroke is 5/8 longer than chart indicates. |

||||||

Stock Thickness

|

|

Model FL 2 |

Model FL 2 1/2 |

Model FL 3 1/4 |

Model FL 4 |

Model FL 5 |

Model FL 6 |

|---|---|---|---|---|---|---|

6 |

.156 / .125 |

.187 / .156 |

.218 / .187 |

.340 / .312 |

.375 / .340 |

.375 |

12 |

.125 / .090 |

.156 / .125 |

.187 / .156 |

.312 / .250 |

.340 / .312 |

.375 |

18 |

.090 / .060 |

.125 / .090 |

.156 / .125 |

.250 / .180 |

.312 / .250 |

.375 |

24 |

.060 / .040 |

.090 / .060 |

.125 / .090 |

.200 / .150 |

.250 / .180 |

.312 |

30 |

.040 / .025 |

.060 / .030 |

.090 / .060 |

.170 / .120 |

.180 / .150 |

.250 |

36 |

- |

.045 / .025 |

.060 / .030 |

.120 / .070 |

.150 / .120 |

.187 |

Note: Material is 1 wider than chart indicates. FL 6 information shown with straightener only. |

||||||

Servo Driven Feeds

The RF Series

The RF Series feeds are ideal for medium to heavy duty stamping and cut-to-length applications. This series comes in six sizes, ranging from 2.5" to 8" diameter feed rolls in an array of coil widths. High torque servo motors that drive either planetary or helical-bevel reducers make the RF series both powerful and precise.

RF-2.5 Series Servo Feeds

RF-2.5 Series servo feeds are designed to provide an economical means of employing servo feed technology on smaller presses without sacrificing quality, accuracy, durability or power.

The mechanical design of the RF-2.5 Series sets it apart. Consider the standard features on every model: Maintenance-Free AC brushless servo motor; a Kevlar non-stretch timing belt transfers power to the feed rolls; solid, full width, matte finish feed rolls; adjustable stroke air cylinder for roll pressure and pilot release; pivoting upper roll assembly maintains full gear mesh at any thickness; heavy duty, “C” frame, Slide & Clamp edge guide; slotted press mounting plate; entrance curve section and remote jog pendant with four modes.

Featured Videos:

RFZZ-3-24 Zig-Zag Roll Feed

Material Support Table

All RF-2.5 Series servo feeds can be equipped with an optional, adjustable height cabinet base.

All RF Series servo are available in a Push-Pull configuration and operate synchronously from a single control.

Designed for blanking out diameters, zig/zag servo feeds can be programmed to perform from two to multiple out blanks, typically saving at least 8% in material costs.

Servo Feed Specifications

RF 2.5 Series

Model RF-2.5 (63.5)Width (in/mm) |

CapacityFull Width (in/mm) |

CapacityWith PTS (in/mm) |

|---|---|---|

6 / 152.4 |

0.187 / 4.75 |

0.120 / 3.05 |

12 / 305 |

0.156 / 3.96 |

0.105 / 2.67 |

18 / 458 |

0.125 / 3.18 |

0.080 / 2.03 |

24 / 610 |

0.094 / 2.39 |

0.060 / 1.52 |

30 / 762 |

0.063 / 1.60 |

0.035 / 0.89 |

Ratings are for mild steel |

||

-

Standard Features

-

Optional Features

- Remote jog with jog-to-length

- Entrance curve section for material support

- Heavy-duty, slide & clamp edge guides

- Color Touch screen operator interface

- 200 job memory

- On-the-fly, micro adjust feature

- English/Spanish, Inch/Metric

- Batch counter

RF Series Servo Feeds

The exceptional mechanical design of the RF Series sets it apart from many other feed designs. Horizontal tie-bars provide significant structural rigidity. Feed rolls are full diameter across the entire rated width of the feed. Sealed-for-life spherical roller bearings are used to support the feed rolls.

All RF Series feeds can be equipped with a pull-thru straightener.

The rolls raise and lower on a pivot, rather than up and down in a slide block, to ensure full gear mesh regardless of the thickness of the material.

The roll pressure is applied by two adjustable-stroke pneumatic cylinders. Roll pressure is adjusted by a supplied regulator. The same cylinders are also used for the pilot release of the upper feed roll. These cylinders are positioned well past the center point of the rolls to provide leverage for optimum pressure to the roll.

-

Standard Features

-

Optional Features

-

Adjustable height cabinet (optional on RF-2.5 and RF 3)

-

Remote jog pendant with jog-to-length

-

Curve section or chute support bracket

-

Heavy-duty adjustable entry guides

-

Color touch screen Operator

-

200 Job Memory

-

On-the-fly, micro-adjust feature

-

English/Spanish, Inch/Metric

-

Feed complete output

-

Batch counter

Servo Feed Controls

Universal Feed and Machine Corporation is proud to employ top quality controls on every servo feed. Universal Feed and Machine servo feeds utilize, as standard, a Control Techniques (Emerson) drive for superior performance. Since no components of the electronic system are proprietary, our customers have the option of using their local distributor for any replacement parts.

Optional I/O are available for more advanced systems. For example, our optional Line Automation allows any powered axis to be stored in the job recipe and automatically set to position when a given job is loaded.

1000 Series control, standard on RF 2.5 and RF 3 models, with color touch screen operator interface.

5000 Series control, standard on all RF 4 through RF 8 models, with color touch screen operator interface.

-

Standard Features

-

Optional Features

-

Brushless servo motors

-

Servo feeds up to 150 HP

-

Jog forward/reverse - Slow/Fast

-

Jog-to-length - Slow/Fast

-

Auto/Manual mode

-

Serial interface available

-

Feed complete output (optional on RF 2.5 and RF 3 Series)

-

200 recipe storage

-

Color touch screen operator interface

-

Micro adjust plus/minus

-

Setup mode password protection

-

Feed length to 0 to 999.999

-

Batch and part count

-

Press too fast fault

-

E-Stop

Dual Roll Vertical Guides

"No Tools Required" Passline Height Adjustment

Hand Crank Adjustable Vertical Guides

Floor Stand with Guide Bars

Motorized Vertical Guides

Anti-Back-up Rolls

Pull-Through Straightener

Material Support Table

Heavy Duty Pull-Thru Straightener With Pilot Release

RF Series

Width (in/mm) |

RF 3CapacityFull Width |

RF 3CapacityWith PTS |

RF 4Capacity FullWidth 4 / 101 |

RF 5Capacity FullWidth 5 / 127 |

RF 6Capacity FullWidth 6 / 152 |

RF 7Capacity FullWidth 7 / 178 |

RF 8Capacity FullWidth 8 / 203 |

|---|---|---|---|---|---|---|---|

12 / 305 |

0.187 / 4.74 |

0.120 / 3.04 |

- |

- |

- |

- |

- |

18 / 458 |

0.156 / 3.96 |

0.105 / 2.66 |

0.218 / 5.54 |

0.250 / 6.35 |

0.312 / 7.92 |

- |

- |

24 / 610 |

0.125 / 2.17 |

0.080 / 2.03 |

0.187 / 4.75 |

0.250 / 6.35 |

0.281 / 7.14 |

0.375 / 9.53 |

0.420 / 10.67 |

30 / 762 |

0.090 / 2.28 |

0.060 / 1.52 |

0.156 / 3.96 |

0.218 / 5.54 |

0.250 / 6.35 |

0.343 / 8.71 |

0.390 / 9.91 |

36 / 915 |

0.060 / 1.52 |

0.035 / 0.88 |

0.125 / 3.18 |

0.187 / 4.75 |

0.218 / 5.54 |

0.312 / 7.92 |

0.343 / 8.71 |

42 / 1220 |

- |

- |

0.094 / 2.39 |

0.156 / 3.96 |

0.187 / 4.75 |

0.281 / 7.14 |

0.312 / 7.92 |

48 / 1220 |

- |

- |

0.063 / 1.60 |

0.125 / 3.18 |

0.156 / 3.96 |

0.250 / 6.35 |

0.281 / 7.14 |

54 / 1524 |

- |

- |

- |

0.094 / 2.39 |

0.125 / 3.18 |

0.218 / 5.54 |

0.250 / 6.35 |

60 / 1524 |

- |

- |

- |

0.063 / 1.60 |

0.094 / 2.39 |

0.187 / 4.75 |

0.218 / 5.54 |

66 / 1829 |

- |

- |

- |

- |

0.094 / 2.39 |

0.156 / 3.96 |

0.187 / 4.75 |

72 / 1829 |

- |

- |

- |

- |

0.094 / 2.39 |

0.156 / 3.96 |

0.187 / 4.75 |

Ratings are for mild steel |

|||||||

4-Roll Servo Feed

4-roll servo feeds from Universal Feed and Machine can be a good choice when running wide, lighter gauge material. Since four rolls contact the material instead of two, the per-roll pressure can be reduced. For sensitive materials where not marking or stretching the material is critical, a 4-roll feed may be the best choice.

These feeds benefit from a few construction advantages worth noting:

-

The upper feed rolls are trunion-mounted (i.e., rolls pivot rather than go straight up and down as with a slide block design). Trunion mounted upper rolls are the standard on heavy-duty two-roll feeds as they increase the mechanical advantage of the roll and maintain complete gear mesh at all times.

-

Upper rolls work together or independently. Unlike some other 4-roll feeds, Universal Feed and Machine four-roll servo feeds allow all four feed rolls to work together or independently. This adds flexibility to the line.

-

All standard features and options of 2-roll feeds are also available for 4 roll feeds. Discuss your application with a Universal Feed and Machine sales rep to determine if your application is best suited for a 4-roll feed.

Air Feeds

Air feeds are a simple coil-feeding option best-suited to low volume operations. Universal Feed and Machine air feeds offer a high-strength, cast alloy gripper carriage; pilot release; outboard-mounted electrical controls and adjustable, double-acting air cushions. To simplify job set-up, hand wheel adjustment is provided for rapid stroke length adjustment.

Options include pull-thru straighteners and air saver cylinders. Universal Feed and Machine air feeds are also available in Dual Grip, Zig Zag and Double models.

Standard Equipment

-

Accurate to + .001”

-

Precision fabricated steel feed base

-

High strength cast alloy gripper carriage

-

Pilot pin release electrical circuit

-

Outboard-mounted electrical controls (no reaching over material)

-

Adjustable double-acting air cushion

-

Rapid stroke length adjustment by means of hand wheel

-

Two-roll rear entrance stock guide with entrance vertical guide side shield barrier safety guards

-

Noise control mufflers

-

Guide bar keeper plates industry-standard interchangeable precision parts

-

Mechanical numeric stroke length indicator (FL-4 and larger)

-

Adjustable stroke air saver cylinder (FL-4 and larger)

-

Right angle stroke adjustment by means of hand wheel (FL-4 and larger)

Bar Air Feeds

Universal Feed and Machine bar feeds can be used to handle round, rectangular, I-beam channel and other shaped bars. These feeds can also be designed as push-pull feeds for removing "skeletons" from press or for removing strip material from die.

Specifications

Strokes per minute

|

|

Model FL 2 |

Model FL 2 1/2 |

Model FL 3 1/4 |

Model FL 4 |

Model FL 5 |

Model FL 6 |

|---|---|---|---|---|---|---|

6 |

110 |

90 |

80 |

70 |

60 |

40 |

12 |

90 |

70 |

60 |

55 |

45 |

30 |

18 |

70 |

50 |

50 |

40 |

30 |

20 |

24 |

50 |

40 |

40 |

35 |

25 |

18 |

30 |

35 |

30 |

30 |

30 |

20 |

15 |

36 |

25 |

25 |

25 |

20 |

15 |

12 |

Note: Feed stroke is 5/8 longer than chart indicates. |

||||||

Stock Thickness

Model FL 2 |

Model FL 2 1/2 |

Model FL 3 1/4 |

Model FL 4 |

Model FL 5 |

Model FL 6 |

|

|---|---|---|---|---|---|---|

6 |

.156 / .125 |

.187 / .156 |

.218 / .187 |

.340 / .312 |

.375 / .340 |

.375 |

12 |

.125 / .090 |

.156 / .125 |

.187 / .156 |

.312 / .250 |

.340 / .312 |

.375 |

18 |

.090 / .060 |

.125 / .090 |

.156 / .125 |

.250 / .180 |

.312 / .250 |

.375 |

24 |

.060 / .040 |

.090 / .060 |

.125 / .090 |

.200 / .150 |

.250 / .180 |

.312 |

30 |

.040 / .025 |

.060 / .030 |

.090 / .060 |

.170 / .120 |

.180 / .150 |

.250 |

36 |

- |

.045 / .025 |

.060 / .030 |

.120 / .070 |

.150 / .120 |

.187 |

Note: Material is 1 wider than chart indicates. FL 6 information shown with straightener only. |

||||||