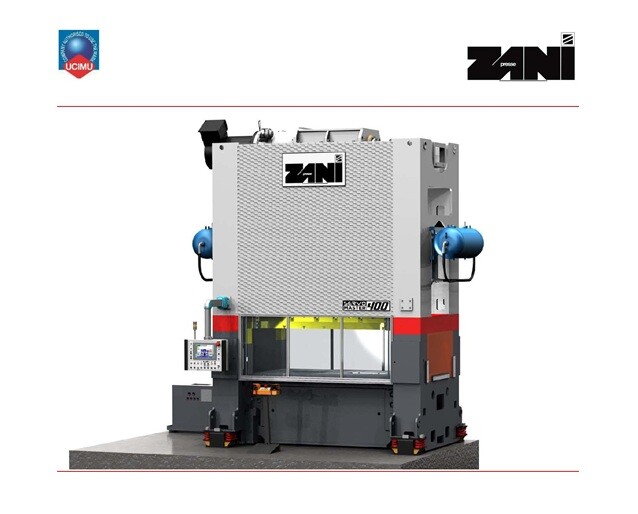

ZANI Servo Smart Series Straight Side Presses.

The Servo Smart series of presses are built with the exceptional design qualities and characteristics that have come define our machines. Through the utilization of cutting edge servo technology these machines provide enhanced capabilities that surpass standard presses and offer the flexibility to address a more broader range of materials and parts.

Our design process incorporates the use of a 3D printer to create scale models

of the machines. This allows us to efficiently and safely validate each design,

assess potential interferences from moving parts, evaluate the feasibility of

assembly sequences, and ensure accessibility to various areas for maintenance

activities.

The Smart Servo Series are mono-block frame, welded steel construction featuring two point suspension with capacities from 200 to 400 tons and a range of stroke lengths and is an excellent choice for progressive or drawing applications.

Standard Features Include:

-

Siemens Servo Drive Technology.

- SERVO motor/s and safety brake

- Balancing cylinders

- Hydraulic overload safety device

- Standard bolster plate with “T” slots type T28 pitch 250 mm.

- Pneumatic equipment with filter-reducer unit, air accumulator tanks with pressure control switch

- Motorized ram vertical adjustment and digital read-out of the screw achieved position

- Lubrication system with oil recovery

- Electrical system equipped with a SIEMENS SAFETY PLC for the press safety functions control

- Oil bath gears

- Press functions control system FIDO PRESS ZANI, composed as follows:

- SIEMENS PLC S7, 1500 F series

- SIEMENS PC PANEL

- 15” TOUCH DISPLAY 1024x768

- 4 USB (back) + 1 USB (Front)

- 8 electronic cams

- 8 inputs for tool safety

- Tele-Service VPN connection

- Electronic load monitoring on the con-rods with control of the hydraulic overload

- Bronze bushings thermal control

- Pendant and swinging console |__|left |__|right

- Two-hands mobile control, a TDC stop push button, an emergency push button, and an alarm reset button

- Handwheel with manual mini keyboard

- Safety guards, fulfilling EC regulations:

- vertical movement front and rear gates

- fixed side fences