Why Otinus?

At Otinus, we pride ourselves on delivering innovative and reliable solutions tailored to meet your needs. Our years of expertise, combined with cutting-edge technology, ensure that every product we offer stands for quality and precision. Whether you’re looking for advanced machinery or expert support, Otinus is your trusted partner in success.

Choose Otinus for unmatched performance, durability, and a commitment to excellence that drives your business forward

Let our team show you the innovative products and features Otinus has to offer.

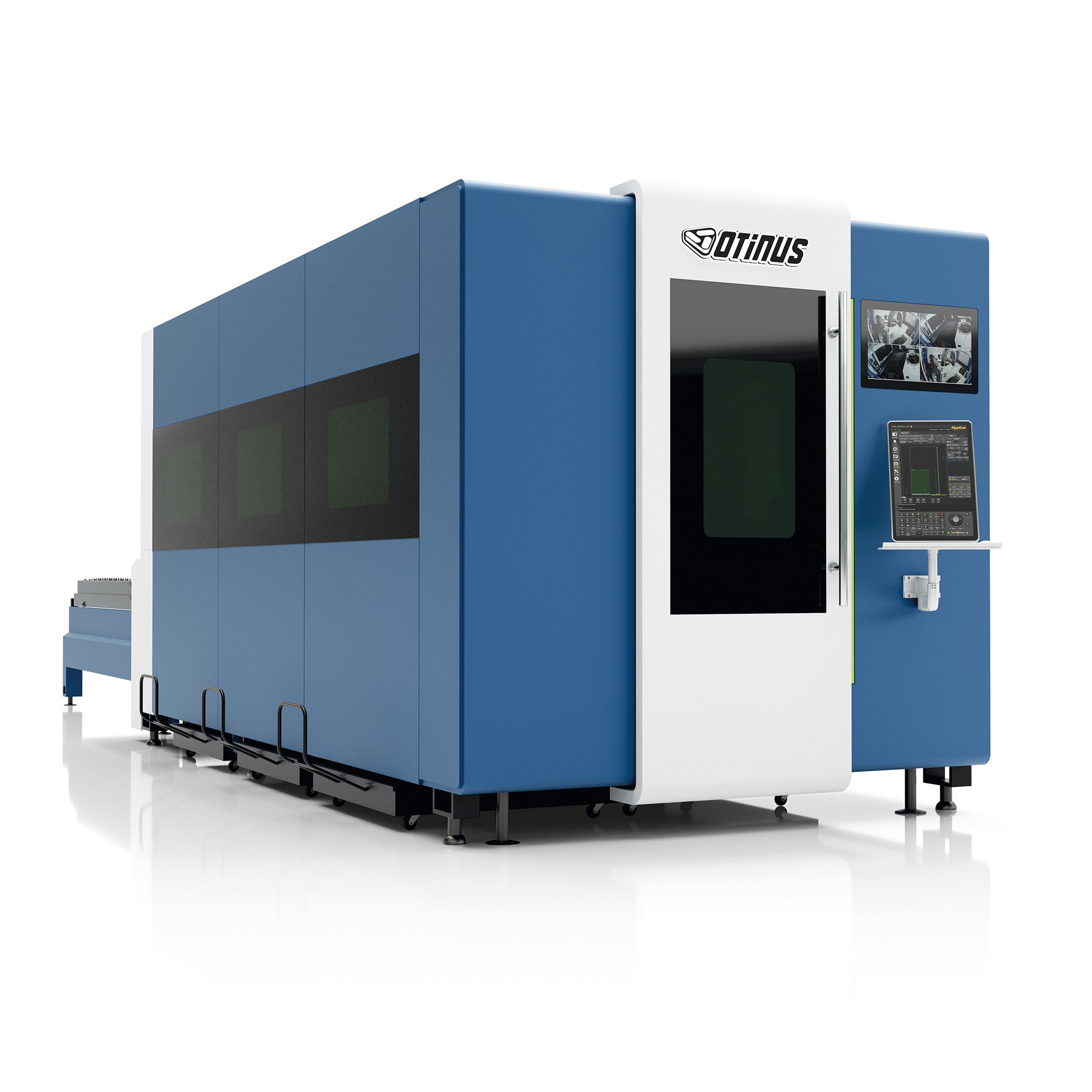

Fiber Laser cutting machine

Information:

Working table dimensions: from 5x10 or 10x20 feet

Laser source output power: from 1 kW to 30 kW

Exchangeable table

Nesting software for waste reduction

Zonal fume extraction system

Components from renowned brands, including Schneider, Fuji Electric, Motovario

Nearly maintenance-free operation of the laser source

Ability to cut various materials, including mild steel, aluminum, stainless steel, and brass.

Standard equipment:

Voltage stabilizer

CypNest nesting software

Optional equipment:

Torsion head - 4th axis

Automatic nitrogen pressure control

Tube cutter

IPG laser source

Precitec cutting head

Contact our sales department at sales@heritagemachinery.com or call 248-693-4796

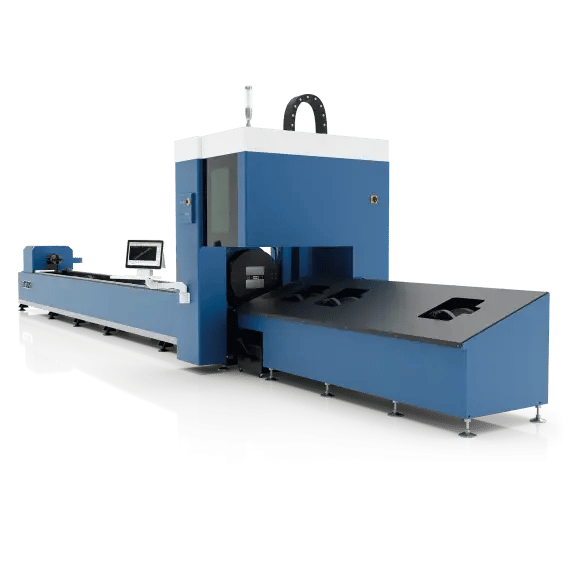

Fiber Laser Cutting Machine with rotary tube

Working table length: 20 feet

Laser source output power: from 1 kW up to 6 kW

Max chuck sizes: 6 inches, 9 inches or 14 inches

Unloading table

Automatic feeder and Bevel Cutting Head options

Nesting software for waste reduction

Components from renowned brands, including Schneider, Fuji Electric, Motovario

Nearly maintenance-free operation of the laser source

Ability to cut various materials, including mild steel, aluminum, stainless steel, and brass.

Voltage stabilizer

Laser source chiller

Bevel head 45°

TubesT software

IPG laser source

Precitec cutting head

Unloading table 10 feet

Guillotine shears

Blades for cutting mild steel

Simple controller

Double-sided blades for less frequent sharpening

Hydraulic driven hold-downs for sheet clamping along the entire cutting length

Supports and ball transfer units to facilitate work

Laser cutting line indicator

Guards ensuring operator safety

Manual clearance adjustment – ability to adjust the process for different material thicknesses

Machine workspace lighting

Rear ramp with ball transfers for easy part drop to the floor

Blades capable of cutting up to 1 inch

Working table lengths: up to 20 feet

Blades for cutting stainless steel

PCS - Pressure Control System

OCS - Oil Cooling System

Rexroth hydraulic valve

Schneider electrical components

Optional equipment:

Stainless steel blade

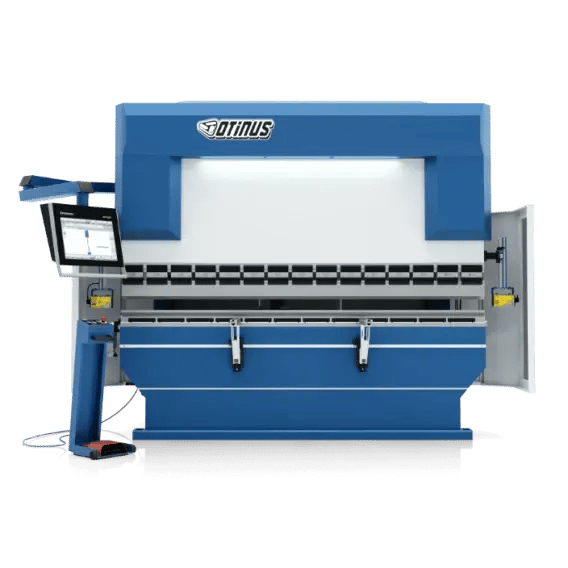

Hydraulic Press Brake

Information:

Working table lengths: from 4 feet to 20 feet

Bending force: up to 250 tons

Controllers: Otinus OT-41 or Delem DA-58T

Front laser safety system: Fiessler AKAS-II (Germany)

Hydraulic system: HAWE (Germany)

Front supports on linear guides

Universal lower die

Amada-Promecam tool clamping system

Quick clamping system

Movements in all axes controlled by servomotors

User-friendly interface

Front supports for sheet handling

Oil cooling system (OCS)

Light curtains

Limit switches

Safety guards

Standard equipment:

Lower die segmented as the upper die + die holder

AMADA type double punch clamping

Independent control of Y1 and Y2 axes

Automatic control of R-axis

2 front supports on linear guides

Optional equipment:

Manual crowning

Automatic crowning

Plasma cutting machine

Working table dimensions: 5x10 feet

Equipped with Hypertherm plasma sources — a world leader in plasma cutting technology

Fully welded steel machine frame – ensuring durability and trouble-free operation for many years

Align Material System – automatic correction of material positioning angle

Torch height controller – integrated cutting height control system

Access to training materials on the Otinus Academy e-learning platform

Ventilated table

Hypertherm Powermax sources: from 45A up to 125A

Anti-Collision System

Set of ready-to-use CAD drawings

Operator’s starter kit (safety glasses, lithium grease, joypad controller, WI-FI module)

Laser pointer

X-axis extended gantry 20 inches

X/Y-axis servo-stepper motors

Gas torch: cutting up to 30 inches

Plasma & Gas Cutting Machine

Working table dimensions: 5x10 feet

Equipped with Hypertherm plasma sources — a world leader in plasma cutting technology

Fully welded steel machine frame – ensuring durability and trouble-free operation for many years

Align Material System – automatic correction of material positioning angle

Torch height controller – integrated cutting height control system

Access to training materials on the Otinus Academy e-learning platform

Ventilated table

Hypertherm Powermax sources: from 45A up to 125A

Harris torch and gas control panel

Anti-Collision System

Set of ready-to-use CAD drawings

Operator’s starter kit (safety glasses, lithium grease, joypad controller, WI-FI module)

Laser pointer

X-axis extended gantry 20 inches

X/Y-axis servo-stepper motors

Automatic spark lighter

Gas torch: cutting up to 30 inches

Press Brake

Working table lengths: from 4 feet up to 20 feet

Bending force: from 40 tones up to 880 tones

Controllers: Delem DA-66T or DA-69T

Axis number variation: from 4+1 up to 8+1

Fiessler Akas light curtains

Amada-Promecam tool clamping system

Quick clamping system

Movements in all axes controlled by servomotors

User-friendly interface

Front supports for sheet handling

Oil cooling system (OCS)

Hydraulic system: HAWE (Germany)

Light curtains

Limit switches

Safety guards

Controller: Delem DA-66T

Y1+Y2+X+R axes (servo drives)

Automatic crowning

Promecam rapid clamp system

2 backgauge fingers

2 front supports on linear guides

AKAS II light curtains

Controller: Delem DA-69T

2 front supports on linear guides

Guillotine shears

Reinforced and more solid construction

Intuitive CNC controllers: CybTouch8 or ELGO P40T

Extended front supports with protractors

Extended front supports with protractors

Supports and ball transfer units at the front table and rear ramp

Laser cutting line indicator

Additional lifts on the rear ramp

Guards and photocells ensuring operator safety

Automatic clearance adjustment – ability to adapt to different material thicknesses

Machine workspace lighting

Blades: up to 1 inch thick

Working table lengths: up to 20 feet

Blades for cutting stainless steel

Automatic blade gap adjustment